Nissan Pathfinder. Manual - part 642

FL-24

< DISASSEMBLY AND ASSEMBLY >

FUEL LEVEL SENSOR UNIT

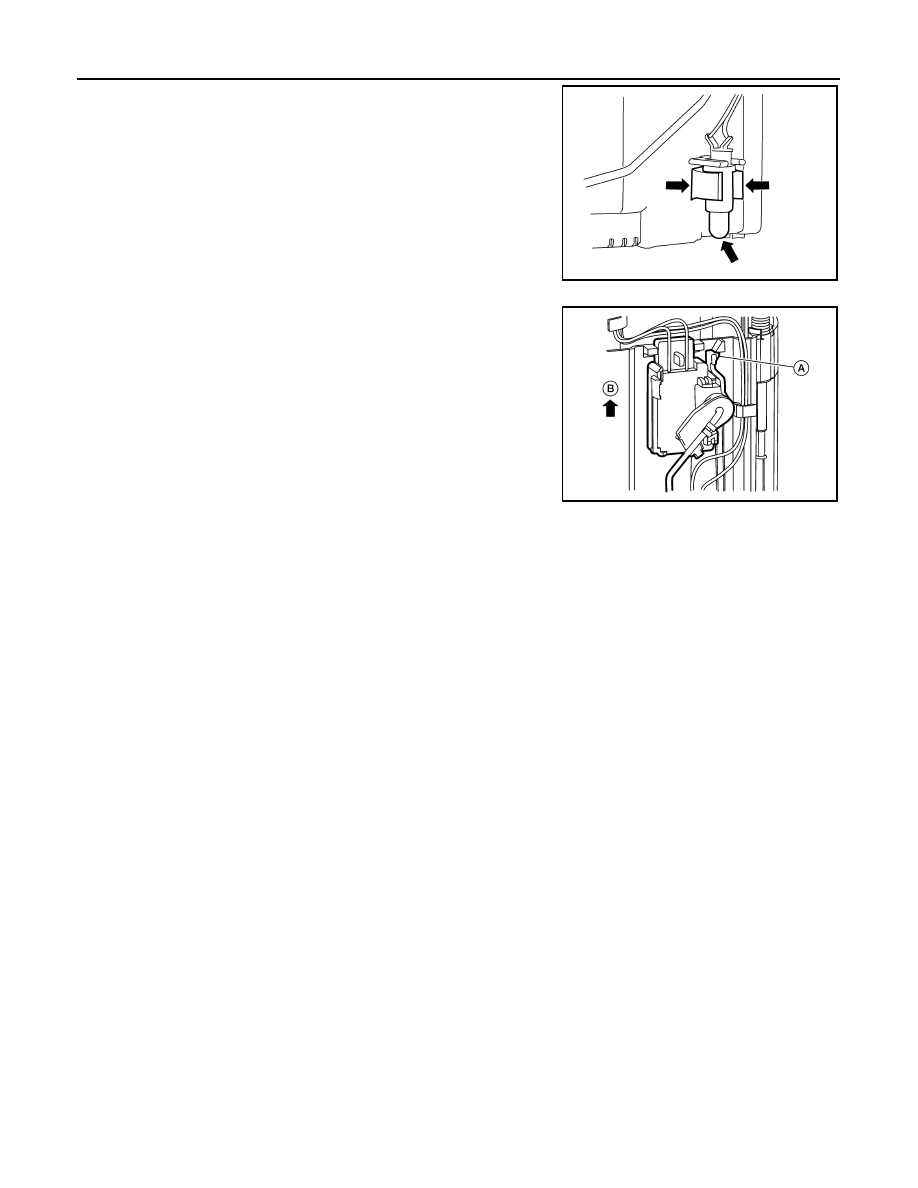

2. Release the two clips and remove the fuel tank temperature

sensor from the pump assembly.

3. Release the tab (A) and slide the fuel level sensor unit and float

arm assembly (B) up to remove.

Assembly

NOTE:

Assembly is the reverse order of disassembly.

• Ensure proper placement of the wires to the correct terminals and correct wire routing to the terminals.

• After connecting terminals, ensure they are securely locked and can not be pulled out.

• When installing the fuel level sensor unit, push down until the tab is locked into place.

ALBIA0670ZZ

ALBIA0749ZZ