Murano Cross Cabriolet Z51 (2012 year). Manual - part 27

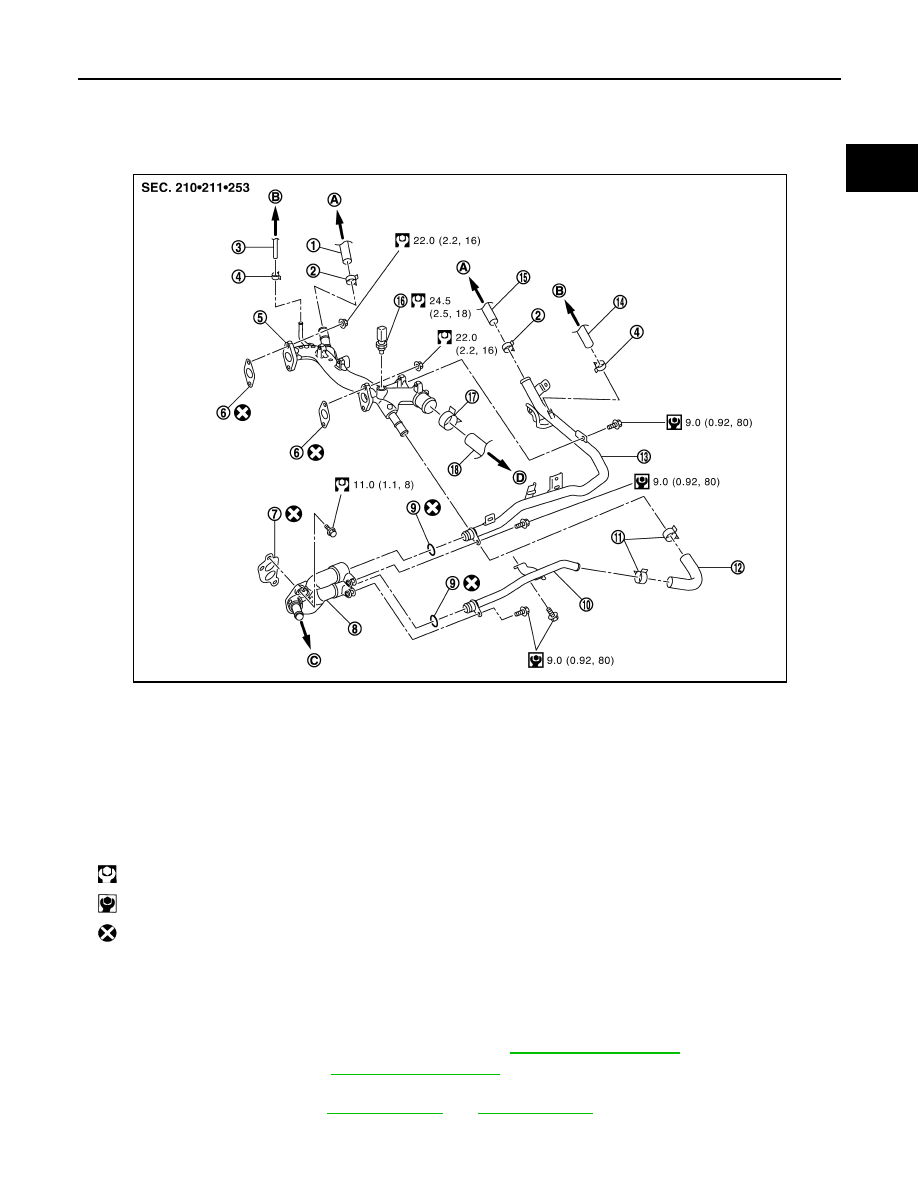

WATER OUTLET AND WATER PIPING

CO-27

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

K

L

M

A

CO

N

P

O

WATER OUTLET AND WATER PIPING

Exploded View

INFOID:0000000007565999

Removal and Installation

INFOID:0000000007566000

REMOVAL

1.

Remove air duct (inlet), radiator core support covers (RH and LH), air cleaner cases (upper and lower)

with mass air flow sensor and air duct assembly. Refer to

2.

Remove engine cover. Refer to

.

3.

Drain engine coolant from radiator drain plug at the bottom of radiator, and from water drain plug at the

front of cylinder block. Refer to

and

.

CAUTION:

1.

Heater hose

2.

Clamp

3.

Water hose

4.

Clamp

5.

Water outlet

6.

Gasket

7.

Gasket

8.

Water connector

9.

O-ring

10. Water bypass pipe

11.

Clamp

12.

Water hose

13. Heater pipe

14.

Water hose

15.

Heater hose

16. Engine coolant temperature sensor

17.

Clamp

18.

Radiator hose (upper)

A.

To heater core

B.

To electric throttle control actuator

C.

To oil cooler

D.

To radiator

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: Always replace after every disassembly.

JPBIA1691GB

Revision: 2013 February

2012 Murano CrossCabriolet