Nissan Murano Z50 (2005 year). Manual - part 178

HEADLAMP - XENON TYPE -

LT-35

C

D

E

F

G

H

I

J

L

M

A

B

LT

Revision: 2005 August

2005 Murano

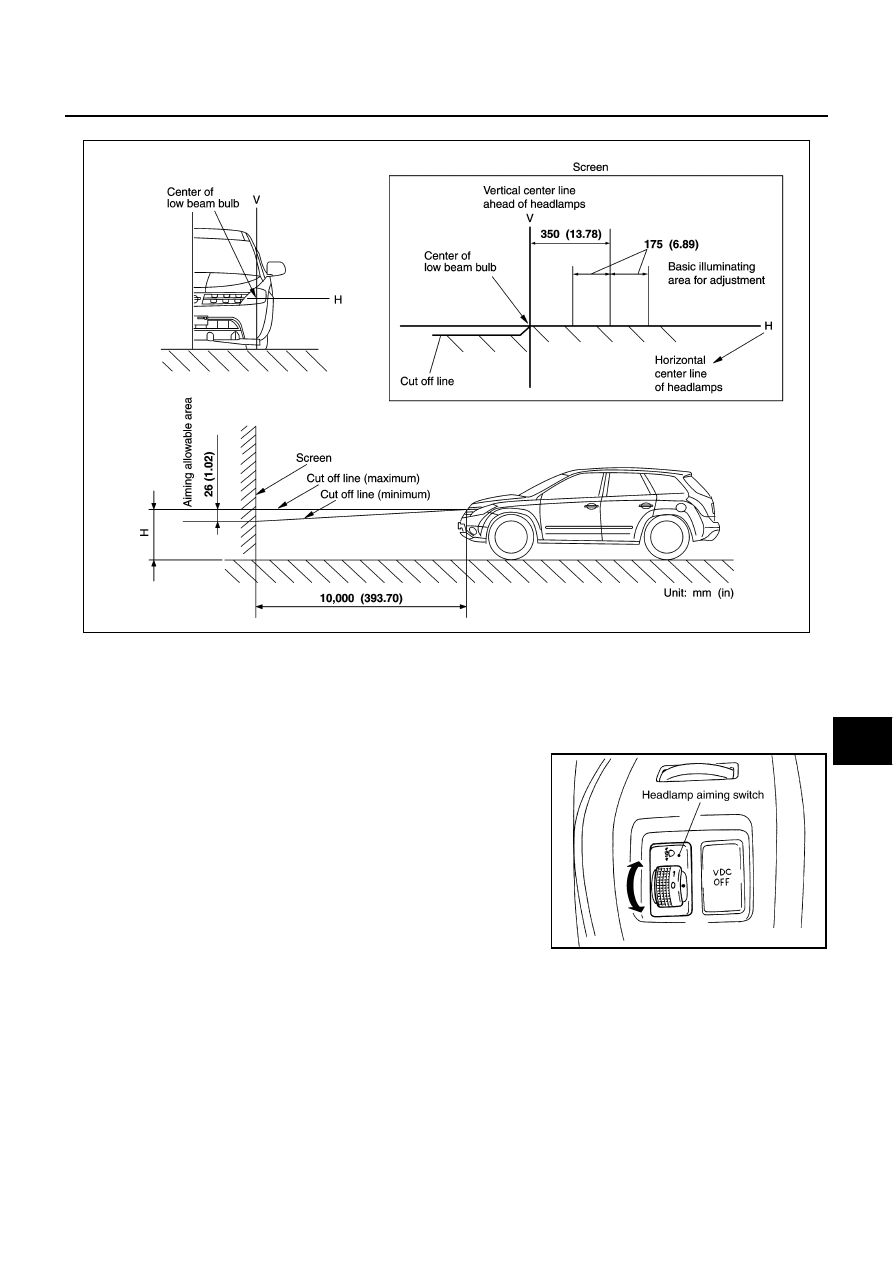

ADJUSTMENT USING AN ADJUSTMENT SCREEN (LIGHT/DARK BORDERLINE)

If the vehicle front body has been repaired and/or the headlamp assembly has been replaced, check aiming.

Use the aiming chart shown in the figure.

●

Basic illumination area for adjustment should be within the range shown on the aiming chart.

Adjust headlamp accordingly.

CAUTION:

Be sure aiming switch is set to “0” when performing aiming

adjustment.

PKIB2152E

PKIB2153E