Nissan Murano Z50 (2005 year). Manual - part 126

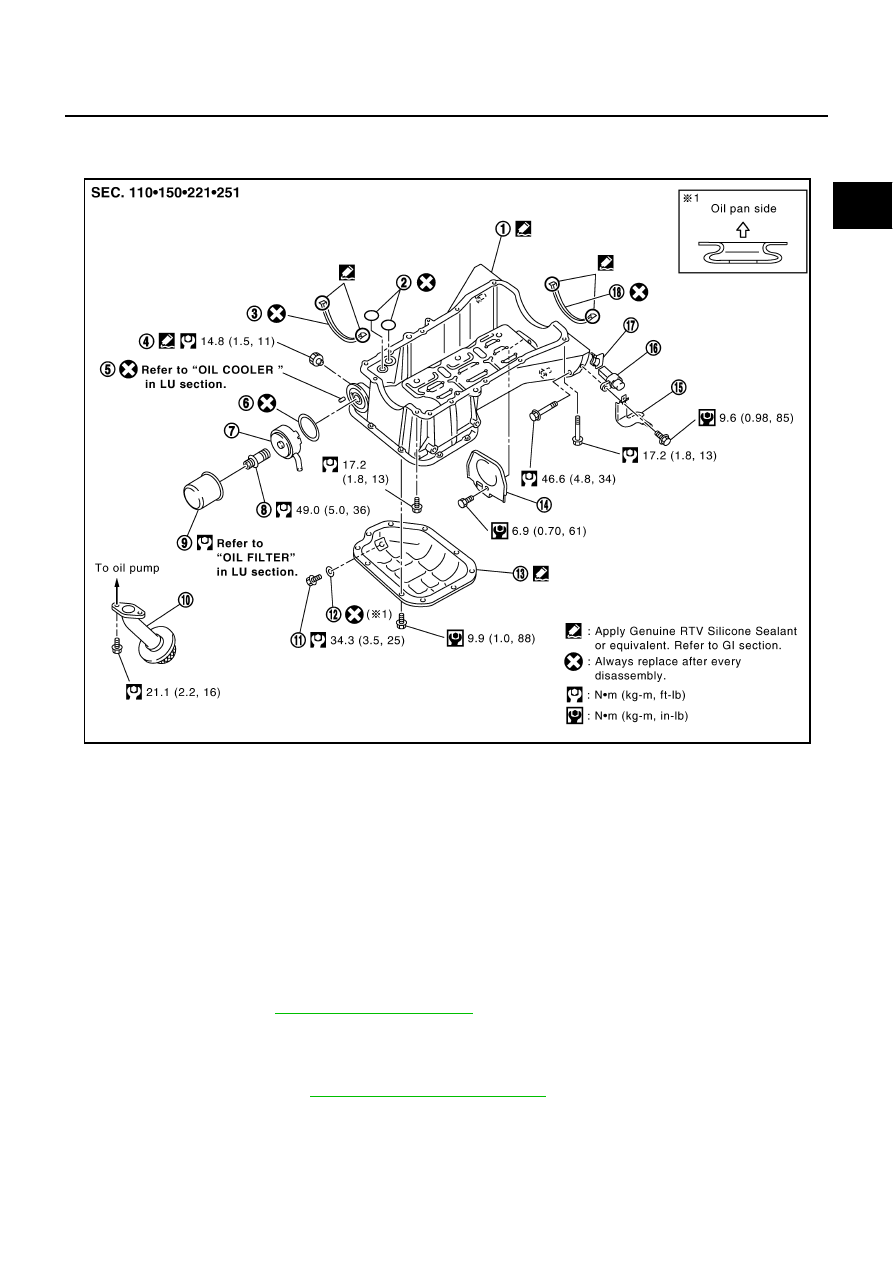

OIL PAN AND OIL STRAINER

EM-29

C

D

E

F

G

H

I

J

K

L

M

A

EM

Revision: 2005 August

2005 Murano

OIL PAN AND OIL STRAINER

PFP:11110

Removal and Installation

ABS00FAF

REMOVAL

2WD Model

WARNING:

To avoid the danger of being scalded, do not drain engine oil when the engine is hot.

NOTE:

When removing oil pan (lower) or oil strainer only, take step 1 then step 10 and 11.

1.

.

CAUTION:

●

Perform this step when the engine is cold.

●

Do not spill engine oil on drive belts.

2.

Drain engine coolant. Refer to

CO-9, "Changing Engine Coolant"

.

CAUTION:

●

Perform this step when engine is cold.

●

Do not spill engine coolant on drive belts.

3.

Remove following parts:

1.

Oil pan (upper)

2.

O-ring

3.

Oil pan gasket (front)

4.

Oil pressure switch

5.

Relief valve

6.

O-ring

7.

Oil cooler

8.

Connector bolt

9.

Oil filter

10. Oil strainer

11.

Drain plug

12. Drain plug washer

13. Oil pan (lower)

14. Rear plate cover

15. Harness bracket (2WD models)

16. Crankshaft position sensor (POS)

17. Seal rubber

18. Oil pan gasket (rear)

PBIC4167E