Nissan Murano Z51 (2008 year). Manual - part 269

MWI

DIAGNOSIS SYSTEM (METER)

MWI-33

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

M

B

A

O

P

DIAGNOSIS SYSTEM (METER)

Diagnosis Description

INFOID:0000000003415506

SELF-DIAGNOSIS MODE

• Information display LCD segment operation can be checked in self-diagnosis mode.

• Meters/gauges can be checked in self-diagnosis mode.

OPERATION PROCEDURE

1.

Turn ignition switch ON, and switch the trip meter to “trip A” or “trip B”.

NOTE:

If the diagnosis function is activated with “trip A” displayed, the mileage on “trip A” is reset to “0000.0”.

(The same way for “trip B”.)

2.

Turn ignition switch OFF.

3.

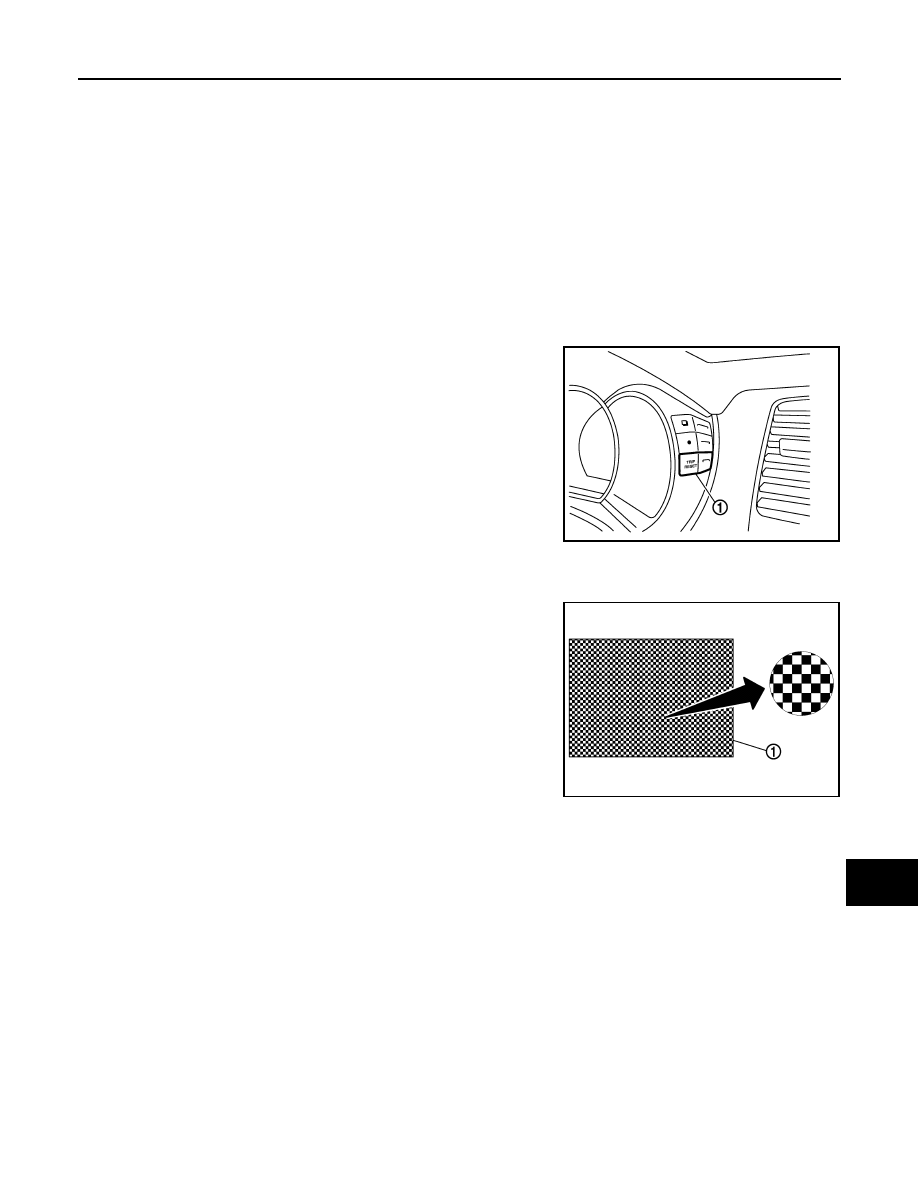

While pressing the trip reset switch (1), turn ignition switch ON

again.

4.

Make sure that the trip meter displays “0000.0”.

5.

Press the trip reset switch at least 3 times. (Within 7 seconds

after the ignition switch is turned ON.)

6.

The unified meter control unit is turned to self-diagnosis mode.

• All the segments on the odo/trip meter and shift position indicator illuminate.

• The segment dots of the information display LCD (1) blink

alternately.

• Engine coolant temperature gauge and fuel gauge return to

zero, simultaneously.

NOTE:

• Check combination meter power supply and ground circuit when the self-diagnosis mode of the combi-

nation meter does not start. Replace combination meter if abnormal.

• If any of the segments are not displayed, replace combination meter.

JPNIA0743ZZ

JPNIA0766ZZ

Revision: 2008 October

2009 Murano