Nissan Murano Z51 (2008 year). Manual - part 201

EXL-324

< SYMPTOM DIAGNOSIS >

[HALOGEN TYPE]

EXTERIOR LIGHTING SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

EXTERIOR LIGHTING SYSTEM SYMPTOMS

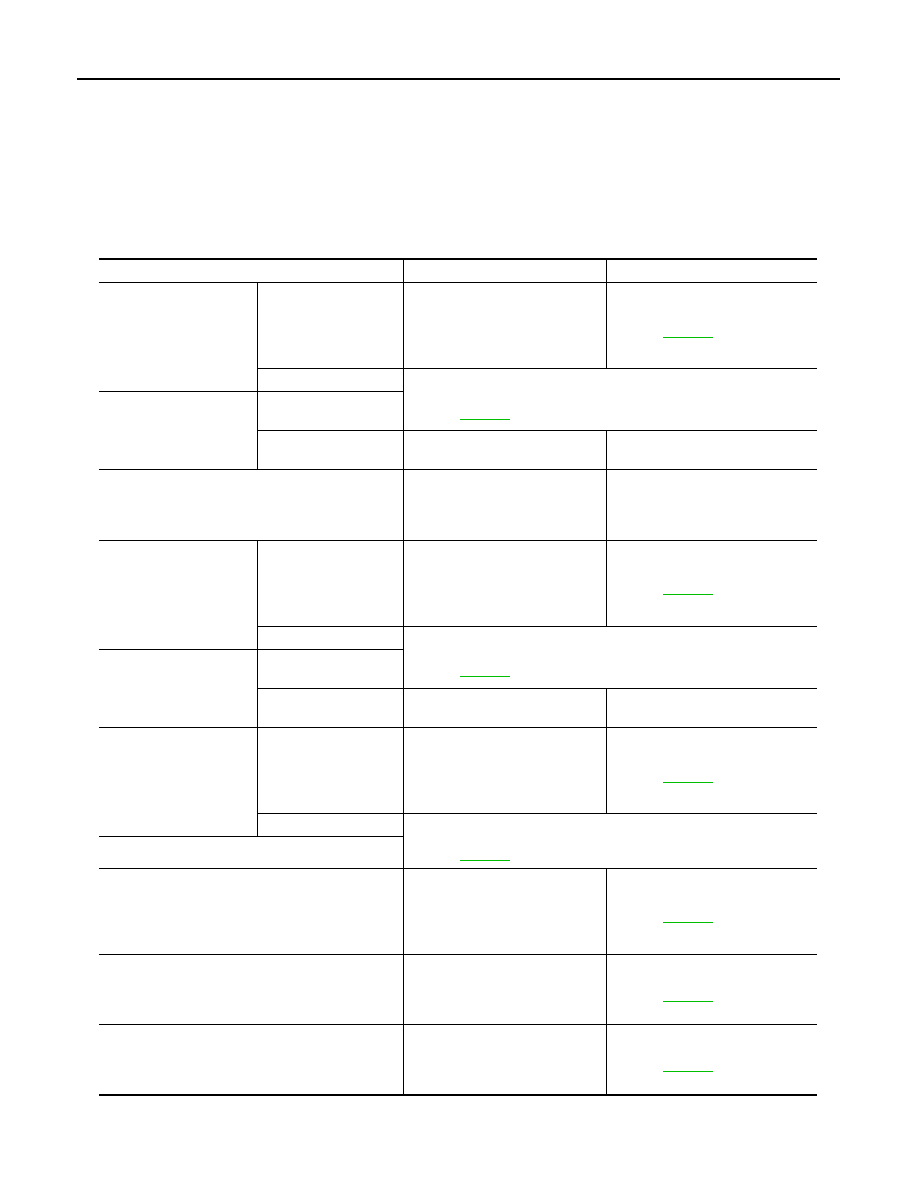

Symptom Table

INFOID:0000000003261469

CAUTION:

Perform the self-diagnosis with CONSULT-III before the symptom diagnosis. Perform the trouble diag-

nosis if any DTC is detected.

Symptom

Possible cause

Inspection item

Headlamp (HI) is not

turned ON.

One side

• Fuse

• Halogen bulb (HI)

• Harness between IPDM E/R

and the headlamp high

• IPDM E/R

Headlamp (HI) circuit

Refer to

Both sides

Symptom diagnosis

“BOTH SIDE HEADLAMPS (HI) ARE NOT TURNED ON”

Refer to

Headlamp (HI) is not

turned OFF.

When ignition switch is

turned ON.

When ignition switch is

turned OFF.

IPDM E/R

—

High beam indicator lamp is not turned ON.

[The headlamp (HI) is turned ON.]

Combination meter

• Combination meter

Data monitor “HI-BEAM IND”

• BCM (HEAD LAMP)

Active test “HEADLAMP”

Headlamp (LO) is not

turned ON.

One side

• Fuse

• Halogen bulb (LO)

• Harness between IPDM E/R

and the headlamp low

• IPDM E/R

Headlamp (LO) circuit

Refer to

Both sides

Symptom diagnosis

“BOTH SIDE HEADLAMPS (LO) ARE NOT TURNED ON”

Refer to

Headlamp (LO) is not

turned OFF.

When ignition switch is

turned ON.

When ignition switch is

turned OFF.

IPDM E/R

—

Front fog lamp is not

turned ON.

One side

• Front fog lamp bulb

• Harness between IPDM E/R

and the front fog lamp

• Front fog lamp

• IPDM E/R

Front fog lamp circuit

Refer to

Both sides

Symptom diagnosis

“BOTH SIDE FRONT FOG LAMPS ARE NOT TURNED ON”

Refer to

Front fog lamp is not turned ON.

Parking lamp is not turned ON.

• Parking lamp bulb

• Harness between IPDM E/R

and the front combination lamp

• Front combination lamp

• IPDM E/R

Parking lamp circuit

Refer to

Front side marker lamp is not turned ON.

• Front side marker lamp bulb

• Harness between IPDM E/R

and the front side marker lamp

• IPDM E/R

Front side marker lamp circuit

Refer to

Parking lamp and front side marker lamp are not

turned ON.

• Fuse

• Harness between IPDM E/R

and the front combination lamp

• IPDM E/R

Parking lamp circuit

Refer to

Revision: 2008 October

2009 Murano