Nissan Murano Z51 (2008 year). Manual - part 174

FUEL INJECTOR AND FUEL TUBE

EM-49

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

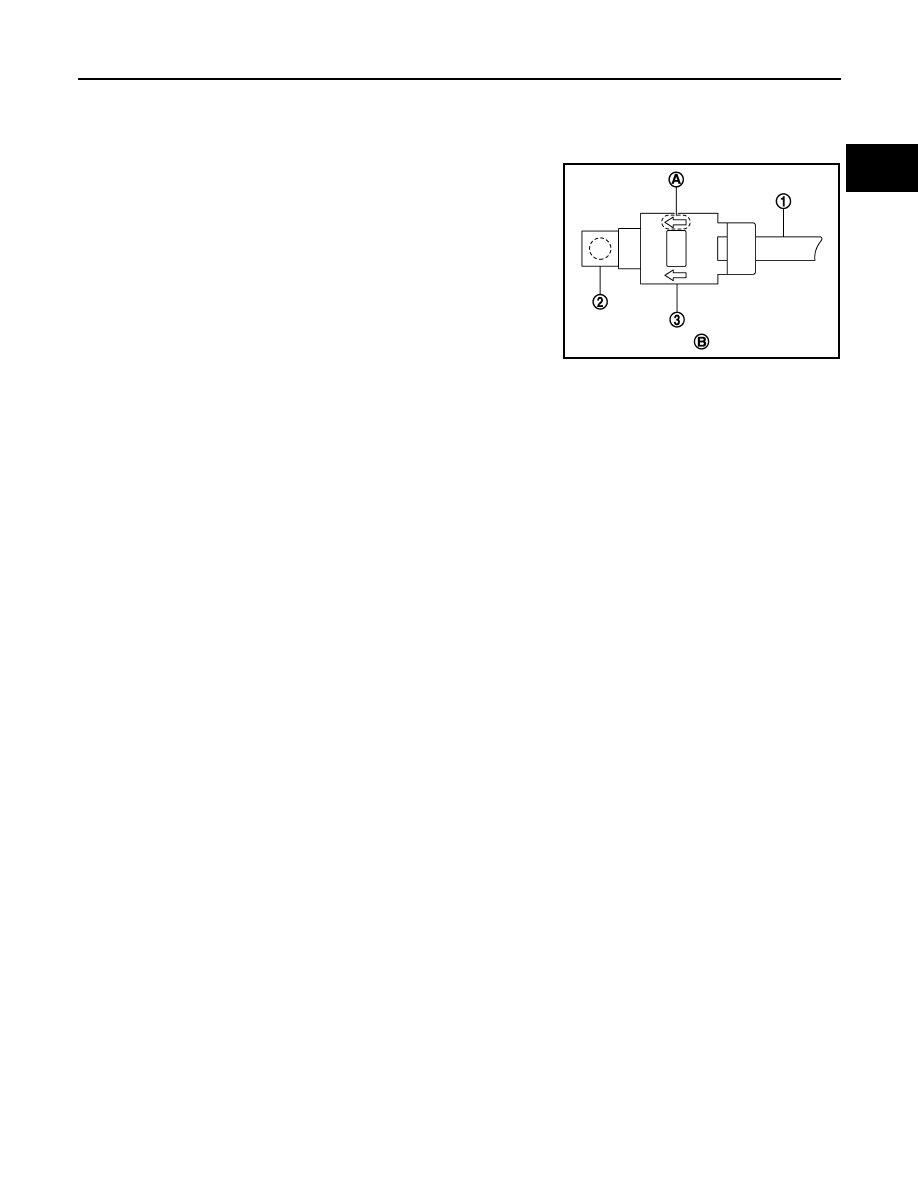

• Insert until you hear a “click” sound and actually feel the engagement.

• To avoid misidentification of engagement with a similar sound, be sure to perform the next step.

d.

Pull quick connector by hand holding position. Check it is completely engaged (connected) so that it does

not come out from fuel tube.

e.

Install quick connector cap (3) to quick connector.

• Install quick connector cap with arrow (A) on surface facing in

direction of quick connector (fuel feed hose side).

CAUTION:

If quick connector cap cannot be installed smoothly, quick

connector may have not been installed correctly. Check

connection again.

f.

Secure fuel feed hose to clamp of quick connector cap.

8.

Install in the reverse order of removal after this step.

Inspection

INFOID:0000000003304115

INSPECTION AFTER INSTALLATION

Check on Fuel Leakage

1.

Turn ignition switch “ON” (with the engine stopped). With fuel pressure applied to fuel piping, check there

are no fuel leakage at connection points.

NOTE:

Use mirrors for checking at points out of clear sight.

2.

Start the engine. With engine speed increased, check again that there are no fuel leakage at connection

points.

CAUTION:

Never touch the engine immediately after stopped, as the engine becomes extremely hot.

1

: Fuel feed hose

2

: Fuel tube

B

: Upper view

JPBIA0039ZZ

Revision: 2008 October

2009 Murano