Qashqai J11. Transaxle & Transmission - part 28

TM-434

< SYSTEM DESCRIPTION >

[CVT: RE0F10G]

COMPONENT PARTS

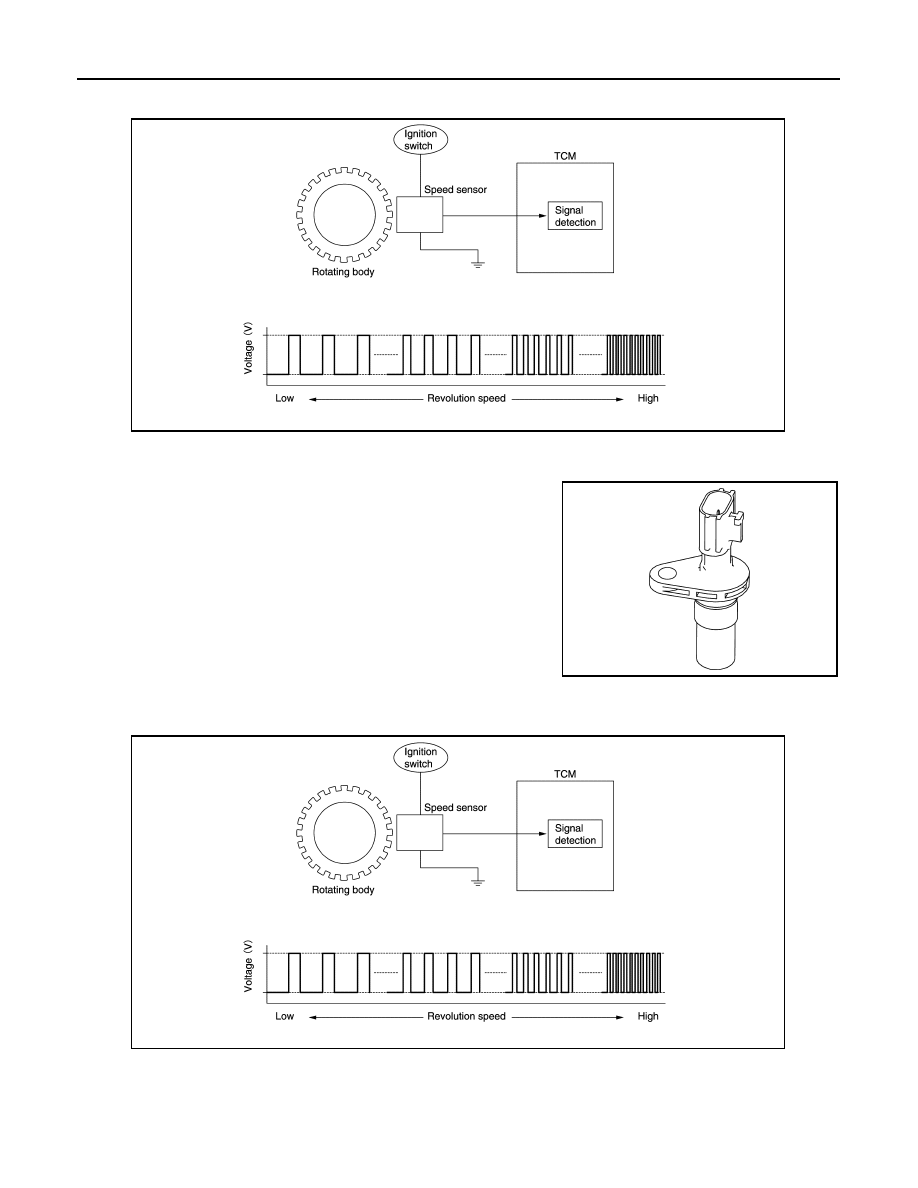

• The output speed sensor generates an ON-OFF pulse signal according to the rotating body speed. TCM

judges the rotating body speed from the pulse signal.

CVT CONTROL SYSTEM : Input Speed Sensor

INFOID:0000000010245523

• The input speed sensor is installed to the front side of transaxle

case.

• The input speed sensor detects input shaft speed.

• The input speed sensor generates an ON-OFF pulse signal according to the rotating body speed. TCM

judges the rotating body speed from the pulse signal.

CVT CONTROL SYSTEM : CVT Fluid Temperature Sensor

INFOID:0000000010245524

• The CVT fluid temperature sensor is installed to control valve.

• The CVT fluid temperature sensor detects CVT fluid temperature in oil pan.

JSDIA1824GB

JSDIA3074ZZ

JSDIA1824GB