Qashqai J11. Charging system - part 3

CHG

ALTERNATOR

CHG-31

< REMOVAL AND INSTALLATION >

[TYPE 1]

C

D

E

F

G

H

I

J

K

L

B

A

O

P

N

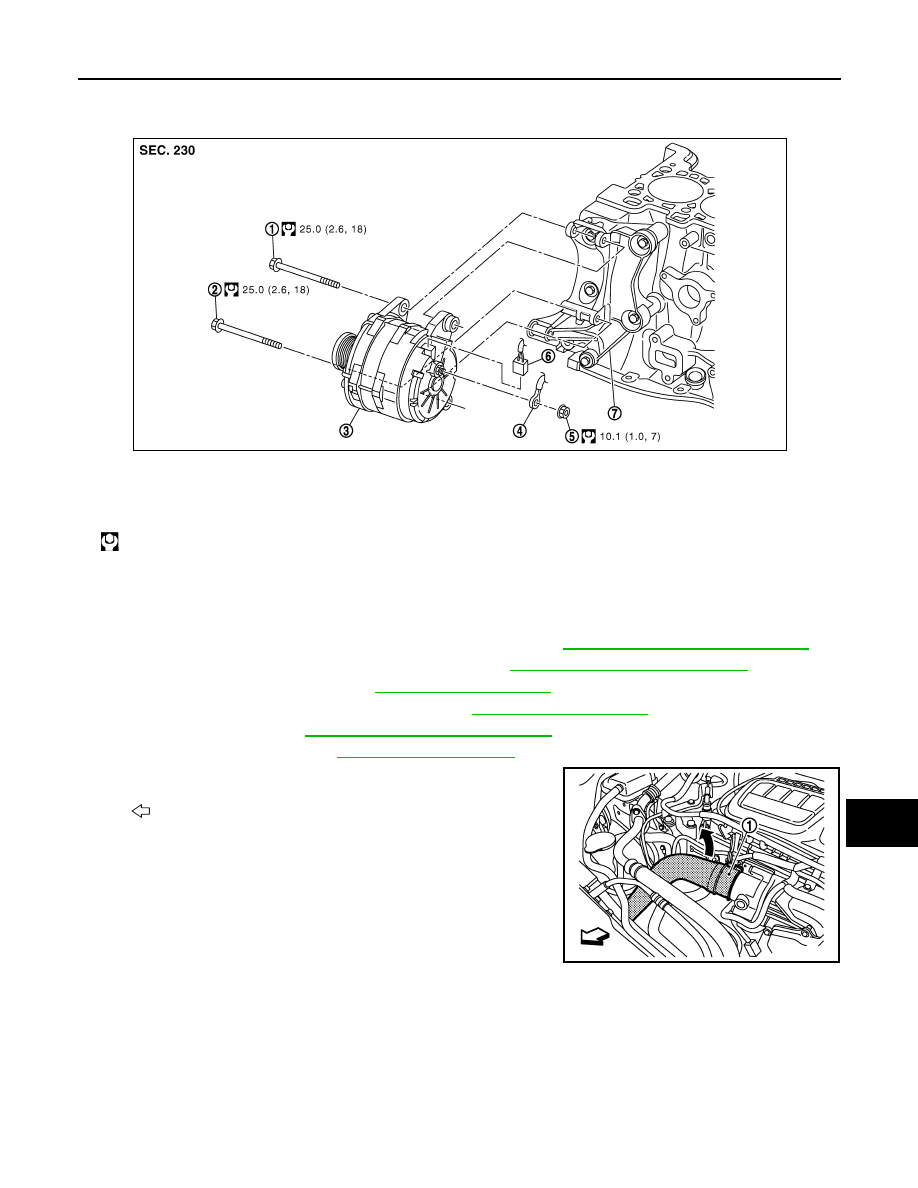

R9M : Exploded View

INFOID:0000000010323930

R9M : Removal and Installation

INFOID:0000000010323931

REMOVAL

1.

Disconnect the battery cable from the negative terminal. Refer to

PG-155, "Removal and Installation"

2.

Remove wheel nuts, and then tire assembly RH. Refer to

WT-60, "Removal and Installation"

.

3.

Remove engine under cover. Refer to

.

4.

Remove front fender protector RH partially. Refer to

.

5.

Remove drive belt. Refer to

EM-373, "Removal and Installation"

6.

Remove air duct (inlet). Refer to

.

7.

Get air inlet hose 1 (1) out of alternator removal area.

8.

Remove solenoid valve and bracket assembly.

1.

Alternator mounting bolt (upper)

2.

Alternator mounting bolt (lower)

3.

Alternator

4.

“B” terminal harness

5.

“B” terminal nut

6.

Alternator connector

7.

Alternator bracket

: N·m (kg-m, ft-lb)

JMMIA0962GB

: Vehicle front

JMMIA0963ZZ