Content .. 2260 2261 2262 2263 ..

Nissan Qashqai J11. Manual - part 2262

ENGINE MAINTENANCE (MR16DDT)

MA-83

< PERIODIC MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

• If necessary, refill radiator up to filler neck with engine coolant.

CAUTION:

Never adhere the engine coolant to electronic equipments (alternator etc.).

13. Refill reservoir tank to “MAX” level line with engine coolant.

14. Repeat steps 11 through 15 two or more times with radiator cap installed until engine coolant level no

longer drops.

15. Check cooling system for leakage with engine running.

16. Warm up the engine, and check for flowing noise while repeat at least three time slow acceleration from

idle up to 3,000 rpm.

17. If flowing noise is heard, bleed air from cooling system by repeating step 10 through 16 until flowing noise

is no longer heard.

ENGINE COOLANT : Flushing

INFOID:0000000011732686

1.

Turn ignition ON, wait for 10 seconds then turn ignition OFF.

2.

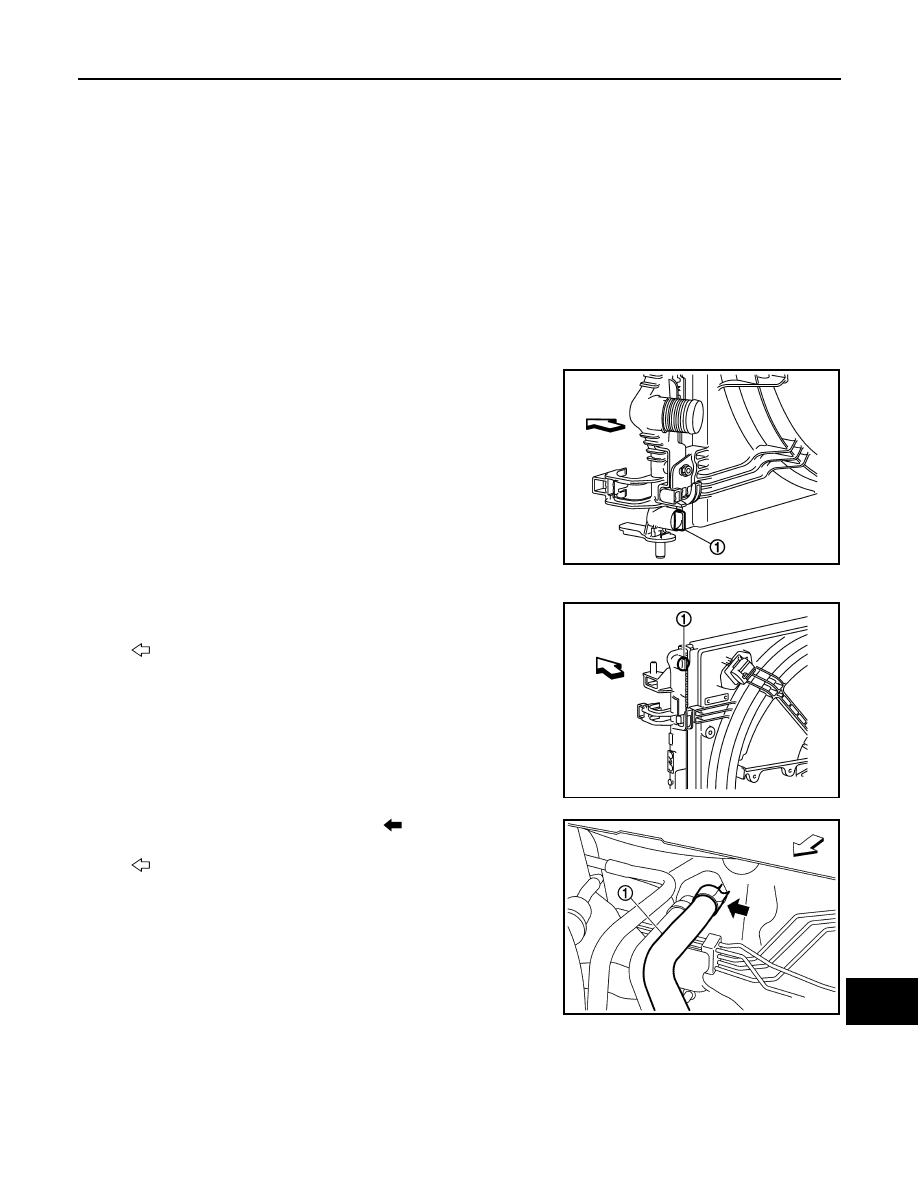

Install reservoir tank if removed and radiator drain plug (1).

CAUTION:

Be sure to clean drain plug and install with new O-ring.

3.

Open radiator air relief plug (1).

4.

Disconnect heater hose (1) at position (

) in the figure.

• Enhance heater as high as possible.

5.

Fill reservoir tank with water.

• When engine coolant over flows opened radiator air relief plug, close air relief plug, and continue filling

the engine coolant.

• When engine coolant over flows disconnected heater hose, connect heater hose, and continue filling the

engine coolant.

E1BIA1139ZZ

: Vehicle front

E1BIA1141ZZ

: Vehicle front

JPBIA4208ZZ