Nissan Juke F15. Manual - part 643

EM-126

< UNIT DISASSEMBLY AND ASSEMBLY >

[MR FOR NISMO RS MODELS]

CYLINDER BLOCK

Measure the outer diameter of piston pin with a micrometer (A).

Connecting Rod Bushing Oil Clearance

(Connecting rod bushing oil clearance) = (Connecting rod bushing inner diameter) – (Piston pin outer diame-

ter)

• If the measured value is out of the standard, replace connecting rod assembly and/or piston and piston pin

assembly.

• If replacing piston and piston pin assembly. Refer to

.

• If replacing connecting rod assembly. Refer to

EM-134, "Connecting Rod Bearing"

.

CYLINDER BLOCK TOP SURFACE DISTORTION

• Using a scraper, remove gasket on the cylinder block surface, and also remove engine oil, scale, carbon, or

other contamination.

CAUTION:

Be careful not to allow gasket flakes to enter engine oil or engine coolant passages.

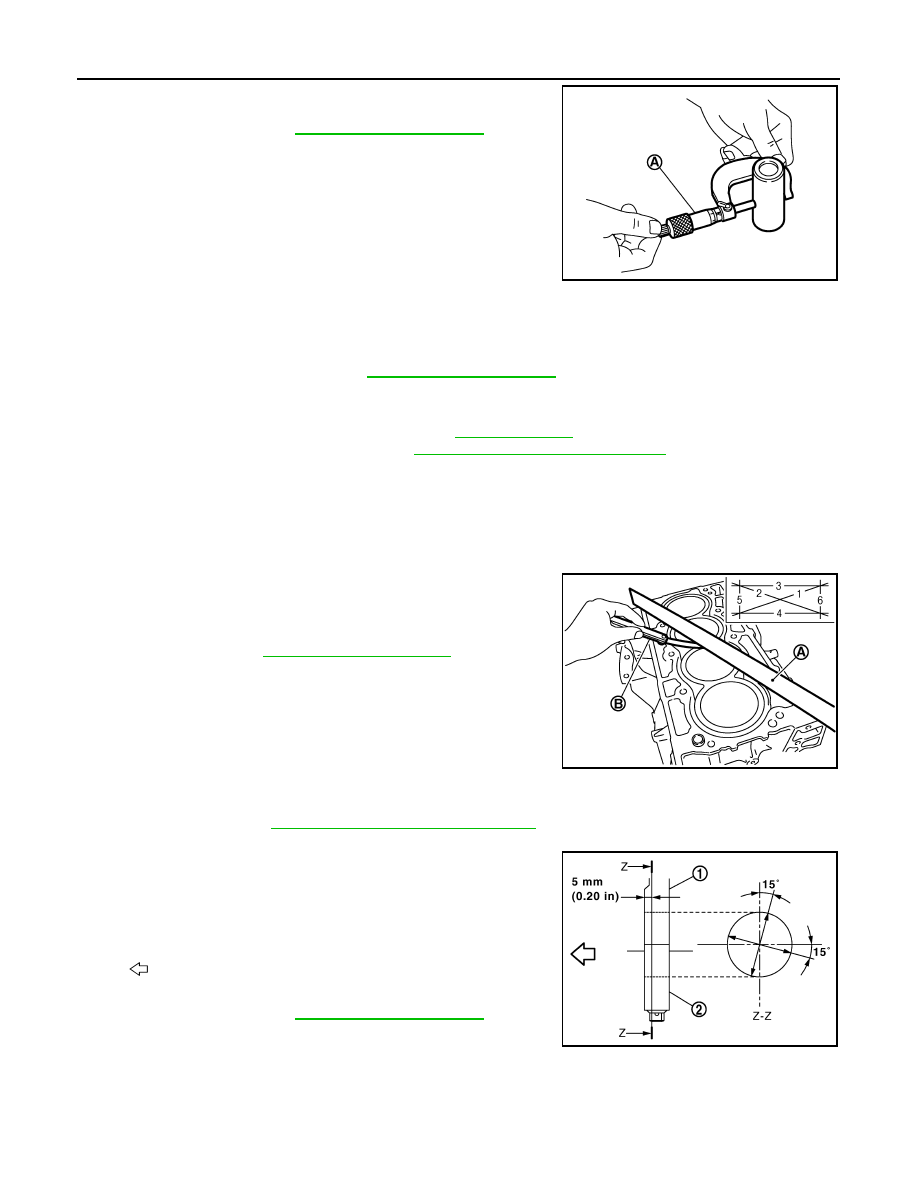

• Measure the distortion on the cylinder block upper face at some

different points in six directions with a straight edge (A) and feeler

gauge (B).

• If it exceeds the limit, replace cylinder block.

MAIN BEARING HOUSING INNER DIAMETER

• Install main bearing cap without main bearings installed, and tighten main bearing cap mounting bolts to the

specified torque. Refer to

EM-115, "Disassembly and Assembly"

.

• Measure the inner diameter of main bearing housing with a bore gauge.

• Measure the position shown in the figure [5 mm (0.20 in)] back-

ward from main bearing housing front side in the 2 directions as

shown in the figure. The smaller one is the measured value.

• If out of the standard, replace cylinder block and main bearing

caps assembly.

NOTE:

Main bearing caps cannot be replaced as a single, because it is machined together with cylinder block.

PISTON TO CYLINDER BORE CLEARANCE

Standard :

PBIC3266J

Standard and Limit

: Refer to

Limit :

Refer

.

PBIC3250J

1

: Cylinder block

2

: Main bearing cap

: Engine front

Standard :

PBIC4005E