Nissan Juke F15. Manual - part 637

EM-102

< UNIT DISASSEMBLY AND ASSEMBLY >

[MR FOR NISMO RS MODELS]

CYLINDER HEAD

• Camshaft: Refer to

.

2. Remove cylinder head.

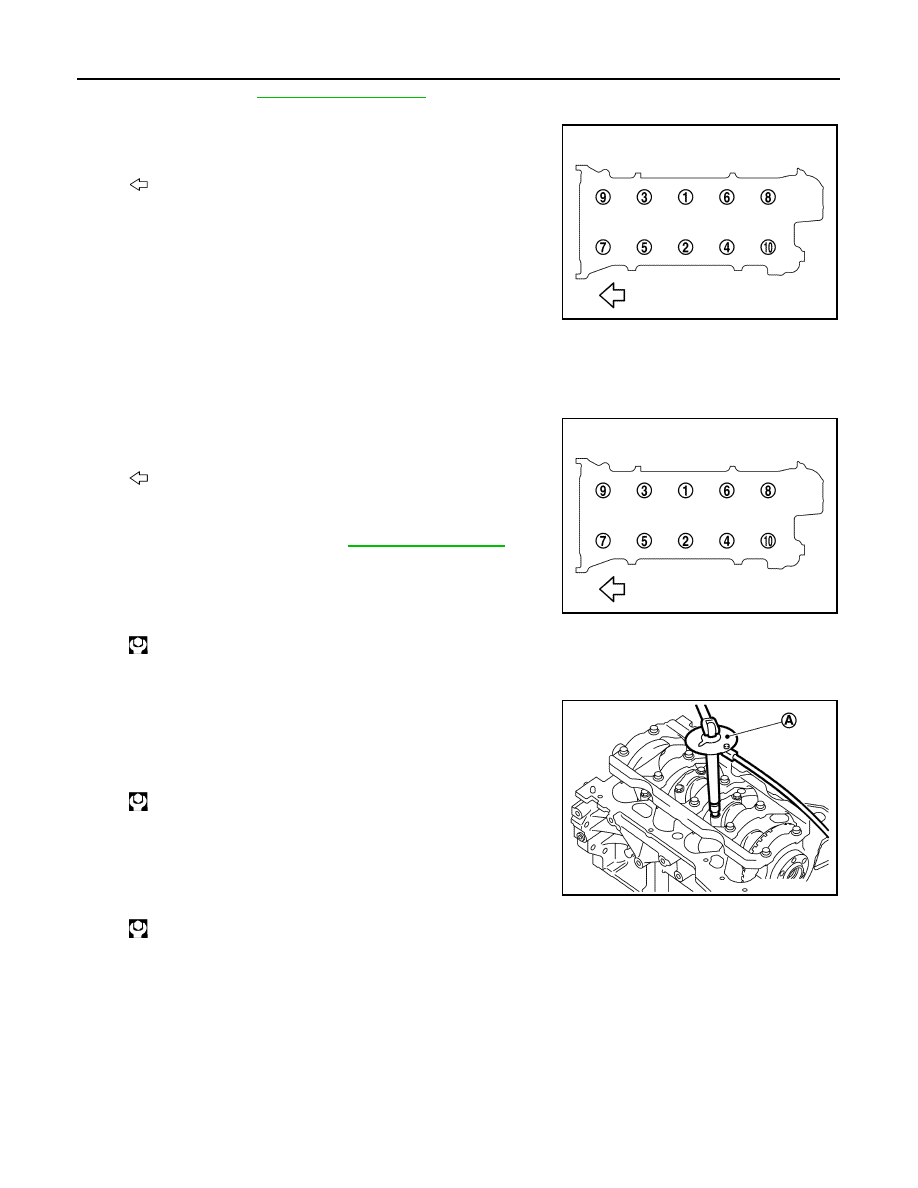

• Loosen cylinder head bolts in reverse order as shown in the

figure.

• Using TORX socket, loosen cylinder head bolts.

3. Remove cylinder head gasket.

INSTALLATION

1. Install cylinder head gasket.

2. Install cylinder head, and tighten cylinder head bolts in numeri-

cal order as shown in the figure with the following procedure.

CAUTION:

If cylinder head bolts are reused, check their outer diame-

ters before installation. Refer to

.

a. Apply new engine oil to threads and seating surface of mounting

bolts.

b. Tighten all cylinder head bolts.

c.

Turn all cylinder head bolts 100 degrees clockwise (angle tightening).

CAUTION:

Check and confirm the tightening angle by using an angle

wrench [SST: KV10112100 (BT8653-A)] (A) or protractor.

Never judge by visual inspection without the tool.

d. Completely loosen.

CAUTION:

In this step, loosen cylinder head bolts in reverse order that

indicated in the figure.

e. Tighten all cylinder head bolts.

f.

Turn all cylinder head bolts 95 degrees clockwise (angle tightening).

g. Turn all cylinder head bolts 95 degrees clockwise again (angle tightening).

3. Install in the reverse order of removal, for the rest of parts.

Disassembly and Assembly

INFOID:0000000012197304

DISASSEMBLY

1. Remove spark plug with spark plug wrench (commercial service tool).

2. Remove valve lifter.

• Identify installation positions, and store them without mixing them up.

: Engine front

JPBIA4415ZZ

: Engine front

: 40.0 N·m (4.1 kg-m, 30 ft-lb)

: 0 N·m (0 kg-m, 0 ft-lb)

: 40.0 N·m (4.1 kg-m, 30 ft-lb)

JPBIA4415ZZ

JPBIA4435ZZ