Nissan Juke F15. Manual - part 577

P159C, P159D G SENSOR

EC-1121

< DTC/CIRCUIT DIAGNOSIS >

[MR EXCEPT FOR NISMO RS MODELS]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

2.

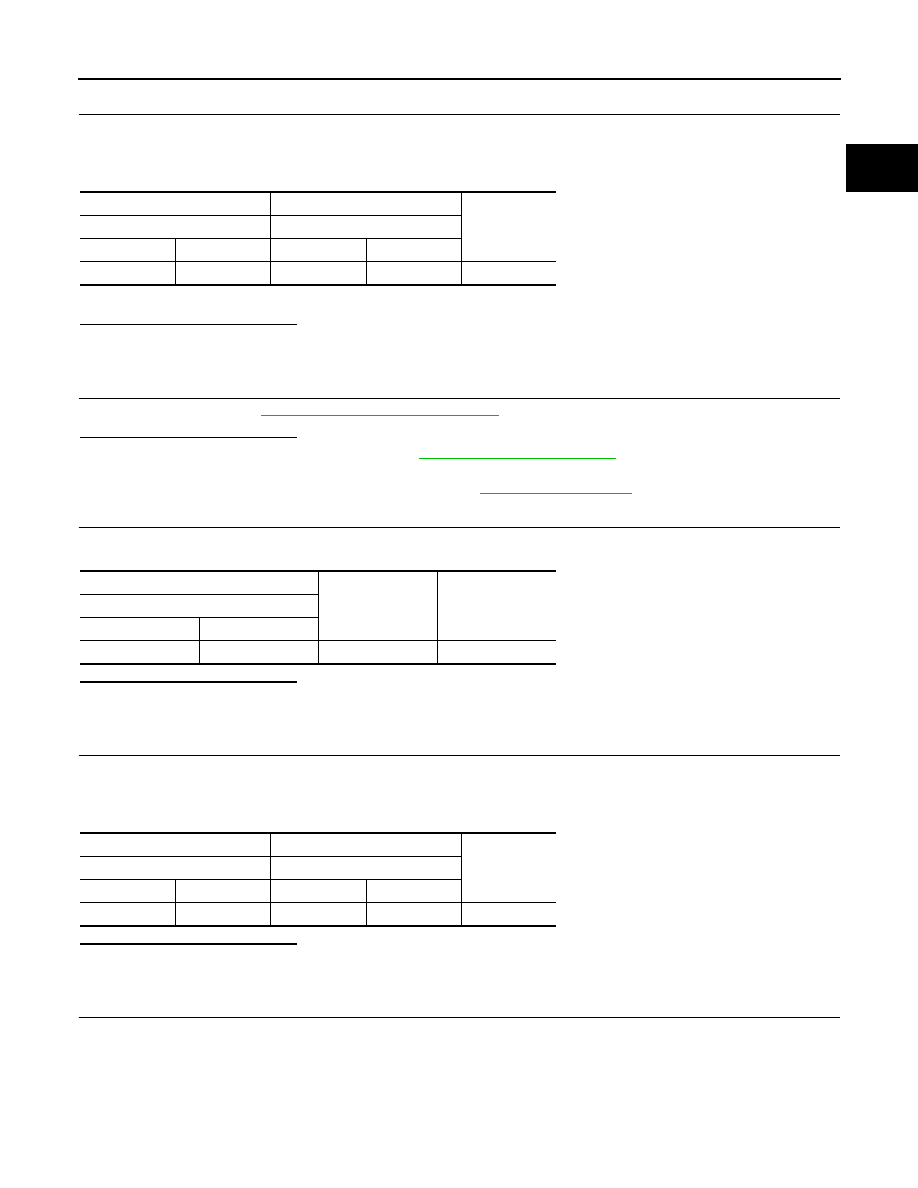

CHECK G SENSOR SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between G sensor harness connector and ECM harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair or replace error-detected parts.

3.

CHECK G SENSOR

Check G sensor. Refer to

EC-1122, "Component Inspection"

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-45, "Intermittent Incident"

.

NO

>> 1. Replace G sensor.

2. Perform calibration of G sensor. Refer to

4.

CHECK G SENSOR POWER SUPPLY CIRCUIT-II

Check the voltage between G sensor harness connector terminal and ground.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> GO TO 7.

5.

CHECK G SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between G sensor harness connector and ECM harness connector.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Repair or replace error-detected parts.

6.

CHECK ECM GROUND CIRCUIT

Check the continuity between ECM harness connector and ground.

+

−

Continuity

G sensor

ECM

Connector

Terminal

Connector

Terminal

B32

1

F23

34

Existed

+

−

Voltage

(Approx.)

G sensor

Connector

Terminal

B32

3

Ground

5 V

+

−

Continuity

G sensor

ECM

Connector

Terminal

Connector

Terminal

B32

3

F23

29

Existed