Nissan Juke F15. Manual - part 451

COMPONENT PARTS

EC-617

< SYSTEM DESCRIPTION >

[MR EXCEPT FOR NISMO RS MODELS]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

<Reference data>

*: These data are reference values and are measured between ECM terminals.

Cooling Fan

INFOID:0000000012198181

COOLING FAN CONTROL MODULE

Cooling fan control module receives ON/OFF pulse duty signal from IPDM E/R. Corresponding to this ON/OFF

pulse duty signal, cooling fan control module sends cooling fan motor operating voltage to cooling fan motor.

The revolution speed of cooling fan motor is controlled by duty cycle of the voltage.

COOLING FAN MOTOR

Cooling fan motor receives cooling fan motor operating voltage from cooling fan control module. The revolu-

tion speed of cooling fan motor is controlled by duty cycle of the voltage.

EVAP Canister Purge Volume Control Solenoid Valve

INFOID:0000000012198182

The EVAP canister purge volume control solenoid valve uses a ON/

OFF duty to control the flow rate of fuel vapor from the EVAP canis-

ter. The EVAP canister purge volume control solenoid valve is

moved by ON/OFF pulses from the ECM. The longer the ON pulse,

the greater the amount of fuel vapor that will flow through the valve.

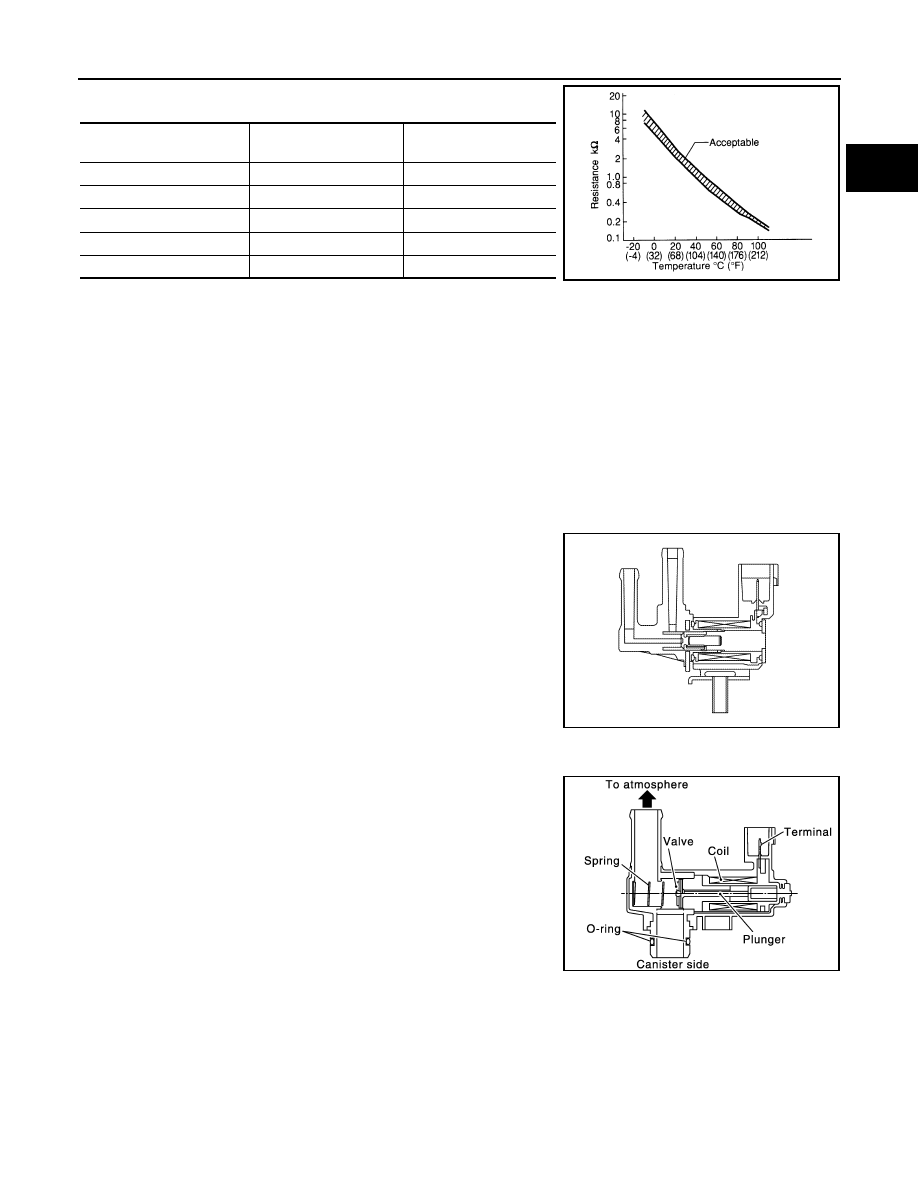

EVAP Canister Vent Control Valve

INFOID:0000000012198183

The EVAP canister vent control valve is located on the EVAP canis-

ter and is used to seal the canister vent.

This solenoid valve responds to signals from the ECM. When the

ECM sends an ON signal, the coil in the solenoid valve is energized.

A plunger will then move to seal the canister vent. The ability to seal

the vent is necessary for the on board diagnosis of other evaporative

emission control system components.

This solenoid valve is used only for diagnosis, and usually remains

opened.

When the vent is closed, under normal purge conditions, the evapo-

rative emission control system is depressurized and allows “EVAP

Control System” diagnosis.

Engine oil temperature

[

°C (°F)]

Voltage

*

(V)

Resistance (k

Ω)

–10 (14)

4.29-4.50

7.0 - 11.4

20 (68)

3.48-3.58

2.37 - 2.63

50 (122)

2.03-2.49

0.68 - 1.00

90 (194)

0.97-1.04

0.236 - 0.260

110 (230)

0.63-0.67

0.143 - 0.153

SEF012P

JSBIA0651ZZ

PBIB1263E