Content .. 1324 1325 1326 1327 ..

Nissan Juke F15. Manual - part 1326

TM-494

< DTC/CIRCUIT DIAGNOSIS >

[CVT: RE0F10D]

P0826 UP AND DOWN SHIFT SW

NO

>> Repair or replace damaged parts.

7.

CHECK GROUND CIRCUIT

Check continuity between CVT shift selector harness connector terminal and ground.

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-45, "Intermittent Incident"

.

NO

>> Repair or replace damaged parts.

8.

CHECK PADDLE SHIFTER

1. Turn ignition switch OFF.

2. Disconnect paddle shifter connector.

3. Turn ignition switch ON.

4. Check voltage between paddle shifter side harness connector terminals.

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> GO TO 11.

9.

CHECK PADDLE SHIFTER

Check paddle shifter. Refer to

TM-496, "Component Inspection (Paddle Shifter)"

.

Is the inspection result normal?

YES

>> GO TO 10.

NO

>> Repair or replace damaged parts.

10.

CHECK GROUND CIRCUIT

Check continuity between paddle shifter vehicle side harness connector terminal and ground.

Is the inspection result normal?

YES

>> GO TO 11.

NO

>> Repair or replace damaged parts.

11.

CHECK POWER SOURCE CIRCUIT

Check voltage between paddle shifter vehicle side harness connector terminal and ground.

Is the inspection result normal?

YES

>> GO TO 12.

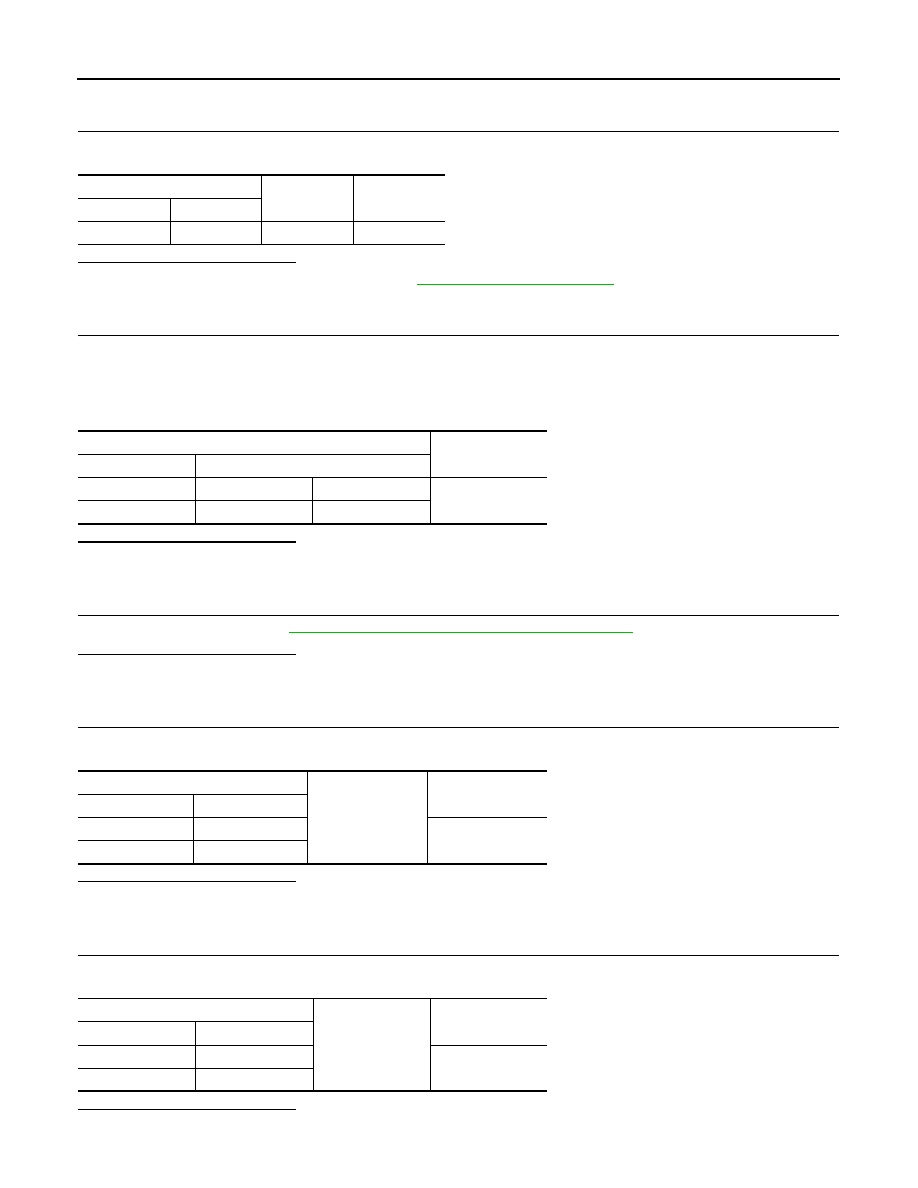

CVT shift selector

—

Continuity

Connector

Terminal

M57

10

Ground

Existed

Paddle shifter

Voltage (Approx.)

Connector

Terminal

M96

3

1

Battery voltage

M97

3

1

Paddle shifter

Ground

Continuity

Connector

Terminal

M96

1

Existed

M97

1

Paddle shifter

Ground

Voltage (Approx.)

Connector

Terminal

M96

3

0 V

M97

3