Content .. 1225 1226 1227 1228 ..

Nissan Juke F15. Manual - part 1227

TM-98

< UNIT DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F52H]

TRANSAXLE ASSEMBLY

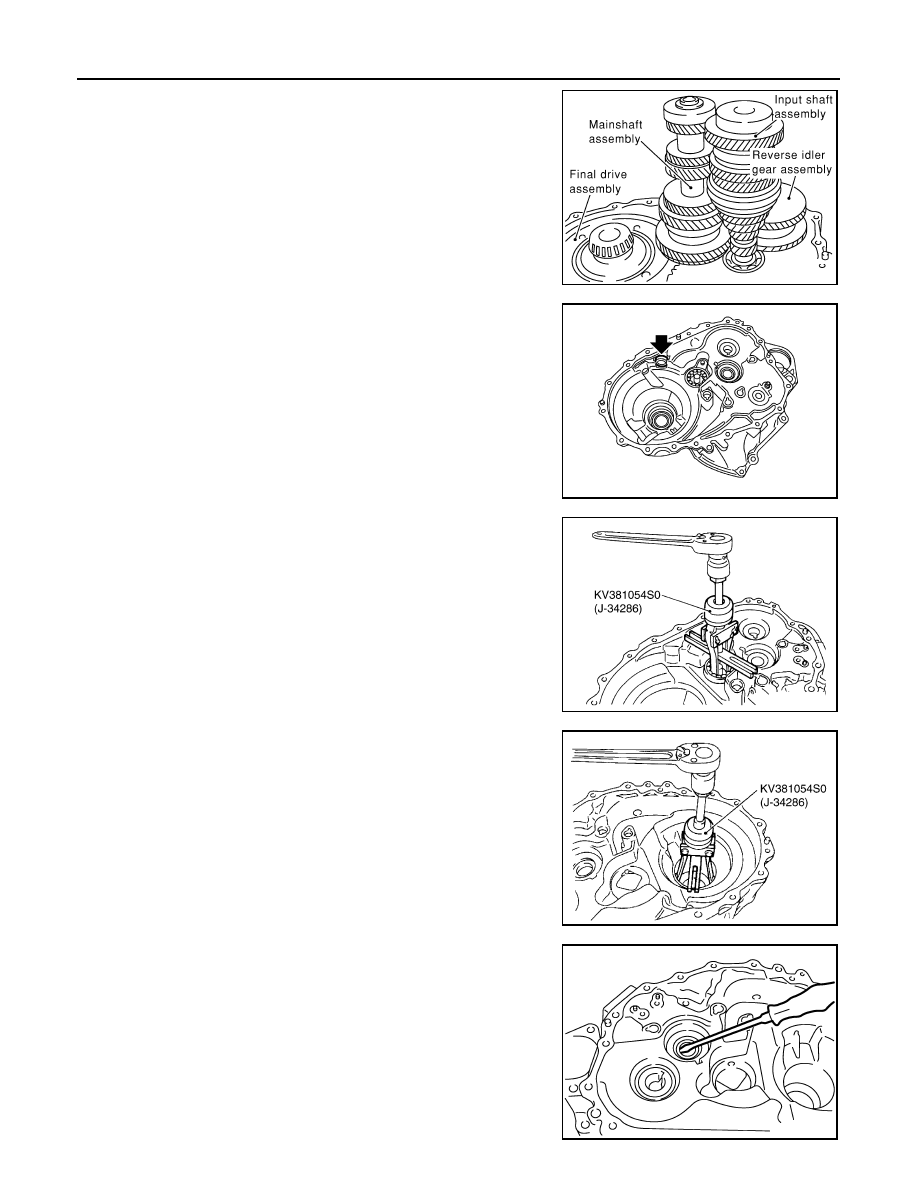

30. Remove gear components from clutch housing in the following

procedure.

a. Remove a set of input shaft assembly, mainshaft assembly, and

reverse idler gear assembly by tapping the tip of input shaft from

the back of the clutch housing with a plastic hammer.

CAUTION:

Always withdraw mainshaft straight out. Failure to do so

can damage resin oil channel on clutch housing side.

b. Remove final drive assembly.

31. Remove magnet from clutch housing.

32. Remove mainshaft bearing retainer and then mainshaft front

bearing from clutch housing using the Tool.

CAUTION:

Do not damage clutch housing, mainshaft front bearing, or

oil channel.

33. Remove oil channel from clutch housing.

34. Remove differential side bearing outer race (clutch housing

side) from clutch housing using the puller.

CAUTION:

Do not damage clutch housing or differential side bearing

outer race.

35. Remove input shaft oil seal from clutch housing, using a suitable

tool.

CAUTION:

Do not damage clutch housing.

SCIA0964E

PCIB1859E

Tool number

: KV381054S0 (J-34286)

PCIB0937E

Tool number

: KV381054S0 (J-34286)

PCIB0938E

SCIA0398E