Content .. 1704 1705 1706 1707 ..

Mitsubishi Outlander GS45X. Manual - part 1706

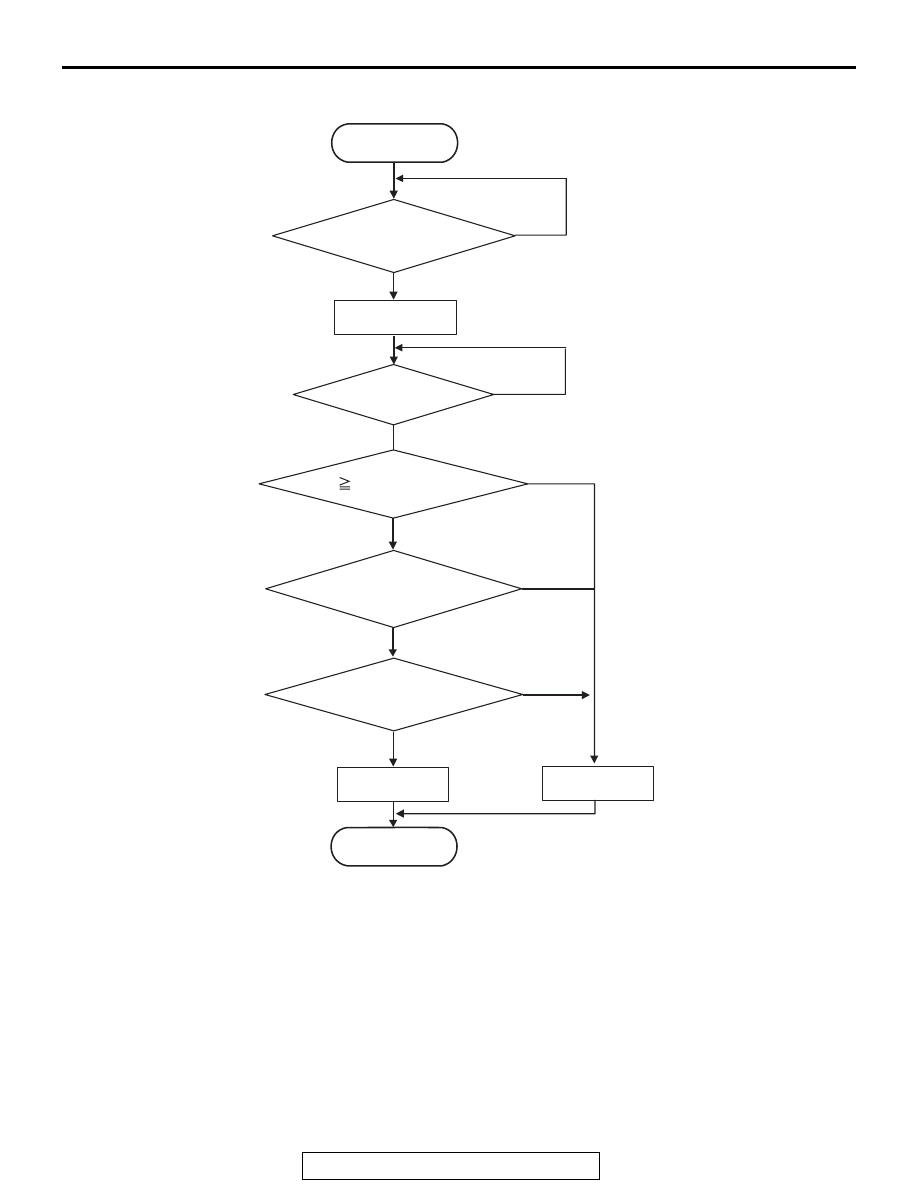

AUTOMATIC TRANSAXLE DIAGNOSIS <A/T>

TSB Revision

AUTOMATIC TRANSAXLE

23C-129

LOGIC FLOW CHARTS (Monitor Sequence)

.

DTC SET CONDITIONS

Check Conditions

• TCM is started: more than 1.05 seconds.

• Vehicle speed: more than 55 km/h (34.4 mph).

Judgement Criteria

• ABS status signal: fail. (0.5 second)

.

OBD-II DRIVE CYCLE PATTERN

Drive with the vehicle speed 5 km/h or more for 5

seconds or more.

.

TROUBLESHOOTING HINTS (THE MOST

LIKELY CAUSES FOR THIS CODE TO BE

SET ARE:)

• Malfunction of the CAN

• Malfunction of the ABS/ASC-ECU

Good

END

START

Yes

No

No

Yes

No

Yes

Yes

No

TCM is started

ABS error signal

reception

Continuous failure

for 500 msecs.

Timer start

Timer > 1.05 secs.

Malfunction

Yes

No

AC802682

Voss: Calculated vehicle speed

by output shaft speed sensor

Voss 55 km/h (34.4 mph)