Mitsubishi Montero (1998+). Manual - part 95

Fig. 7: Measuring Ring Gear Runout

Courtesy of Mitsubishi Motor Sales of America.

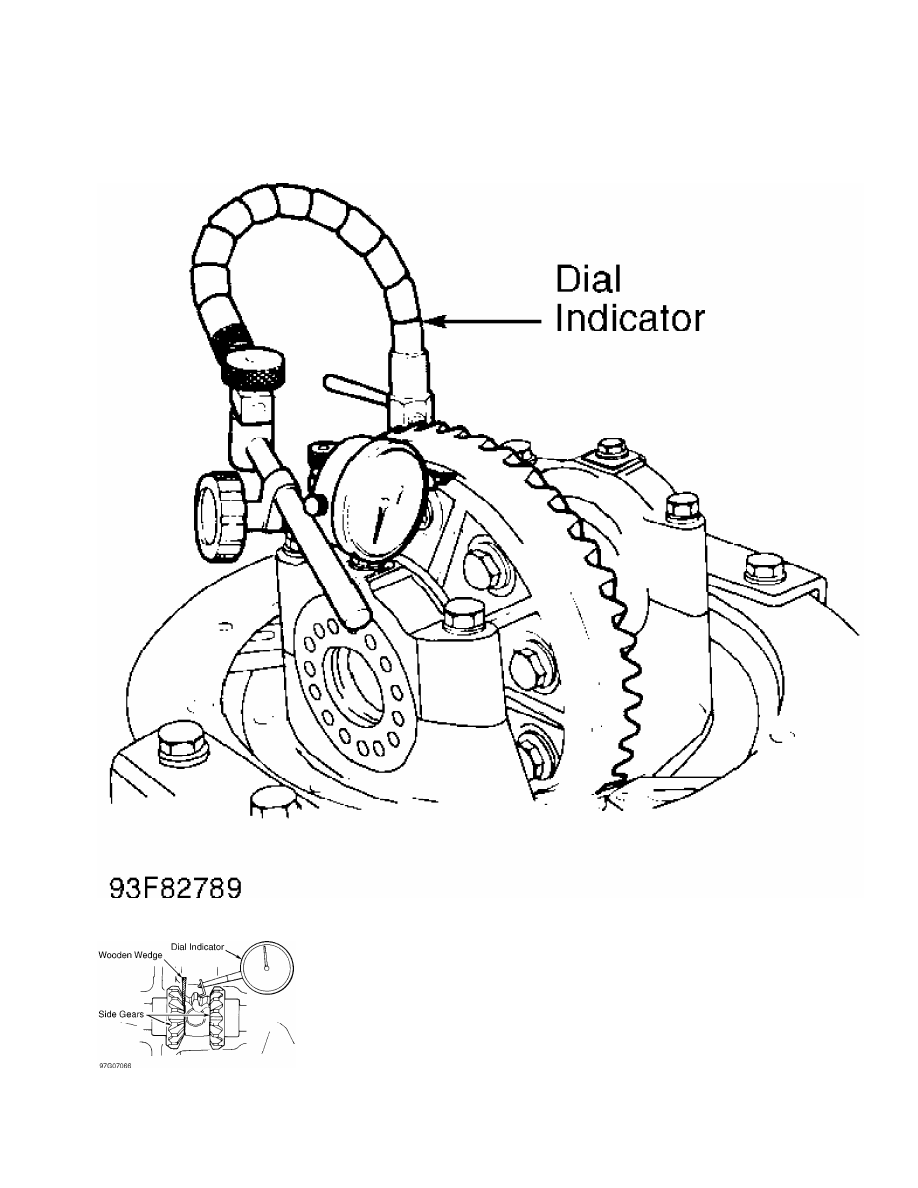

Fig. 8: Checking Pinion & Side Gear Backlash

Courtesy of Mitsubishi Motor Sales of America.

NOTE: See DIFFERENTIAL ASSEMBLY (LIMITED SLIP) for carrier