Mitsubishi Galant 9G. Manual - part 467

EMISSION CONTROL

TSB Revision

ENGINE AND EMISSION CONTROL

17-86

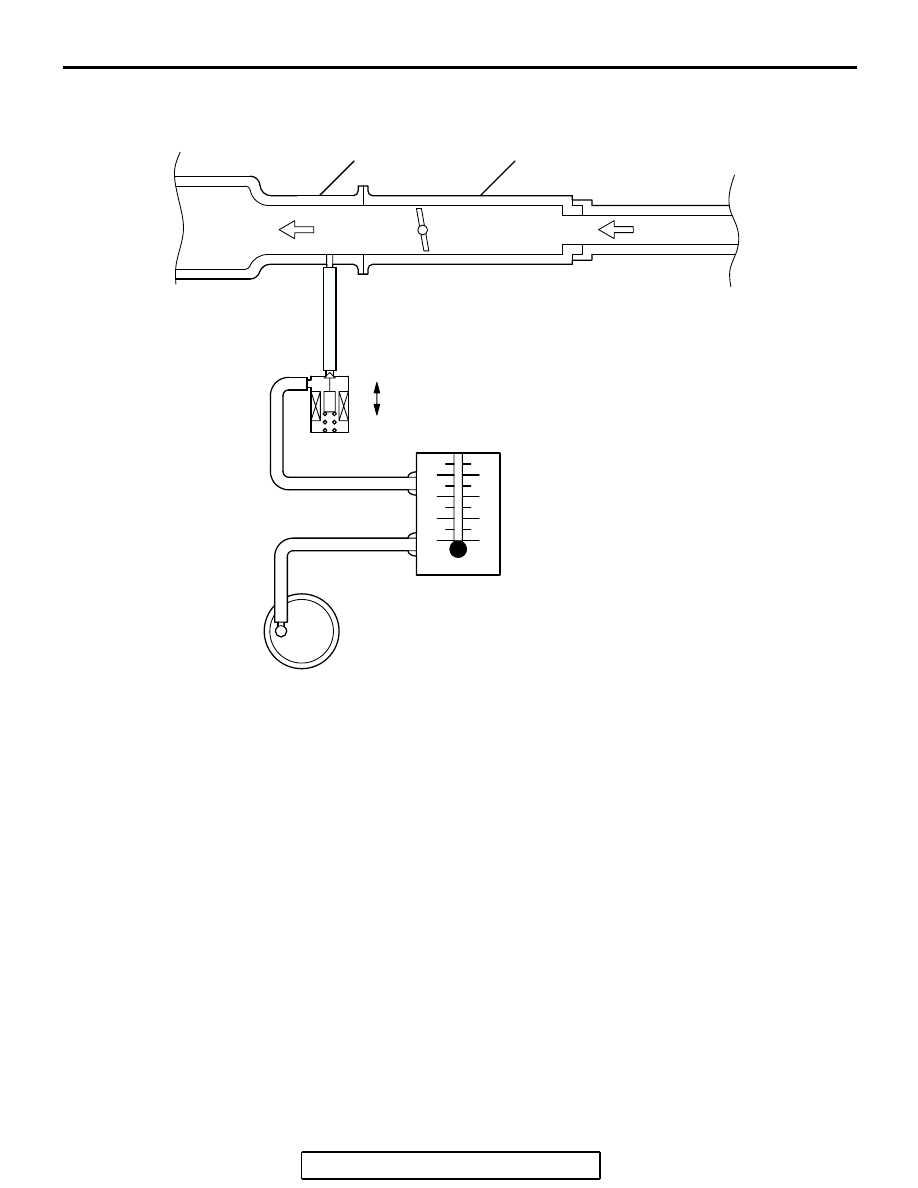

PURGE CONTROL SYSTEM CHECK (PURGE FLOW CHECK)

M1173001400620

Required Special Tool:

MB995061: Purge Flow Indicator

1. Disconnect the purge hose from the evaporative emission

(EVAP) purge solenoid, and connect special tool MB995061

between the EVAP purge solenoid and the purge hose.

2. Before inspection, set the vehicle in the following conditions:

• Engine coolant temperature: 80 − 95°C (176 − 203°F)

• Lights, electric cooling fan and accessories: OFF

• Transaxle: P range

NOTE: Vehicles for Canada, the headlight, taillight, etc.

remain lit even when the lighting switch is in "OFF" position

but this is no problem for checks.

3. Run the engine at idle for more than four minutes.

4. Check the purge flow volume when engine is revved

suddenly several times.

Standard value: Momentarily 20 cm

3

/s (2.5 SCFH) or

more.

AK300556

THROTTLE BODY

INTAKE MANIFOLD

FROM

AIR CLEANER

TO

COMBUSTION

CHAMBER

AB

OFF

ON

EVAPORATIVE EMISSION

PURGE SOLENOID

(ON: OPENED)

PURGE

FLOW

INDICATOR

(MB995061)

PURGE HOSE

EVAPORATIVE EMISSION

CANISTER