Mitsubishi Lancer. Manual - part 252

STRUT ASSEMBLY

FRONT SUSPENSION

33-10

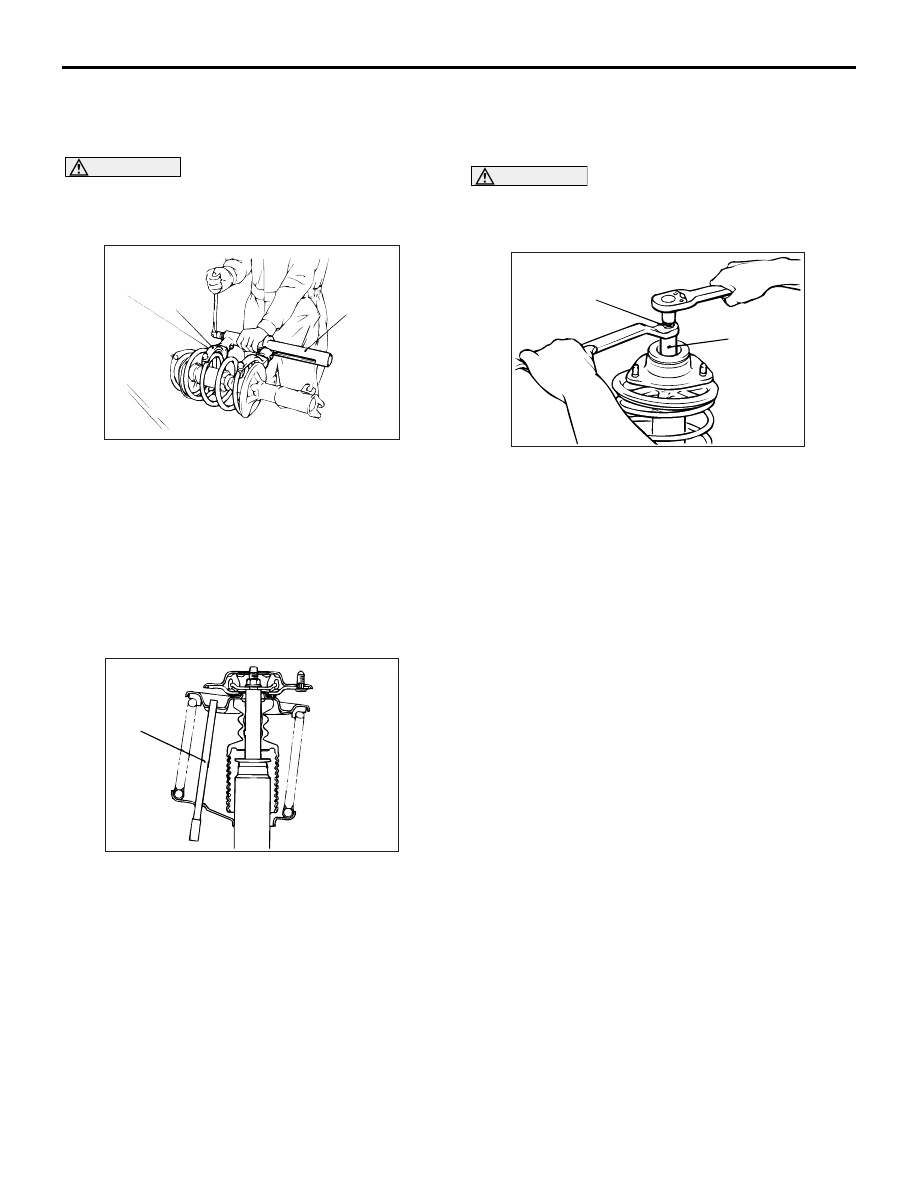

>>B<< STRUT NUT (SELF-LOCKING NUT)

INSTALLATION

1. Ensure that the bearing is seated correctly.

CAUTION

Do not use an impact wrench to tighten the bolt

of special tool spring compressor body

(MB991237), otherwise the special tool will break.

AC001085 AB

MB991238

MB991237

2. Install following special tools to the strut assembly

same as its removal.

• Spring compressor body (MB991237)

• Arm set (MB991238)

3. While the coil spring is being compressed by the

special tools, temporarily tighten the strut nut

(self-locking nut).

4. Align the hole in the strut spring lower seat with

the hole in the spring upper seat.

NOTE:

AC006091 AB

Rod

Using a rod as shown facilitates the alignment.

5. Align lower end of the coil spring with the groove

in the spring lower seat, and then loosen the

special tools.

CAUTION

Do not use an impact wrench to tighten the

self-locking nut, otherwise the strut nut

(self-locking nut) will be damaged.

AC006091 AB

MB991681

MB991682

6. Using following special tools, tighten the strut nut

(self-locking nut) to 60

± 10 N⋅ m.

• Wrench (MB991681)

• Socket (MB991682)

INSPECTION

M1332001400188

• Check the strut bearing for wear or rust.

• Check the rubber parts for damage or deteriora-

tion.

• Check the coil spring for deformation, deteriora-

tion or damage.

• Check the strut for deformation.