Mitsubishi Lancer. Manual - part 217

EMISSION CONTROL <MPI>

ENGINE AND EMISSION CONTROL

17-16

5. Replace the gasket, and tighten to the specified

torque.

Tightening torque:

<4G1> 21

± 4 N⋅ m

<4G6> 20

± 2 N⋅ m

EGR PORT VACUUM CHECK <4G1>

M1173002900167

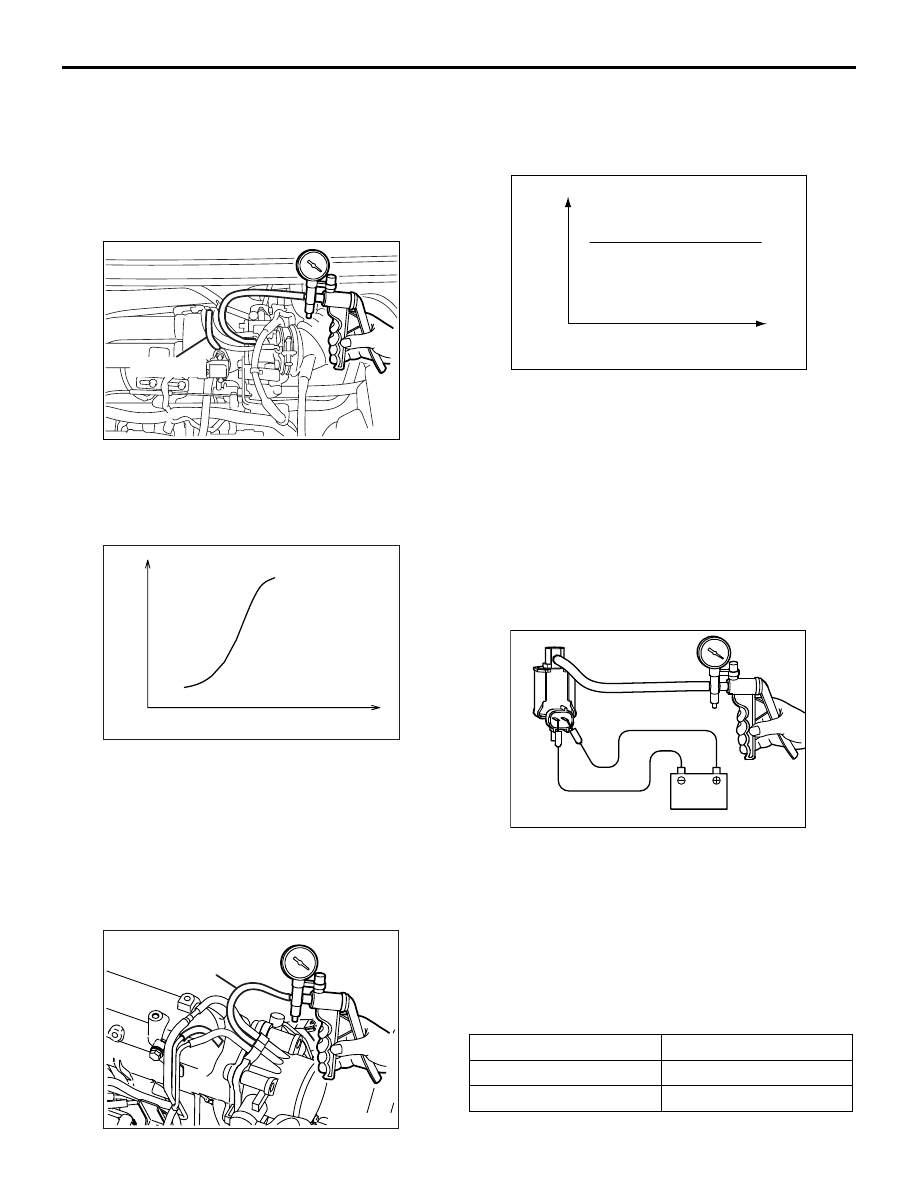

AK300784AB

Green strip

1. Disconnect the vacuum hose (Green stripe) from

the throttle body EGR vacuum nipple and connect

a hand vacuum pump to the nipple.

2. Plug the vacuum hose (Green stripe).

AK201224AB

Vac-

uum

Engine speed (r/min)

3. Start the engine and check that, after raising the

engine speed by racing the engine, purge vacuum

raises according to engine speed.

NOTE: If there is a problem with change in vac-

uum, the throttle body purge port may be clogged

and require cleaning.

EGR PORT VACUUM CHECK <4G6>

M1173002900156

AK300786AB

White stripe

1. Disconnect the vacuum hose (White stripe) from

the throttle body EGR vacuum nipple and connect

a hand vacuum pump to the nipple.

2. Plug the vacuum hose (White stripe).

AK100011

AC

Vac-

uum

Engine speed (r/min)

3. Start the engine.

4. Check that a fairly constant negative is generated

regardless of the engine speed.

5. If no negative pressure is generated, the port is

probably blocked and should be cleaned.

EGR CONTROL SOLENOID VALVE

CHECK <4G1>

M1173003100238

NOTE: When disconnecting the vacuum hose,

always make a mark so that it can be reconnected at

original position.

AKX00351

A

B

AE

Battery

1. Disconnect the vacuum hose from the solenoid

valve.

2. Disconnect the harness connector.

3. Connect a hand vacuum pump to nipple (A) of the

solenoid valve (refer to the illustration at left).

4. Check air tightness by applying a vacuum with

voltage applied directly from the battery to the

EGR control solenoid valve and without applying

voltage.

Battery voltage

Normal condition

Applied

Vacuum leaks

Not applied

Vacuum maintained