Mitsubishi Evolution X. Manual - part 824

AC201323 AD

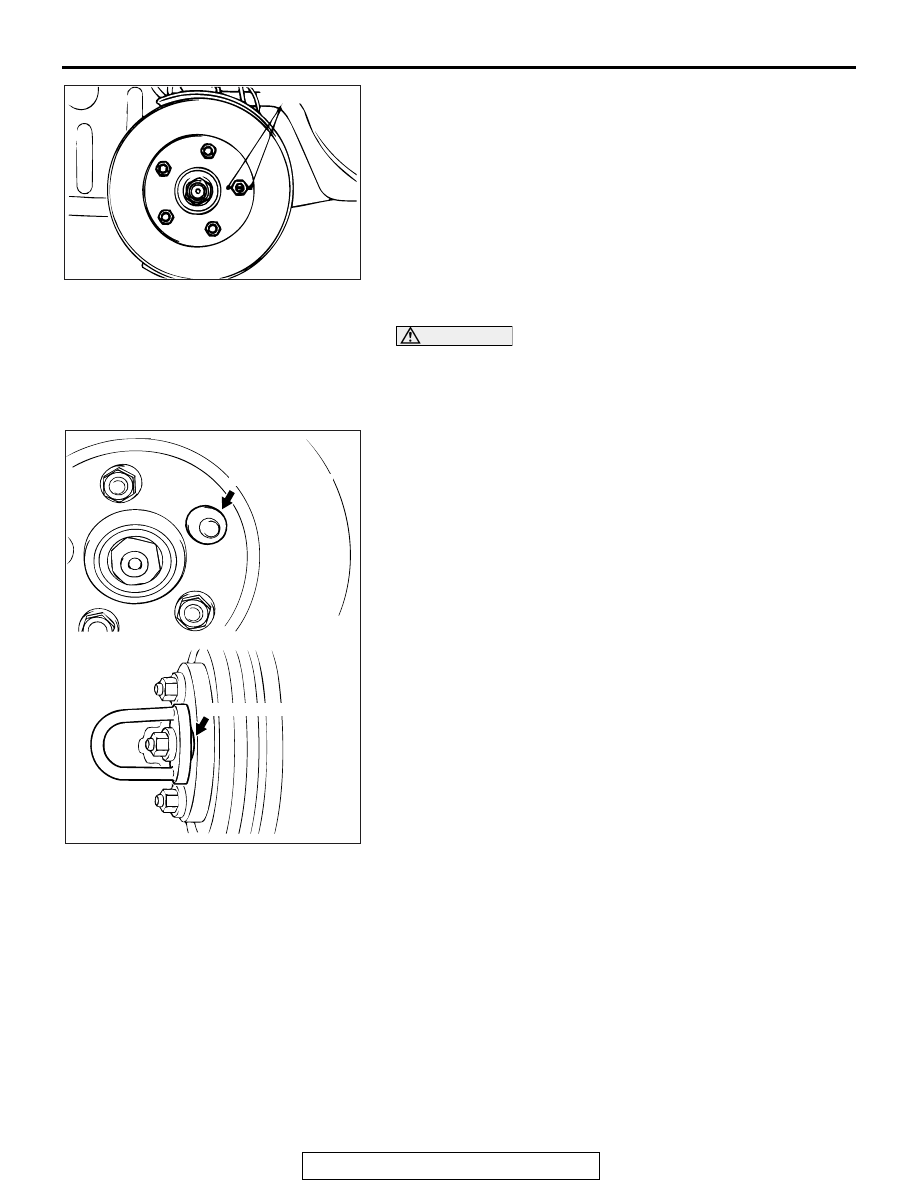

Chalk marks

ON-VEHICLE SERVICE

TSB Revision

BASIC BRAKE SYSTEM

35A-23

(1) Before removing the brake disk, make marks using a

chalk to the stud bolt on the side with the greater runout

and to both sides of the stud bolt.

(2) Check the wheel bearing axial looseness. (Refer to

GROUP 26

− On-vehicle Service, Wheel Bearing End

Play Check

<Front> or GROUP 27

− On-vehicle

Service, Wheel Bearing End Play Check

<Rear>.)

(3) When the looseness is within the limit value, install the

brake disk after changing the phase between the hub and

the brake disk, then check the runout of the brake disk

again.

CAUTION

• After a new brake disk is installed, always grind the

brake disk with on-the-car type brake lathe. If this step

is not carried out, the brake disk run-out exceeds the

specified value, resulting in judder.

•

AC006226 AE

M12 Flat washer

M12 Flat washer

When the on-the-car type lathe is used, first install M12

flat washer on the stud bolt in the brake disk side

according to the figure, and then install the adapter. If

the adapter is installed with M12 flat washer not seated,

the brake disk rotor may be deformed, resulting in inac-

curate grinding.

• Grind the brake disk with all wheel nuts diagonally and

equally tightened to the specified torque 100 N

⋅ m (74

ft-lb). When all numbers of wheel nuts are not used, or

the tightening torque is excessive or not equal, the

brake disk rotor or drum may be deformed, resulting in

judder.

5. If the run-out cannot be corrected by changing the phase of

the brake disk, replace the brake disk or grind it with the

on-the-car type brake lathe ("MAD, DL-8700PF" or

equivalent).