Mitsubishi Evolution X. Manual - part 269

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13A-53

DIAGNOSIS

Required Special Tools

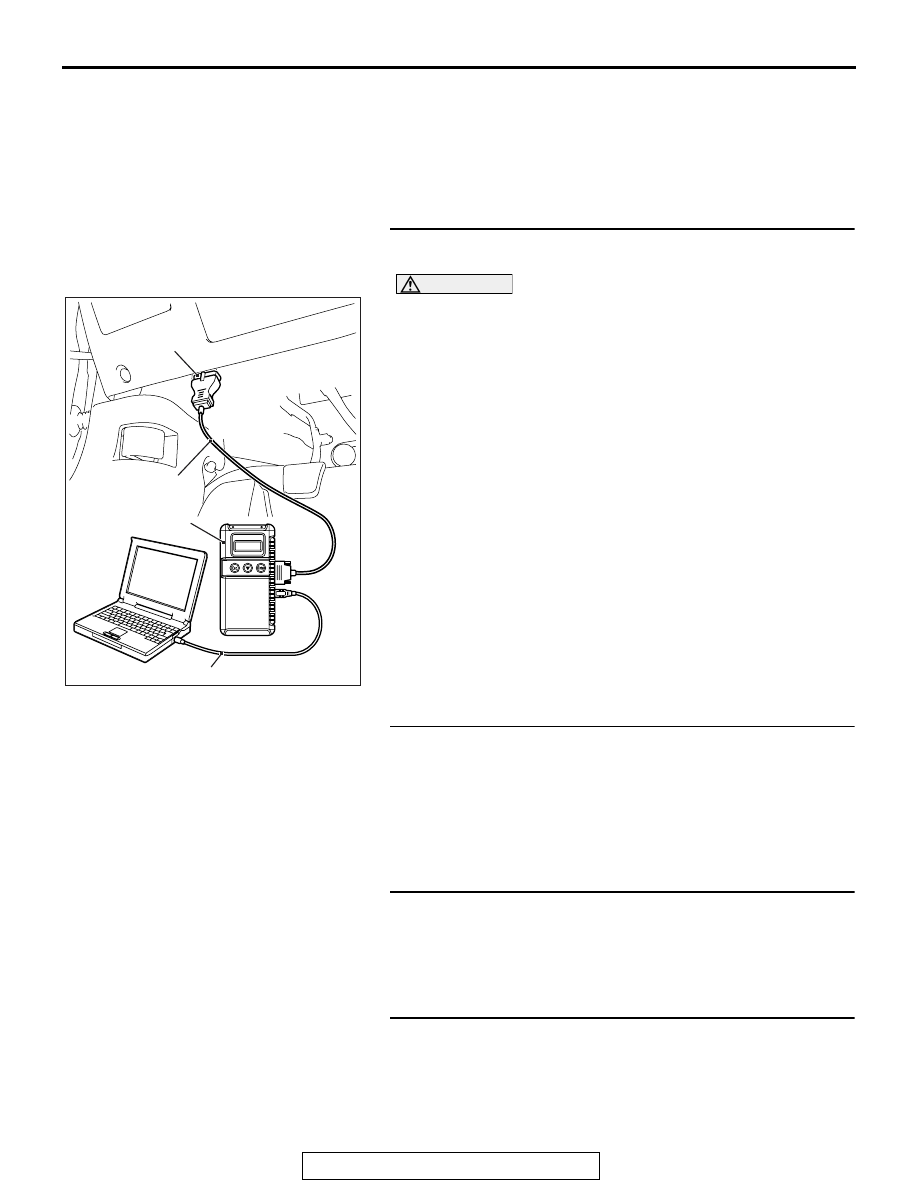

• MB991958: Scan tool (M.U.T.-III Sub Assembly)

• MB991824: V.C.I.

• MB991827: USB Cable

• MB991910: Main Harness A

STEP 1. Using scan tool MB991958, read the diagnostic

trouble code (DTC).

CAUTION

To prevent damage to scan tool MB991958, always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting scan tool MB991958.

(1) Connect scan tool MB991958 to the data link connector.

(2) Turn the ignition switch to the "ON" position.

(3) Set scan tool MB991958, read the DTC.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the diagnostic trouble code other than P0011 set?

YES : Refer to, Diagnostic Trouble Code Chart

NO : Go to Step 2.

STEP 2. Check intake engine oil control valve itself.

• Check intake engine oil control valve itself (Refer to Engine

Oil Control Valve Check

).

Q: Is the check result normal?

YES : Go to Step 3.

NO : Replace intake engine oil control valve. Then go to

Step 6.

STEP 3. Check oil passage of intake variable valve timing

control system for being clogged.

Q: Is the check result normal?

YES : Go to Step 4.

NO : Repair it. Then go to Step 6.

STEP 4. Check intake variable valve timing sprocket

operation mechanism for being stuck.

Q: Is the check result normal?

YES : Go to Step 5.

NO : Repair it. Then go to Step 6.

AC608435

Data link connector

MB991827

MB991824

MB991910

AB