Mitsubishi Lancer Evolution X. Manual - part 343

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13A-437

DIAGNOSIS

Required Special Tools:

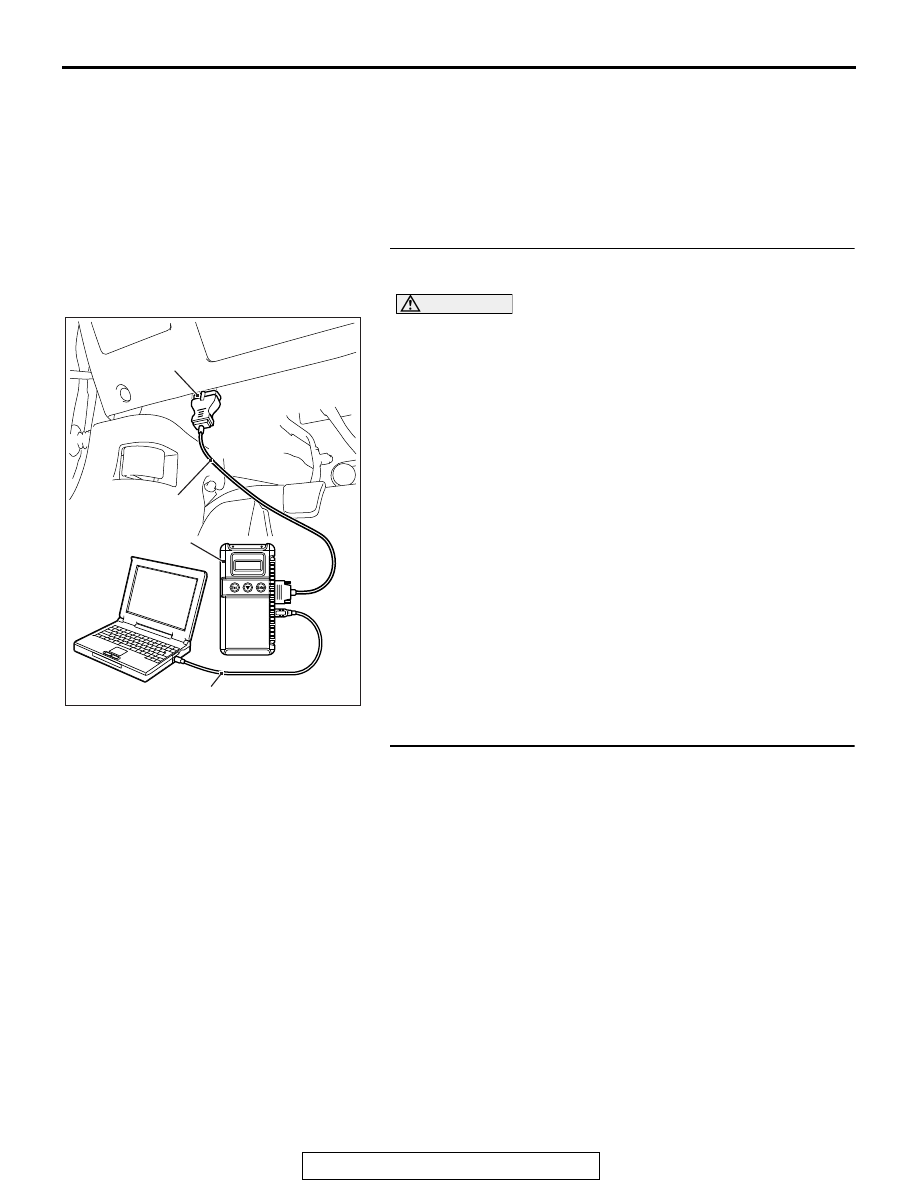

• MB991958: Scan tool (M.U.T.-III Sub Assembly)

• MB991824: V.C.I.

• MB991827: USB Cable

• MB991910: Main Harness A

• MB992110: Power Plant ECU Check Harness

STEP 1. Using scan tool MB991958, check actuator test

item 10: Evaporative Emission Purge Solenoid.

CAUTION

To prevent damage to scan tool MB991958, always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting scan tool MB991958.

(1) Connect scan tool MB991958 to the data link connector.

(2) Turn the ignition switch to the "ON" position.

(3) Set scan tool MB991958 to the actuator test mode for item

10, Evaporative emission purge solenoid.

• An operation sound should be heard and vibration

should be felt when the evaporative emission purge

solenoid is operated.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the solenoid operating properly?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points − How

Cope with Intermittent Malfunctions

.

NO : Go to Step 2.

STEP 2. Check harness connector B-12 at the evaporative

emission purge solenoid for damage.

Q: Is the harness connector in good condition?

YES : Go to Step 3.

NO : Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection

. Then go to Step 10.

AC608435

Data link connector

MB991827

MB991824

MB991910

AB