Mitsubishi 380. Manual - part 975

INPUT SHAFT

MANUAL TRANSMISSION OVERHAUL

22B-13

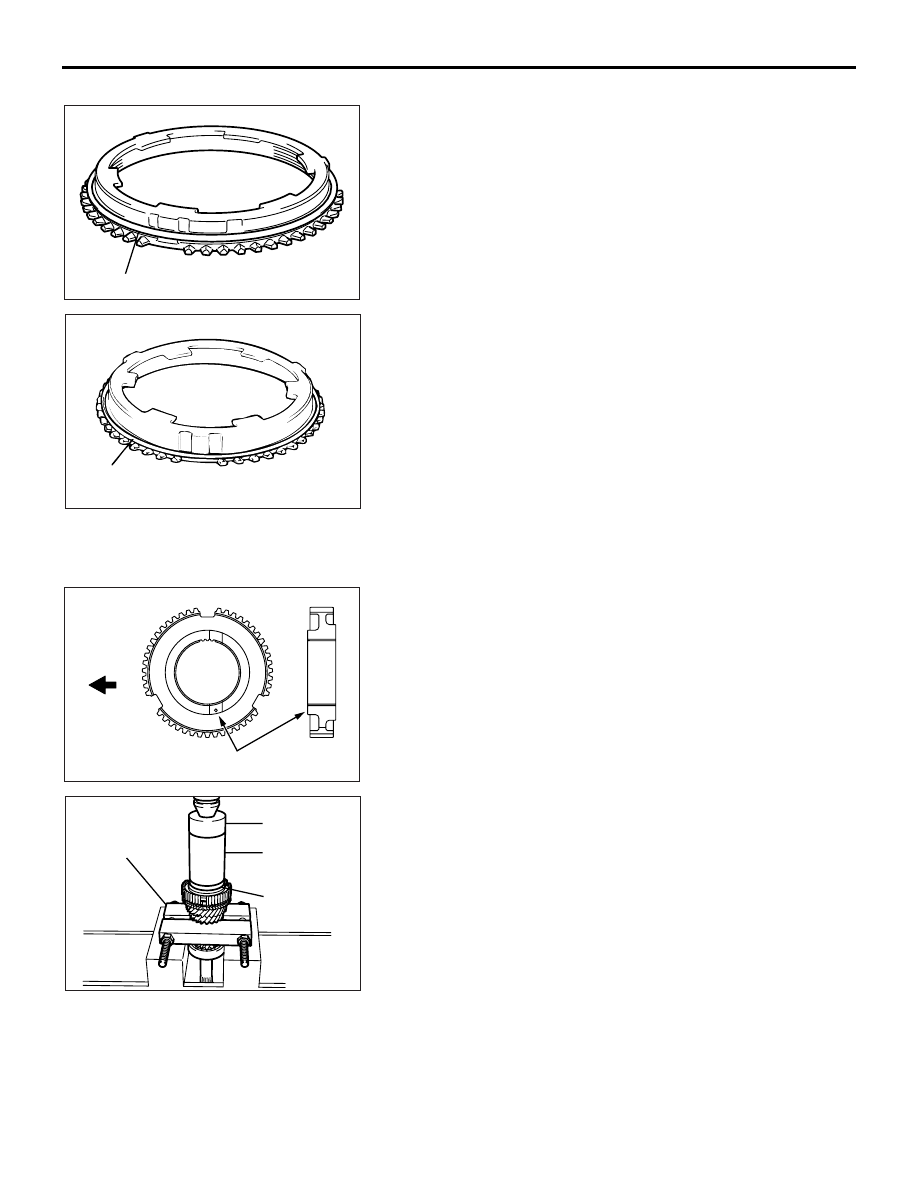

>>D<< SYNCHRONIZER SPRING INSTALLATION

AK201638AD

Synchronizer spring

AKX00951

Synchronizer

spring

AE

Install the synchronizer spring to the illustrated position of the

synchronizer ring and outer synchronizer ring.

.

>>E<< 3RD-4TH SPEED SYNCHRONIZER HUB

INSTALLATION

AK302753AB

Installation

direction

Groove

AK201639

MD998813

MD998812

MD998825

MD998801

AD

1. Using special tool Bearing remover (MD998801), support

the 2nd speed gear portion of the input shaft, and then set

them on the press.

2. Make sure that the inner synchronizer ring has been

perfectly matched to the 3rd speed gear cone.

3. Check the installation direction of the 3rd-4th speed

synchronizer hub, and put it on the input shaft.

4. Using special tools, press install the 3rd-4th speed

synchronizer hub with the press.

• Installer cap (MD998812)

• Installer-100 (MD998813)

• Installer adapter (MD998825)

5. Make sure that the outer synchronizer ring can rotate freely.

.