Mitsubishi 380. Manual - part 946

ANTI-LOCK BRAKING SYSTEM (ABS) DIAGNOSIS

ANTI-LOCK BRAKING SYSTEM (ABS)

35B-9

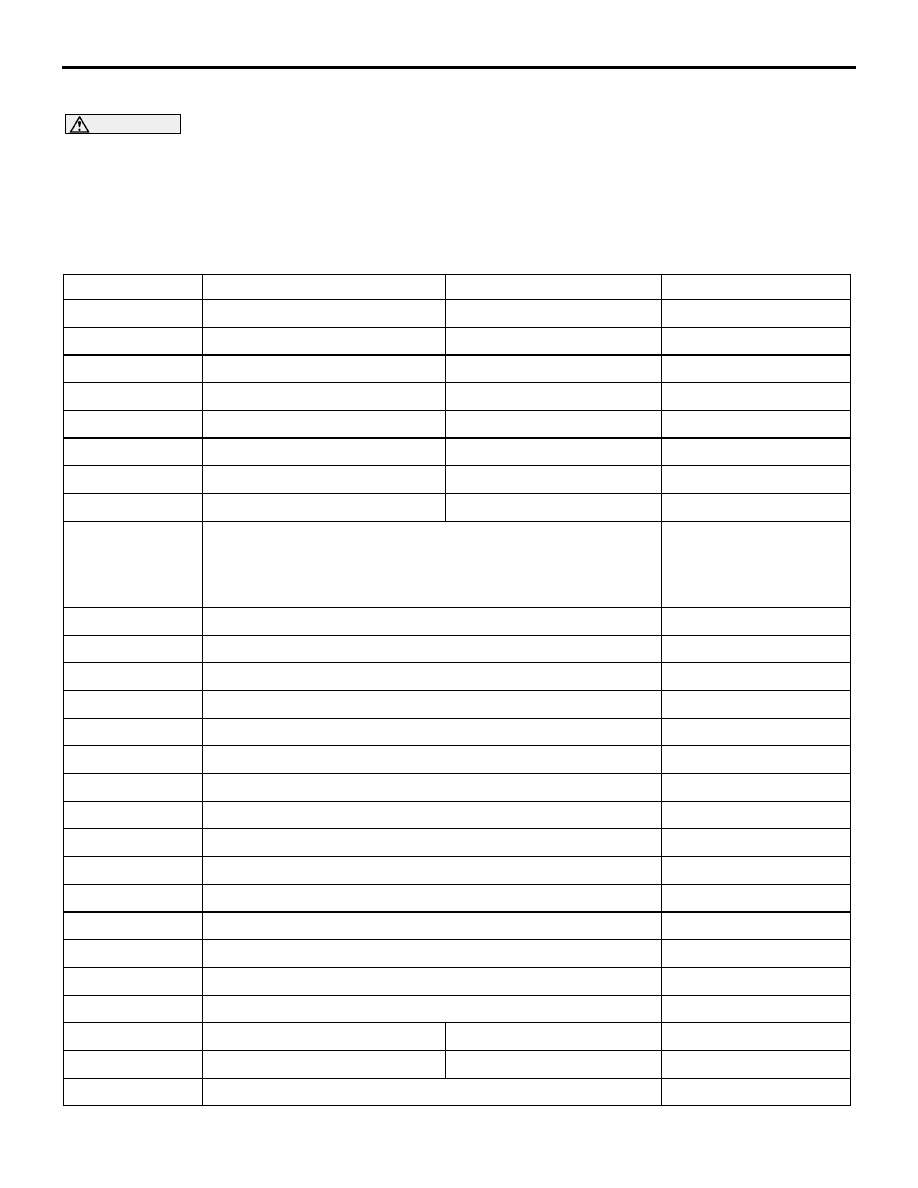

DIAGNOSTIC TROUBLE CODE CHART

M1352011300601

CAUTION

During diagnosis, a DTC code associated with

another system may be set when the ignition

switch is turned on with connector(s) discon-

nected. On completion, confirm all systems for

DTCs. If DTC code(s) are set, erase them all.

Follow the inspection chart that is appropriate for the

diagnostic trouble code.

DTC

INSPECTION ITEM

DIAGNOSTIC CONTENT

REFERENCE PAGE

C1200

Front right wheel speed sensor

Open circuit or short circuit

C1201

Front right wheel speed sensor

Abnormal output signal

C1205

Front left wheel speed sensor

Open circuit or short circuit

C1206

Front left wheel speed sensor

Abnormal output signal

C1210

Rear right wheel speed sensor

Open circuit or short circuit

C1211

Rear right wheel speed sensor

Abnormal output signal

C1215

Rear left wheel speed sensor

Open circuit or short circuit

C1216

Rear left wheel speed sensor

Abnormal output signal

C1225

Deviation between wheel speeds

or refer to the

above appropriate

abnormal output sensor

signal

C1226

ABS front right (FR) inlet solenoid valve

C1231

ABS front right (FR) outlet solenoid valve

C1236

ABS front left (FL) inlet solenoid valve

C1241

ABS front left (FL) outlet solenoid valve

C1246

ABS rear right (RR) inlet solenoid valve

C1251

ABS rear right (RR) outlet solenoid valve

C1256

ABS rear left (RL) inlet solenoid valve

C1261

ABS rear left (RL) outlet solenoid valve

C1266

Motor pump system (seizure)

C1273

Motor relay (drive circuit) problem (stays off)

C1274

Motor relay (drive circuit) problem (stays on)

C1276

Valve relay malfunction

C1278

Valve relay problem (stays off)

C1279

Valve relay problem (stays on)

C1607

ABS-ECU malfunction

C1860

Power supply system

Abnormal rise in voltage

C1861

Power supply system

Abnormal drop in voltage

U1073

CAN-Bus off