Mitsubishi 380. Manual - part 927

CLOCK DISPLAY

CHASSIS ELECTRICAL

54A-242

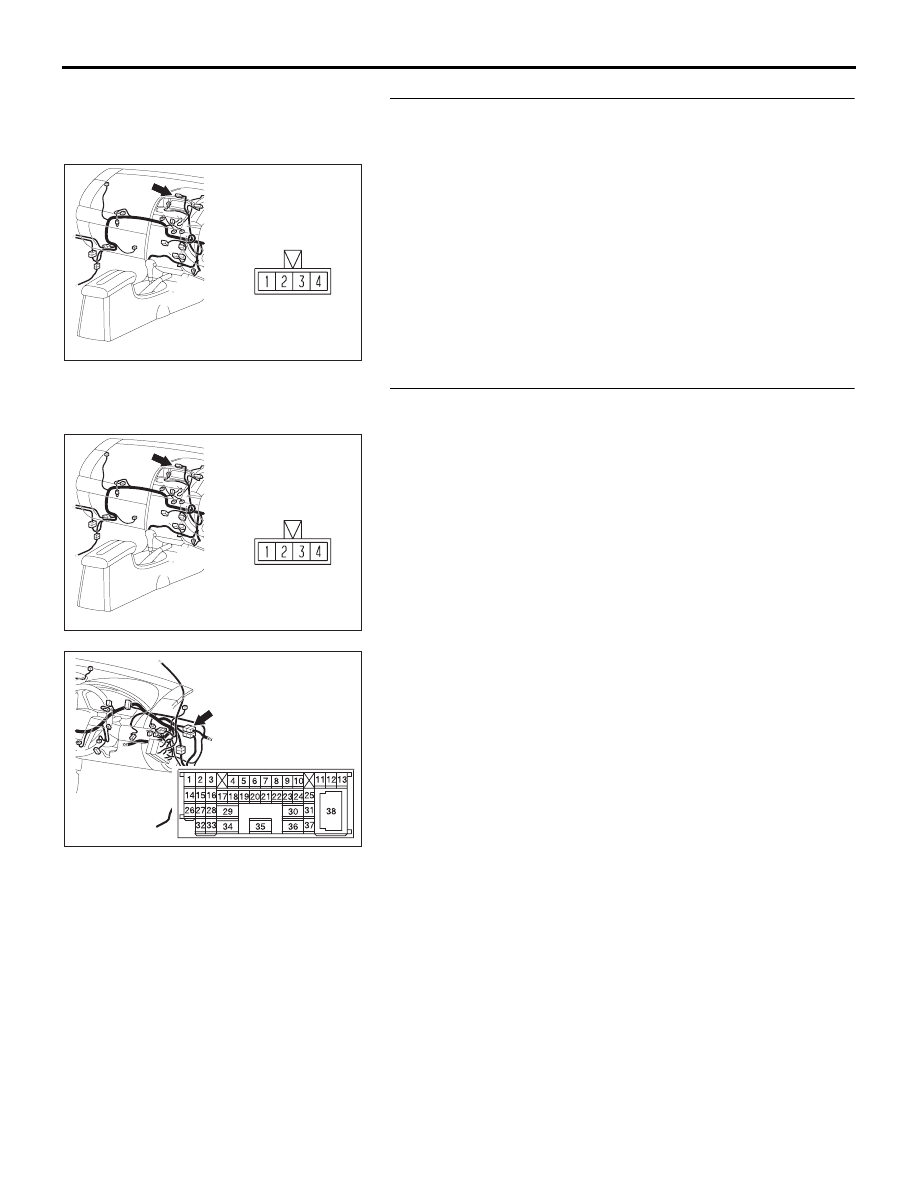

STEP 8. Check clock display unit connector C-06 for

loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Is clock display unit connector C-06 in good condition?

YES : Go to Step 9.

NO : Repair or replace the connector. Refer to GROUP

00E, Harness Connector Inspection

. The

clock display unit should work normally.

STEP 9. Check the wiring harness between C-06 (terminal

3) and ignition switch (ACC).

NOTE: Also check intermediate connector C-29 for loose, cor-

roded, or damaged terminals, or terminals pushed back in the

connector. If intermediate connector C-29 is damaged, repair or

replace the wiring harness. Refer to GROUP 00E, Harness

Connector Inspection

.

Q: Is the wiring harness between C-06 (terminal 3) and

ignition switch (ACC) in good condition?

YES : There is no action to be taken.

NO : Repair the wiring harness. The clock display unit

should work normally.

16DB609A

CONNECTOR: C-06

C-06

16DB609A

CONNECTOR: C-06

C-06

52DB014A

CONNECTOR: C-29