Mitsubishi 380. Manual - part 82

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)

54B-325

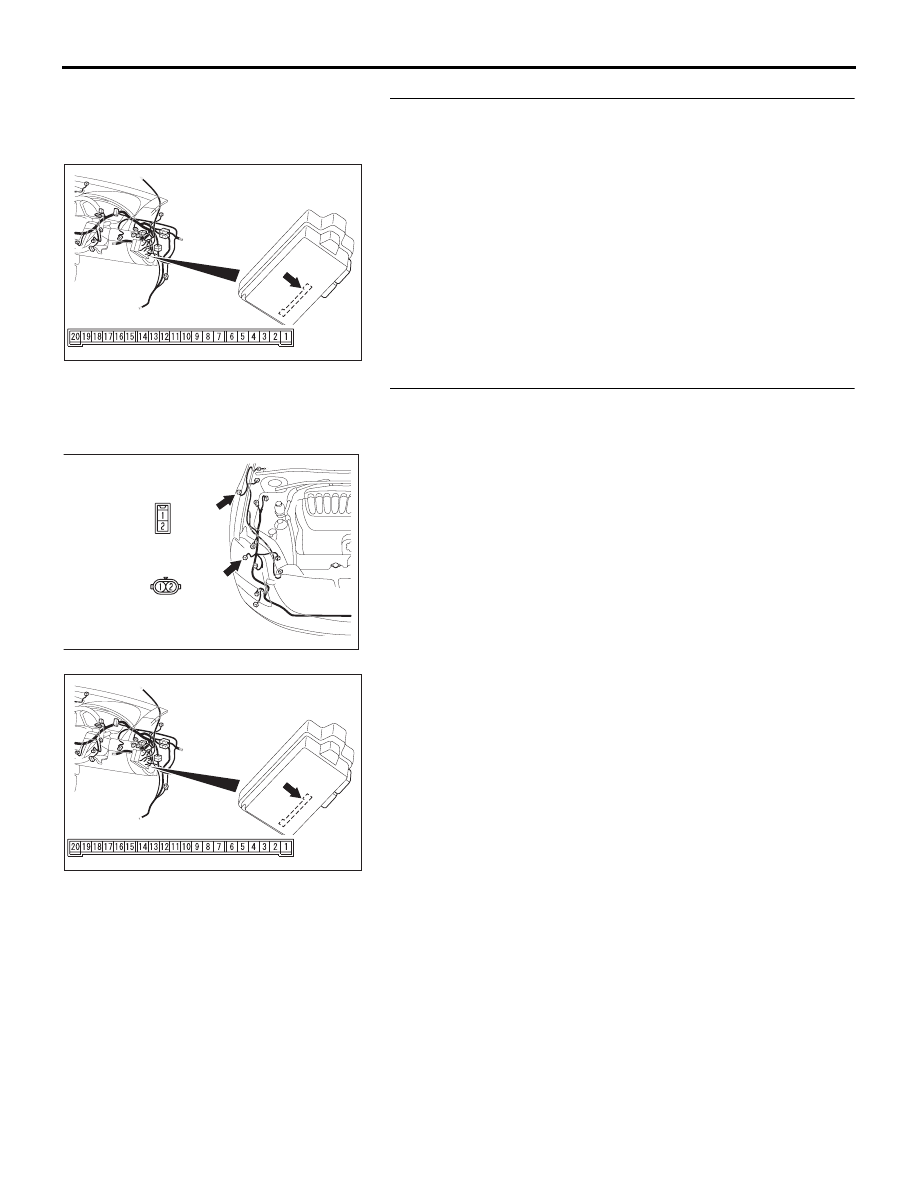

STEP 18. Check ETACS-ECU connector C-219 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is ETACS-ECU connector C-219 in good condition?

YES : Go to Step 19.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

. Verify that the turn-signal lamps illuminate

normally.

STEP 19. Check the wiring harness between front

combination lamp (RH) connector A-34 (terminal 1) and

ETACS-ECU connector C-219 (terminal 9).

54DB014A

CONNECTOR: C-219

JUNCTION BLOCK SIDE

JUNCTION BLOCK

(REAR VIEW)

16DB444A

CONNECTOR: A-34, A-35

A-34

A-35

54DB014A

CONNECTOR: C-219

JUNCTION BLOCK SIDE

JUNCTION BLOCK

(REAR VIEW)