Mercedes-Benz ML320. Manual - part 628

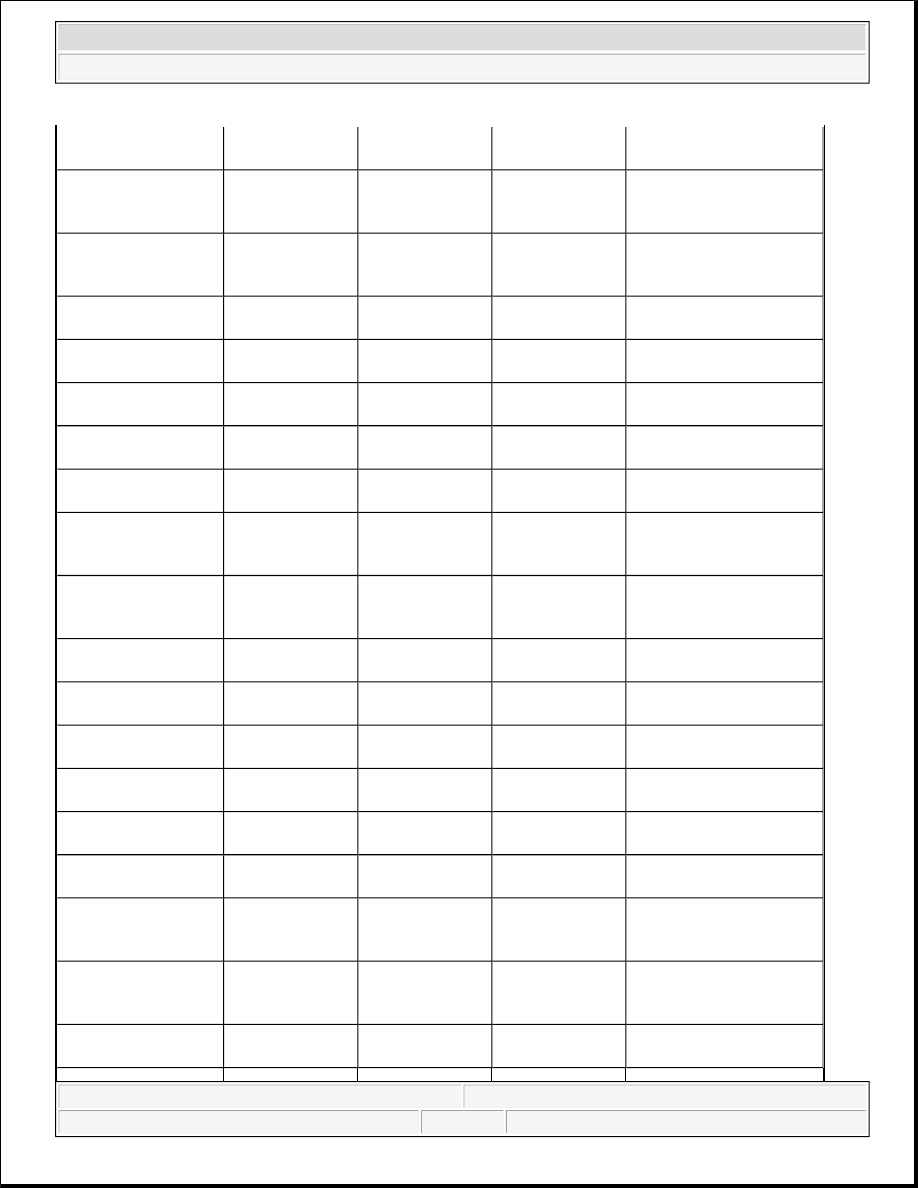

Galp Formula XLD,

SAE 5W-30

X

Petrogal S.A., Lisbon,

Portugal

Gulf Avantgarde K

5W-30

X

S.A. Espanola de

Lubrificantes, Madrid,

Spain

Gulf Formula

Extreme 0W-30

X

S.A. Espanola de

Lubrificantes, Madrid,

Spain

Gulf Formula GX,

SAE 5W-30

X

Gulf Oil International,

London, England

Igol Process Compact

P

X

Igol France, Amiens -

Cedex/France

INA Futura MB

X

INA Maziva Rijeka,

Rijeka, Croatia

Labo MB 229.5

X

Fuchs Labo Auto S.A.,

Rueil-Malmaison, France

Liqui Moly Longtime

High Tech

X

Liqui Moly GmbH, Ulm,

Germany

megol Motorenoel

New Generation

X

Meguin GmbH & Co. KG

Mineraloelwerke,

Saarlouis, Germany

Midland Crypto 5W-

30

X

Oel-Brack AG,

Hunzenschwil,

Switzerland

Mobil 1 0W-40

X

Exxon Mobil Corporation,

Fairfax, Virginia, USA

Mobil 1 Turbo Diesel

0W-40

X

Exxon Mobil Corporation,

Fairfax, Virginia, USA

Mobil SHC Formula

MB 5W-30

X

Exxon Mobil Corporation,

Fairfax, Virginia, USA

Motorex Profile M-

XL 5W-30

X

Bucher AG Langenthal,

Langenthal/Switzerland

Motul 8100 X-max

5W-30

X

Motul,

Aubervilliers/France

Motul Specific MB

229.5 5W-30

X

Motul,

Aubervilliers/France

OMV full syn MB

X

OMV Refining &

Marketing GmbH,

Vienna, Austria

OMV full syn plus

SAE 5W-30

X

OMV Refining &

Marketing GmbH,

Vienna, Austria

Panolin Exclusive BD

X

Panolin AG, Madetswil,

Switzerland

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me