Mazda Engine SKYACTIV-G 2.5. Manual - part 9

MECHANICAL

01-10–20

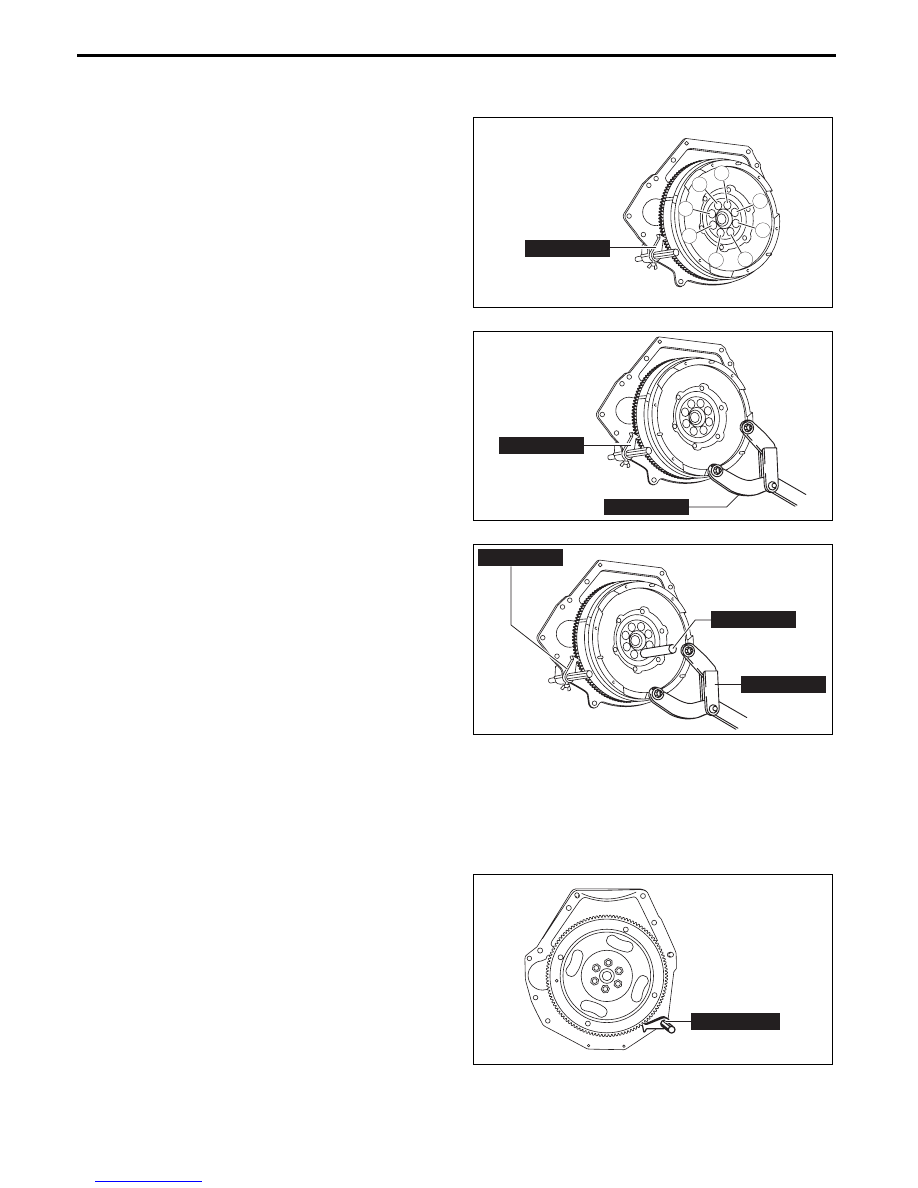

Dual-mass Flywheel (MTX)/ Drive Plate (ATX) Installation Bolt Disassembly Note

Dual-mass flywheel installation bolt (MTX)

1. Hold the crankshaft using the

SST (49 E011 1A0).

2. Loosen the bolts uniformly and gradually in the

order shown in the figure.

Note

• If the bolt installation holes are not

positioned properly, perform the following

procedure:

(1) Install the

SST (49 S120 710) to the dual-

mass flywheel.

(2) Rotate the dual-mass flywheel (secondary

flywheel side) using the

SST (49 S120 710).

(3) When the bolt installation holes are positioned

properly, hold the position and remove one of

the bolts.

(4) After removing the bolt, set up the

SST (49

G033 102) to lock the dual-mass flywheel

(secondary flywheel side) against rotation.

Warning

• If all of the bolts are removed without

locking the dual-mass flywheel

(secondary flywheel side) against

rotation, the dual-mass flywheel (primary

or secondary flywheel side) may rotate,

resulting in injury. Therefore, always set

up the SST (49 G033 102).

• When the bolts are removed from the

dual-mass flywheel, always cover the bolt

holes using tape. If the SST (49 G033 102) is removed while the operator’s finger is inserted in the

bolt hole, the dual-mass flywheel may rotate and the operator could be injured.

(5) Remove the remaining bolts.

Drive plate installation bolt (ATX)

1. Hold the crankshaft using the

SST.

2. Loosen the bolts uniformly and gradually in the

order shown in the figure.

8

4

1

6

2

7

5

3

49 E011 1A0

ac5wzw00005660

49 E011 1A0

49 S120 710

am6xuw00005540

49 E011 1A0

49 S120 710

49 G033 102

am6xuw00005541

49 E011 1A0

bpe1ze00000092