Mazda 6. Manual - part 264

P–112

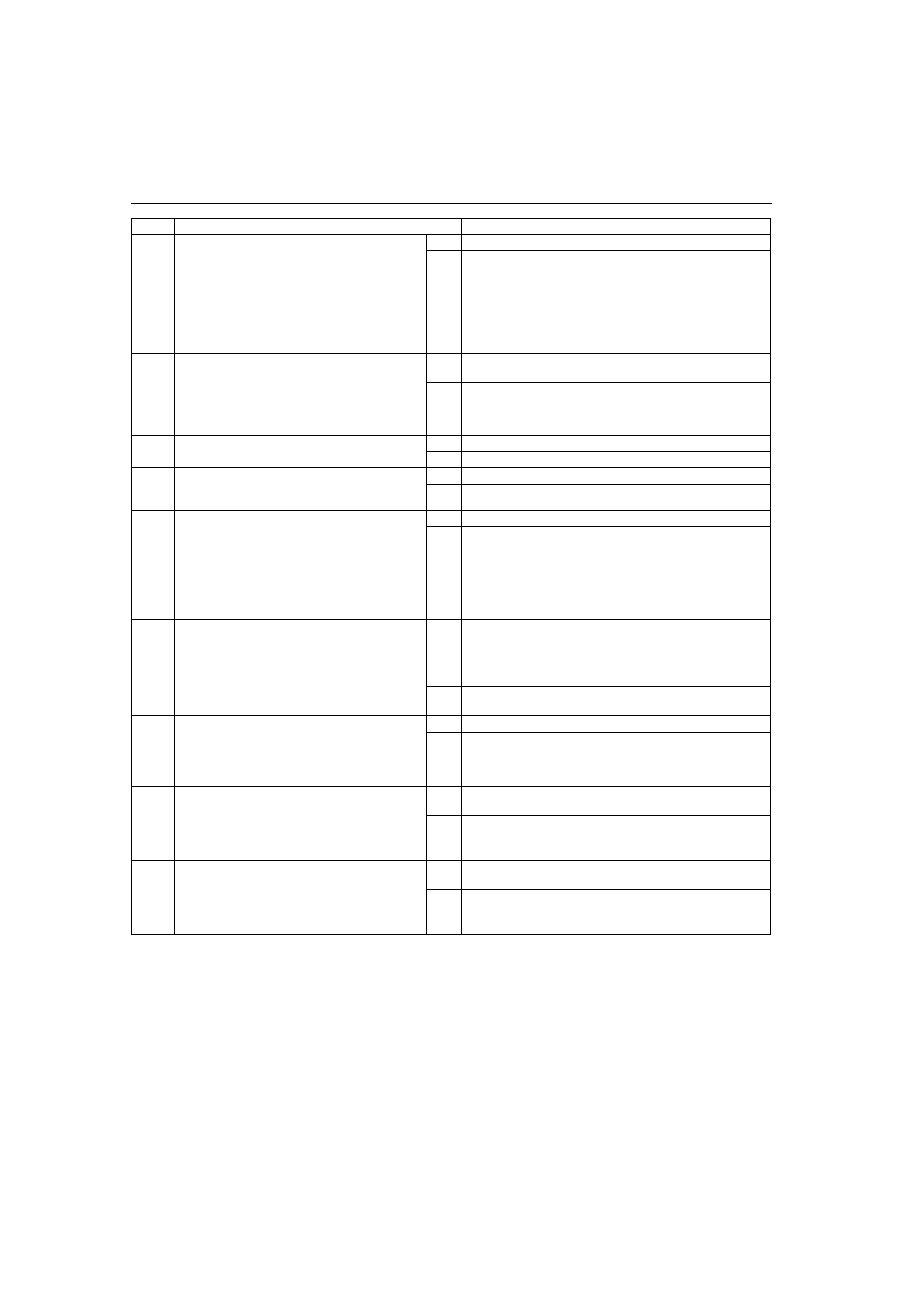

TROUBLESHOOTING (ABS/TCS/DYNAMIC STABILITY CONTROL)

4

INSPECT PID/DATA IN ABS/TCS HU/CM

Inspect the following items using WDS or

equivalent PID/DATA monitor function.

• ABS_LAMP (ABS warning light)

• BRAKE_ LAMP (BRAKE system warning

light)

• ABS_VOLT (power supply voltage)

Is ABS_LAMP and BRAKE_LAMP ON after

more than 4 seconds with ignition switch on?

Yes

Go to Step 7.

No

Go to next step.

5

INSPECT ABS/TCS HU/CM IGNITION POWER

SUPPLY SYSTEM (TERMINAL Z)

Check the voltage for PID/DATA monitor

ABS_VOLT item.

Specification: about 10 V

Is voltage within specification?

Yes

Replace ABS/TCS HU/CM (open or short in ground circuit in

ABS/TCS HU/CM)

No

Go to next step.

6

INSPECT BATTERY

Is battery voltage normal?

Yes

Go to next step.

No

Inspect battery and charging system.

7

INSPECT CHARGING SYSTEM

Is battery voltage normal with electrical load (A/

C, headlight, etc.) on and engine idling?

Yes

Go to Step 7.

No

Inspect charging system (drive belt tension, generator, etc.).

*

8

INSPECT WIRING HARNESS BETWEEN ABS/

TCS HU/CM POWER SUPPLY AND ABS/TCS

HU/CM FOR CONTINUITY

Disconnect ABS/TCS HU/CM connector.

Connect the SST (49 G066 001) (vehicle

harness side only).

Is voltage approximately 12 V at SST

connector terminal Z?

Yes

Go to next step.

No

Check for connection of ABS/TCS HU/CM connector

securely.

*

9

INSPECT WIRING HARNESS BETWEEN ABS/

TCS HU/CM GROUND FOR CONTINUITY

Turn ignition switch to LOCK.

Is there continuity between SST connector

terminal AC and ground?

Yes

If a malfunction error message is displayed on WDS or

equivalent in Step 1 inspection, go to next step.

If a malfunction error message is not displayed on WDS or

equivalent in Step 1 inspection, troubleshooting is

completed.

No

Repair wiring harness between ABS/TCS HU/CM and

ground.

*

10

INSPECT WIRING HARNESS BETWEEN ABS/

TCS HU/CM AND DLC-2 (DATA LINK

CONNECTOR-2) FOR CONTINUITY

Is there continuity between SST connector

terminal X and DLC-2?

Yes

Go to next step.

No

Repair wiring harness between ABS/TCS HU/CM and

DLC-2.

11

*

INSPECT WIRING HARNESS BETWEEN

ABS/TCS HU/CM AND DLC-2 (DATA LINK

CONNECTOR-2) FOR SHORT TO BATTERY

Is voltage approximately 12 V at SST

connector terminal X?

Yes

Repair wiring harness between ABS/TCS HU/CM and

DLC-2.

No

Go to next step.

12

*

INSPECT WIRING HARNESS BETWEEN

ABS/TCS HU/CM AND DLC-2 (DATA LINK

CONNECTOR-2) FOR SHORT TO GROUND

Is there continuity between SST connector

Terminal X and DLC-2?

Yes

Repair wiring harness between ABS/TCS HU/CM and

DLC-2.

No

Replace ABS/TCS HU/CM (communication circuit

malfunction in ABS/TCS HU/CM)

STEP

INSPECTION

ACTION