Discovery 2. Manual - part 408

ENGINE - TD5

DESCRIPTION AND OPERATION 12-1-29

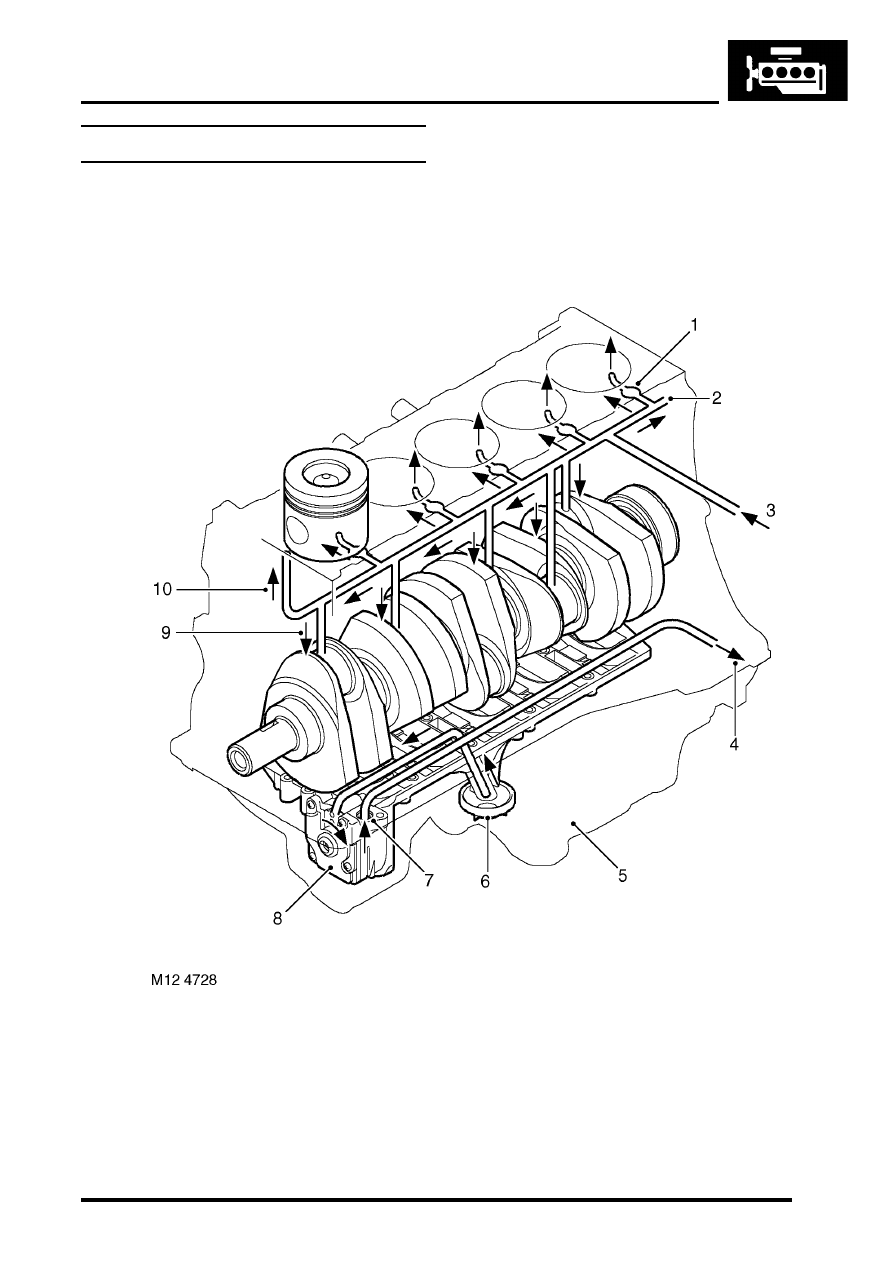

Lubrication circuit

Cylinder block flow

1 Oil squirt jets (5 off)

2 Main oil delivery gallery

3 Inflow from oil cooler housing

4 Flow to oil cooler / filters (from oil pump via

cylinder block)

5 Sump

6 Oil pick-up pipe

7 Flow from oil pump (relief-valve in housing)

8 Oil pump

9 Cross-drilling supply to main and crankshaft

bearings

10 To cylinder head