Discovery 2. Manual - part 163

FRONT AXLE

DESCRIPTION AND OPERATION

54-1

FRONT AXLE

DESCRIPTION AND OPERATION

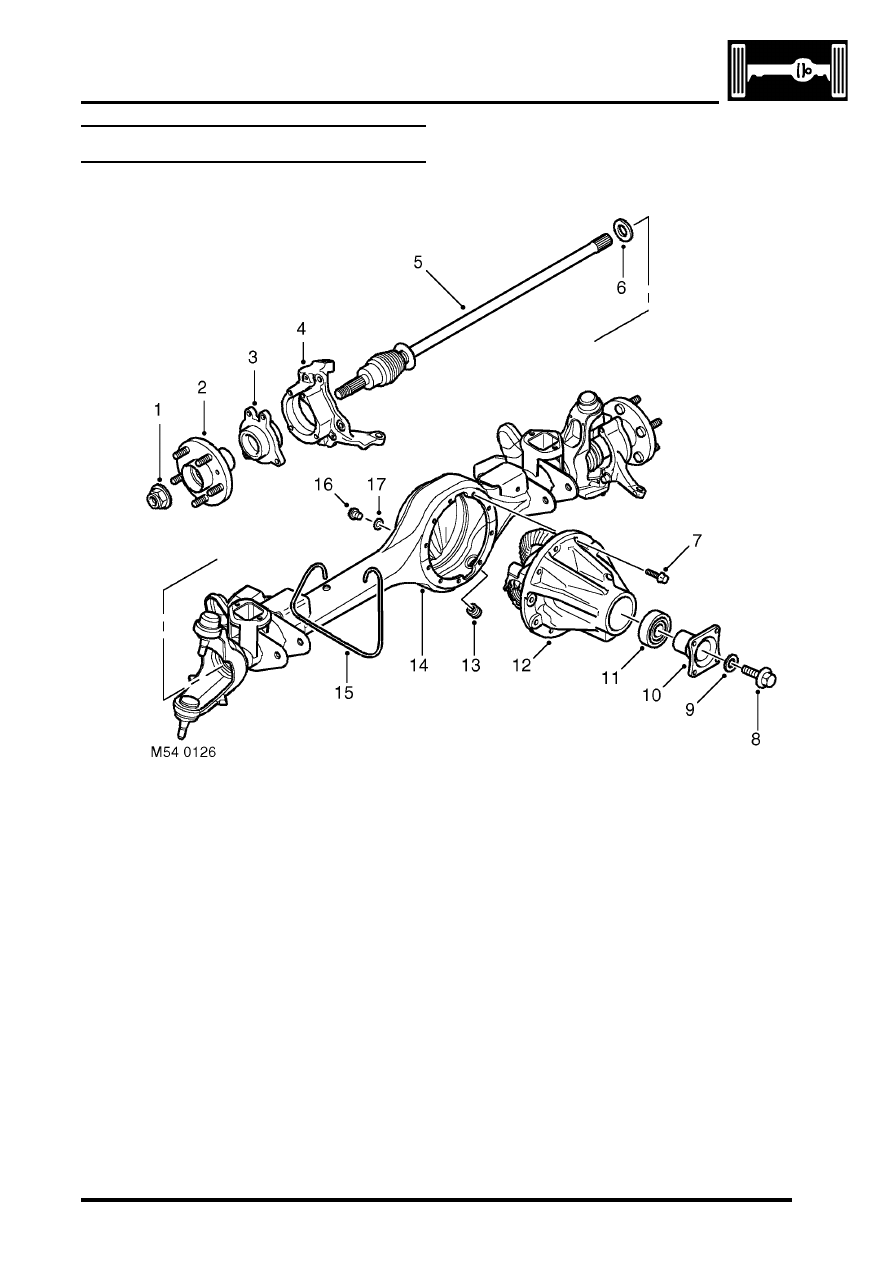

Front axle component layout

1 Stake nut

2 Hub flange

3 Hub bearing

4 Steering knuckle

5 Drive shaft

6 Oil seal

7 Bolt

8 Bolt

9 Washer

10 Drive flange

11 Oil seal

12 Differential unit

13 Drain plug

14 Axle casing

15 Breather tube

16 Oil level plug

17 'O' ring