Defender Electric Diagrams. Manual - part 11

FUSE DETAILS

DEFENDER 90 NAS

REV: 9/97

1

INTRODUCTION

The following tables give details of power supply through the engine and passenger

compartment fuse boxes.

Note: Some fuse numbers may be followed by a letter, either an ‘E’ or a ‘P’. ‘E’ denotes

a fuse located in the engine compartment fuse box, and ‘P’ a fuse located in the

passenger compartment fuse box.

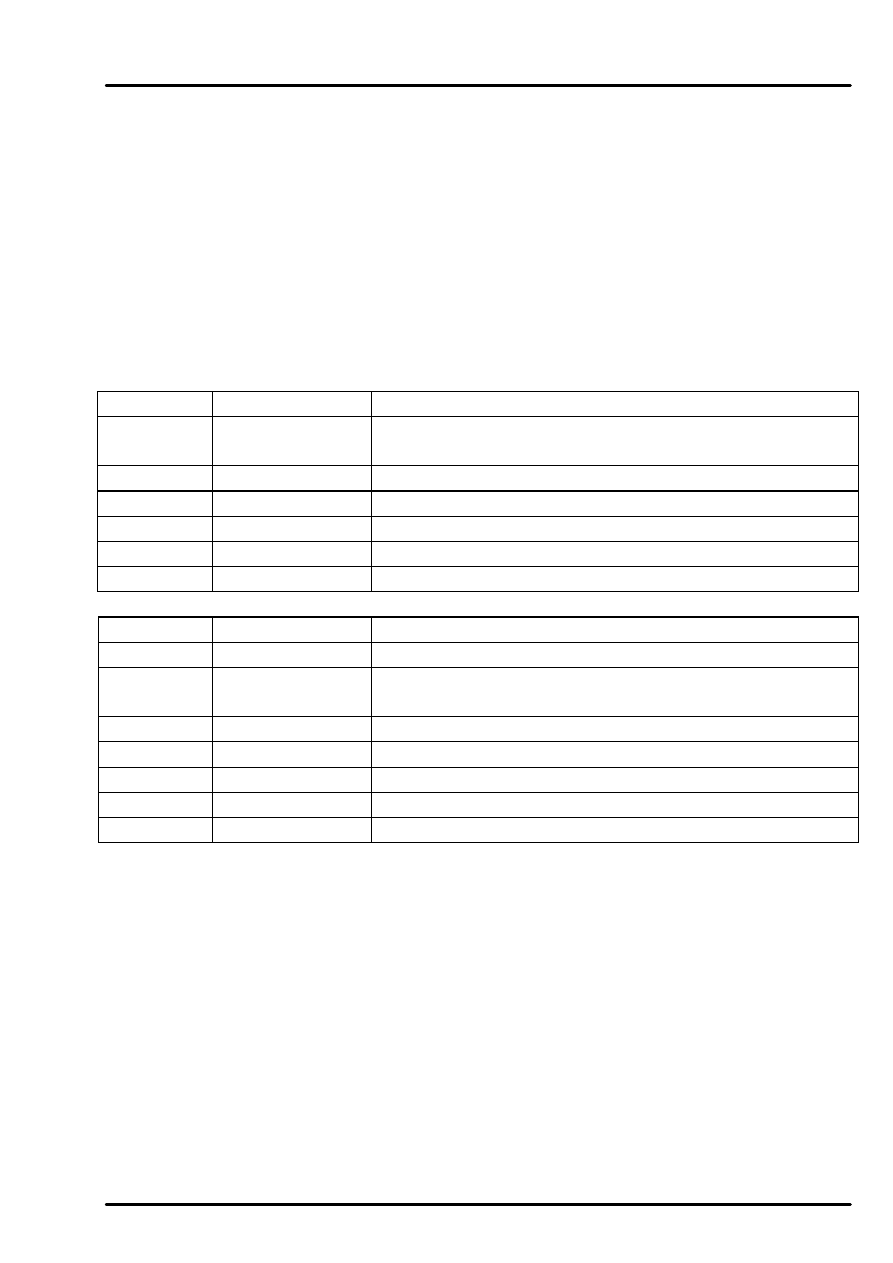

Engine Compartment Fuse Box

Link

Rating

Function

1

100 Amp

Link 3, Link 4, Link 5, Link 6, Fuse 1 (E), Fuse 2 (E), &

Fuse 3 (E).

2

60 Amp

Fuse 13 (P), Fuse 14 (P), Fuse 15 (P), & Fuse 16 (P).

3

60 Amp

Lighting switch.

4

30 Amp

Lighting switch.

5

60 Amp

Fuse 2 (P), Fuse 3 (P), Ignition switch, & Starter relay.

6

30 Amp

Heater rear screen relay.

Fuse

Rating

Function

1

30 Amp

Interior Lamp Unit.

2

20 Amp

Column switch, Multi-function ECU, Interior lamp -

front, Analogue clock, Key-in sensor.

3

30 Amp

Engine immobilisation ECU.

4

10 Amp

Not used.

5

30 Amp

Hazard warning switch.

6

15 Amp

Engine management relay module.

7

20 Amp

Engine management relay module.