Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 887

6E–572

TROOPER 6VE1 3.5L ENGINE DRIVEABILITY AND EMISSIONS

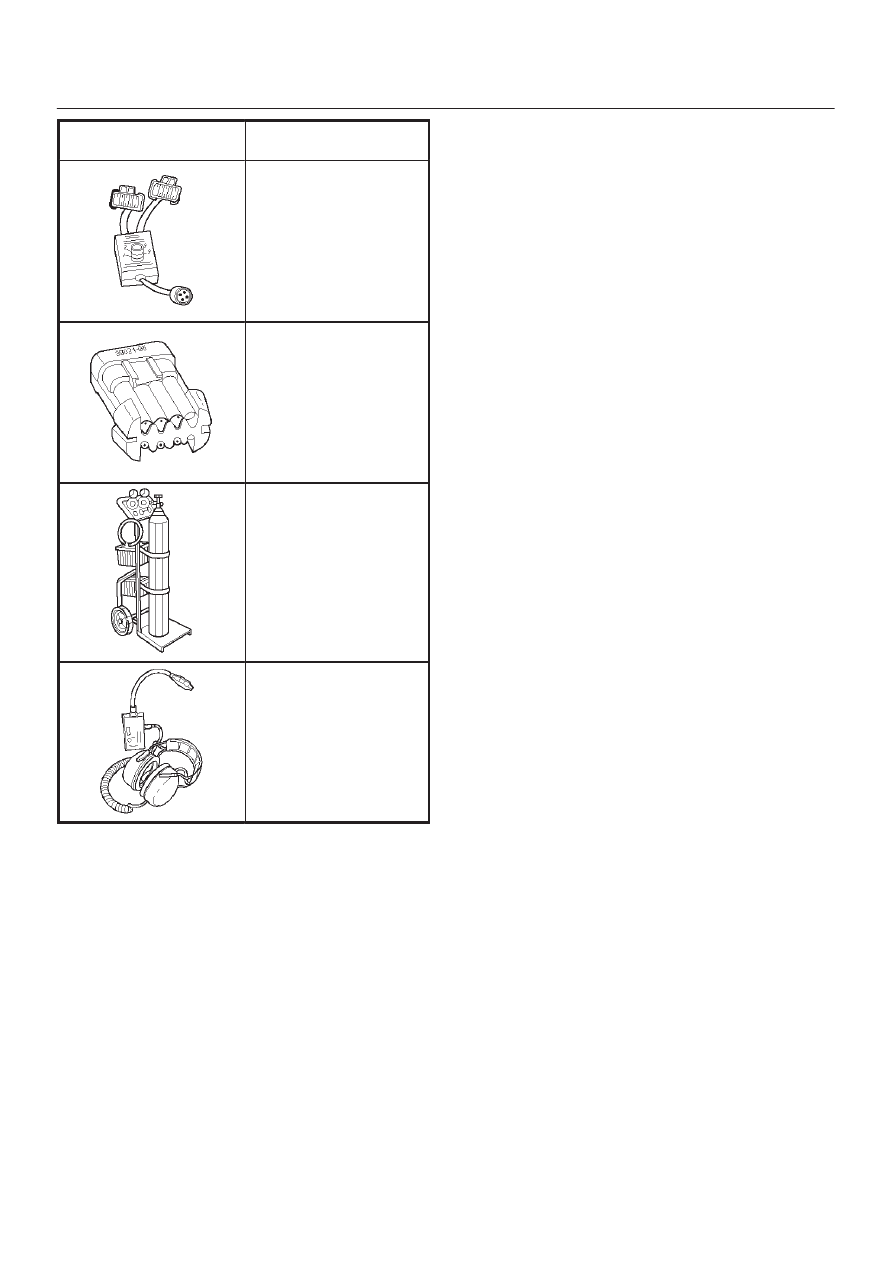

ILLUSTRATION

TOOL NO.

TOOL NAME

J 39021-90

Injector Switch Box

J 39021-65

Injector Test Light

J 41413

!

EVAP Pressure/Purge

Diagnostic Station

J 41416

@

Ultrasonic Leak Detector

1. J 41413 EVAP Pressure/Purge Diagnostic Station is

a multipurpose tool which is used to perform several

diagnostic procedures for enhanced emission

testing. The station will accommodate a nitrogen gas

filled cylinder which is used to pressurize the vehicle

EVAP system for a leakdown test and leak location

test when a vehicle is repaired for leakage in the

enhanced evaporative emission control system. It

also has two additional gauges (inches of mercury

and inches of water) which are used to measure both

source vacuum and EVAP canister purge vacuum to

verify correct operation and vapor flow within the

canister purge circuit.

2. J 41416 Ultrasonic Leak Detector is a

microprocessor-based device used to detect leaks in

the enhanced evaporative emission control system.

The evaporative system is pressurized to 30 inches of

water using the J 41413 EVAP Pressure/Purge

Diagnostic System. Small leaks in the EVAP system

will emit sound at a high frequency undetectable by a

human ear but detectable with the J 41416. The

technician traces along the evaporative system and

can pinpoint leaks due to corroded lines, cracked

hoses, or a damaged EVAP component. The

detector includes a high quality set of headphones to

block out surrounding shop noise and the LED

sensitivity meter allows a visual reference for locating

leaks in conjunction with the audio output heard

through the headphones. Powered by (1) nine volt

battery.