Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 383

6E–562

6VE1 3.5L ENGINE DRIVEABILITY AND EMISSIONS

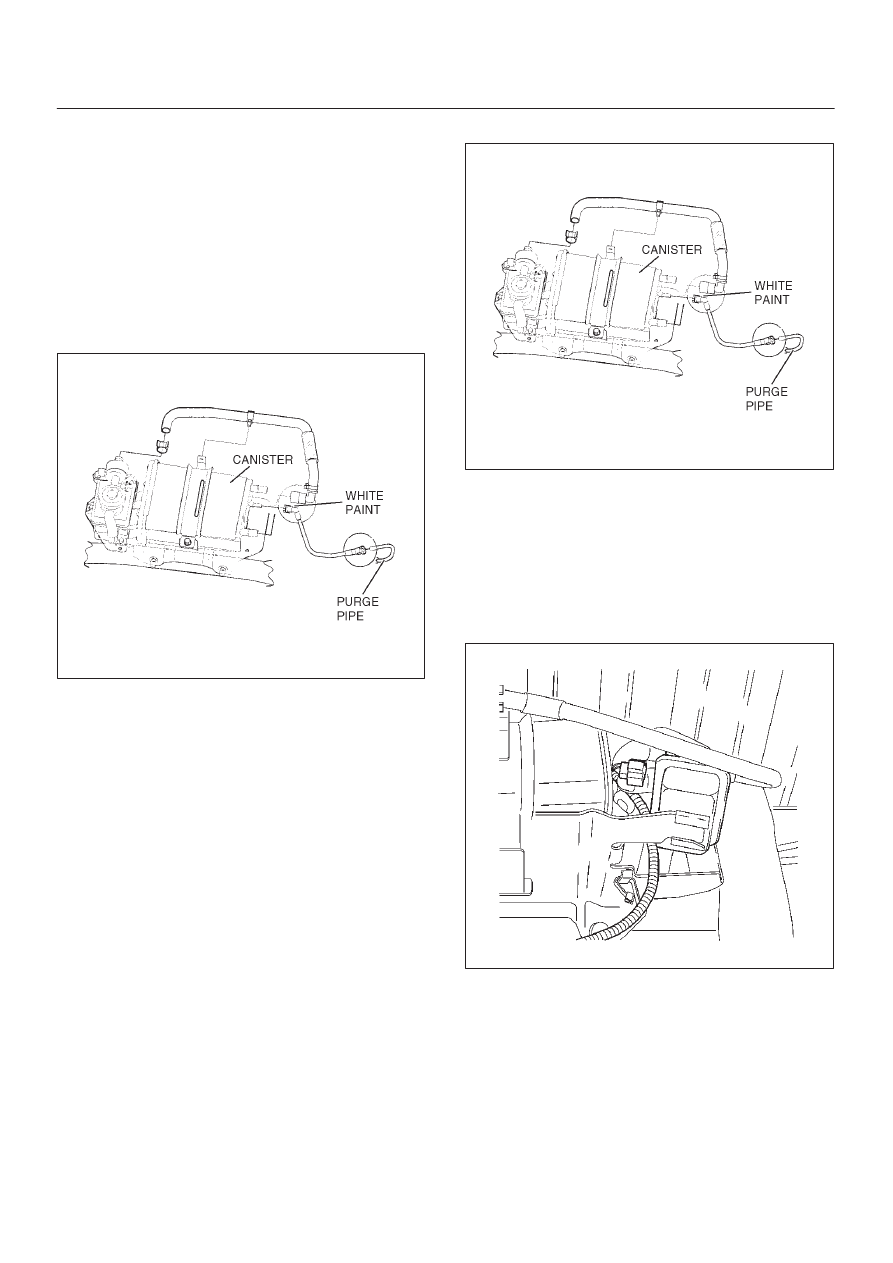

EVAP Canister

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the two hoses from the EVAP canister.

3. Disconnect the fuel vapor connector and the purge

hose from the EVAP canister vent solenoid.

4. Remove the two retaining bolts the EVAP canister to

the mounting bracket on the cross member.

5. Remove the retaining bolt on the mounting bracket

the slide the canister out of mounting bracket.

060R200081

Inspection Procedure

1. Inspect the hoses for cracks and leaks.

2. Inspect the canister for a damaged case.

Installation Procedure

1. Slide the canister into mounting bracket and install

the mounting bracket bolt.

2. Install the retaining bolts the EVAP canister to the

mounting bracket on the cross member.

3. Connect the fuel vapor connector to the EVAP

canister vent solenoid.

4. Connect the two hoses to the EVAP canister.

060R200081

5. Disconnect the negative battery cable.

EVAP Canister Vent Solenoid

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the connector and hose.

014RW132