Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 349

6E–426

6VE1 3.5L ENGINE DRIVEABILITY AND EMISSIONS

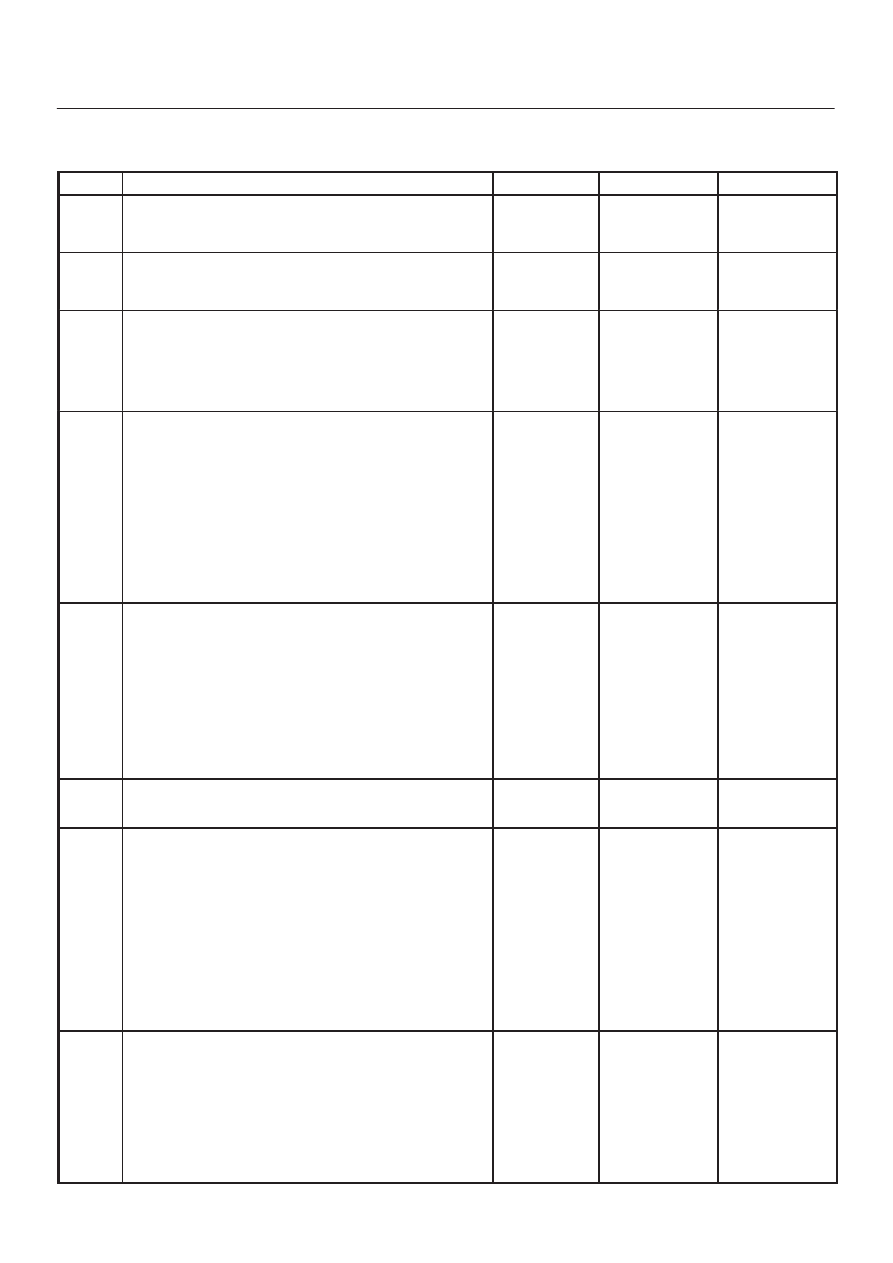

DTC P1171 – Fuel System Lean During Acceleration

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

Are any component-related DTCs set?

—

Go to

component

DTC charts

Go to

Step 3

3

1. Check the vehicle’s fuel tank for an adequate

amount of fuel.

2. Add fuel to the vehicle’s fuel tank if the tank is almost

empty.

Was fuel added to the vehicle’s fuel tank?

—

Go to

Step 4

Go to

Step 5

4

1. Place the transmission in park.

2. Using a Tech 2, observe HO2S 1 voltage while

running warm engine 75

°

C-95

°

C (167

°

F-203

°

F) at

1200 RPM.

3. HO2S 1 voltage should vary within the specified

range.

4. Quickly open the throttle too halfway for a few

seconds.

Did the voltage suddenly rise toward the high end of the

specified range?

100-900 mV

Go to

Fuel

System

Electrical Test

Go to

Step 5

5

1. Disconnect the fuel pump relay and crank the

engine to relieve the fuel pressure.

2. Install the fuel pressure gauge.

3. Start the engine and idle at normal operating

temperature.

4. Disconnect the vacuum line going to the fuel

pressure regulator.

With the engine running, is the fuel pressure within the

specified range?

280-325 kPa

(41-46 psi)

Go to

OBD

System

Check

Go to

Step 6

6

Check for restricted fuel lines or restricted in-line filter.

Was a problem found?

—

Verify repair

Go to

Step 7

7

1. Ignition “OFF”.

2. Remove the fuel pump relay and replace it with a

fused jumper which will connect the relay’s battery

terminal to the terminal leading to the fuel pump

fuse.

3. While the fuel pump is operating, use pliers to slowly

close the return line (do not exceed the first

specified value).

Using the pliers to restrict the return line, can the fuel

pressure be manipulated to exceed the second

specified value?

325 kPa

(46 psi)

414 kPa

(60 psi)

Go to

Diagnostic

Aids

Go to

Step 8

8

Check for:

D

Faulty fuel pump

D

Restricted fuel pump strainer (sock)

D

Incorrect fuel pump

D

Incorrect fuel being used

D

Hot fuel

Is the action complete?

—

Verify repair

—