Content .. 1135 1136 1137 1138 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1137

4A2–16

DIFFERENTIAL (REAR)

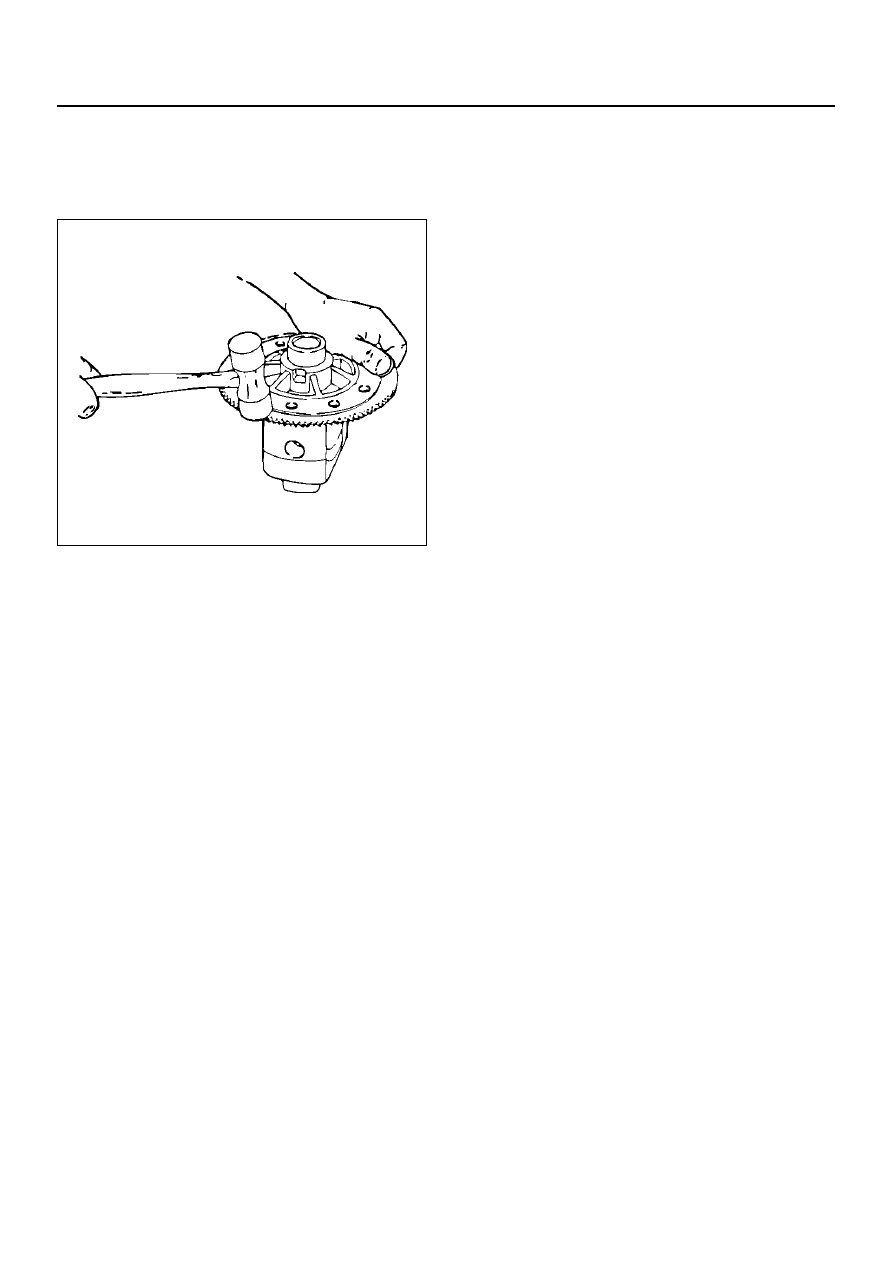

16. Remove exciter ring.

• Remove the exciter ring from the differential

using a mallet or a brass hammer if it is required.

NOTE: Discard the exciter ring after removal.

425RS097

Cleaning

Do not steam clean drive parts which have ground and

polished surfaces such as gears, bearings, and shafts.

These parts should be cleaned in a suitable solvent. All

parts should be disassembled before cleaning.

Parts should be thoroughly dried immediately after

cleaning. Use soft, clean, lintless rags. Parts may be

dried with cimpressed air. Do not allow the bearings to

spin while drying them with compressed air.

Inspection and Repair

It is very important to carefully and thoroughly inspect all

drive unit parts before reassembly.

Thorough inspection of the drive parts for wear or stress

and subsequent replacement of worn parts will

eliminate costly drive component repair after

reassembly.

Axle Housing

• The carrier bore for nicks or burrs that would prevent

the outer diameter of the pinion seal from sealing,

Remove any burrs that are found.

• The bearing cap bores for nicks or burrs.

Remove any burrs that are found.

• The housing for cracks. Replace the housing if any

cracks are found.

• The housing for foreign material such as metal chips,

dirt, or rust.

Pinion and Ring Gear

• Pinion and ring gear teeth for cracking, chipping,

scoring, or excessive wear.

• Pinion splines for wear.

• Pinion flange splines for wear.

• The sealing surface of the pinion flange for nicks,

burrs, or rough tool marks which would cause

damage to the seal's inside diameter and result in an

oil leak.

• Replace all worn or broken parts.

• Ring and pinion gears are matched sets and are both

replaced anytime a replacement of either is

necessary.

Bearings

• Bearings visually and by feel.

• The bearings should feel smooth when oiled and

rotated while applying as much hand pressure as

possible.

The large end of the bearing rollers for wear.

This is where tapered roller bearing wear is most

evident.

• Bearing cups for wear, cracks, brinelling and scoring.

• Bearing and cups are only replaced as sets.

• If the rear axle was operated for an extended period

of time with very loose bearings, the ring gear and

drive pinion will also require replacement.

• Low mileage bearings may have minute scratches

and pits on the rollers and the bearing cups from the

initial pre-load. Do not replace a bearing for this

reason.

• Bearing cups for cracks or chips.

Shims

• Shims for cracks and chips. Damaged shims should

be replaced with an equally sized service shim.