Isuzu Trooper (1998-2002 year). Manual - part 605

6E–68

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. Verifies that the fault is present.

3. If DTC P0118 can be repeated only by duplicating

the Failure Records conditions, refer to the

“Temperature vs. Resistance Value” table. The

table may be used to test the ECT sensor at various

temperatures to evaluate the possibility of a

“shifted” sensor that may be shorted above or below

a certain temperature. If this is the case, replace

the ECT sensor. If the ECT sensor appears to be

OK, the fault is intermittent; refer to

Diagnostic Aids.

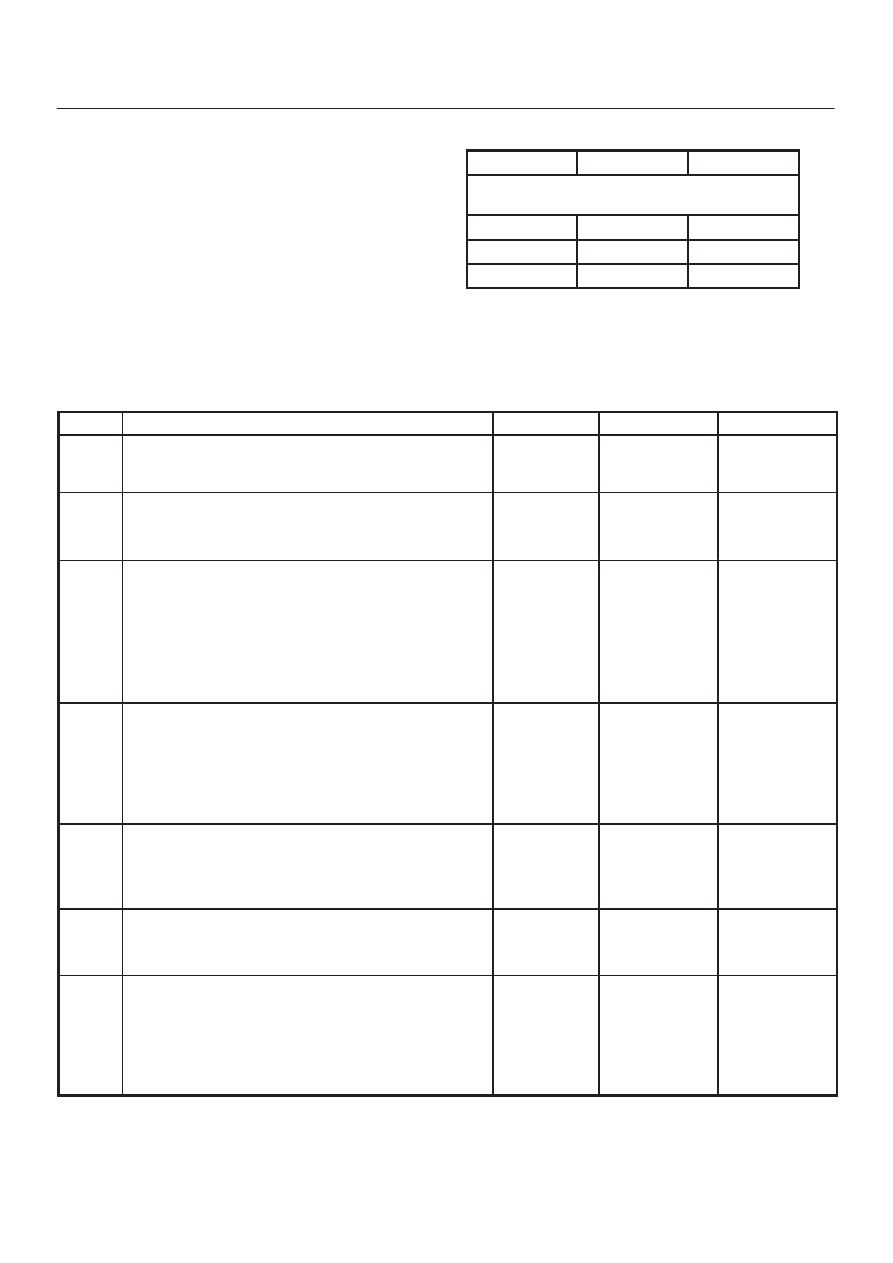

Engine Coolant Temperature Sensor

°

C

°

F

Ohms

Temperature vs. Resistance Values

(approximate)

80

176

332

25

77

2796

15

59

4450

DTC P0118 – ECT Sensor High Voltage

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

1. Ignition “ON,” engine “OFF.”

2. Observe the “Eng Cool Temp” display on the Tech 2.

Is the “Eng Cool Temp” below the specified value?

–39

°

C

(–38

°

F)

Go to

Step 4

Go to

Step 3

3

1. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor the “ DTC” info for DTC

P0118.

Does the Tech 2 indicate DTC P0118 failed?

—

Refer to

Test

Description

Refer to

Diagnostic

Aids

4

1. Disconnect the ECT sensor electrical connector.

2. Jumper the ECT signal circuit and the sensor

ground circuit together at the ECT sensor harness

connector.

3. Observe the “Eng Cool Temp” display on the Tech 2.

Is the “Eng Cool Temp” at the specified value?

140

°

C

(284

°

F)

Go to

Step 6

Go to

Step 5

5

1. Jumper the ECT signal circuit at the ECT sensor

harness connector to chassis ground.

2. Observe the “Eng Cool Temp” display on the Tech 2.

Is the “Eng Cool Temp” at the specified value?

140

°

C

(284

°

F)

Go to

Step 7

Go to

Step 8

6

Check for poor connections at the ECT sensor and

replace terminals if necessary.

Did any terminals require replacement?

—

Verify repair

Go to

Step 10

7

1. Ignition “OFF.”

2. Disconnect the ECM, and check the ECT sensor

ground circuit for an open.

3. If the ECT sensor ground circuit is open, repair it as

necessary.

Was the ECT sensor ground circuit open?

—

Verify repair

Go to

Step 9