Isuzu Trooper (1998-2002 year). Manual - part 306

6E–137

ENGINE DRIVEABILITY AND EMISSIONS

Disconnect the component while observing the TP

sensor display on the Tech 2. If the reading

changes drastically when this component is

disconnected, replace the component that affected

the reading.

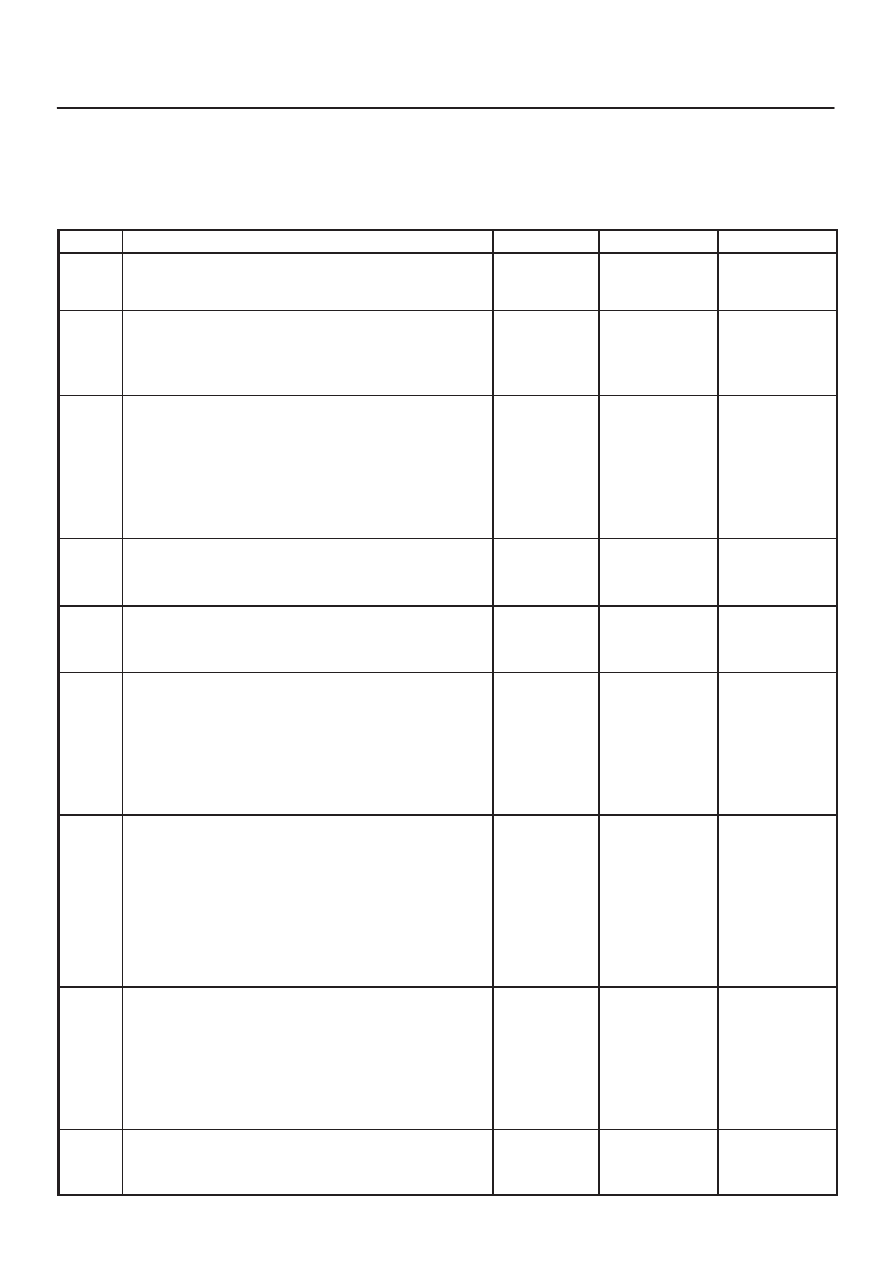

DTC P0123 – TP Sensor Circuit High Voltage

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

1. Ignition “ON,” engine “OFF.”

2. With the throttle closed, observe the “TP Sensor”

display on the Tech 2.

Is the “TP Sensor” above the specified value?

4.88 V

Go to

Step 4

Go to

Step 3

3

1. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor “Specific DTC” info for DTC

P0123.

Does the Tech 2 indicate DTC P0123 failed.

—

Go to

Step 4

Refer to

Diagnostic

Aids

4

1. Disconnect the TP sensor electrical connector.

2. Observe the “TP Sensor” display on the Tech 2.

Is the “TP Sensor” near the specified value?

0 V

Go to

Step 5

Go to

Step 6

5

Probe the sensor ground circuit at the TP sensor

harness connector with a test light connected to B+.

Is the test light “ON?”

—

Go to

Step 7

Go to

Step 10

6

1. Ignition “OFF,” disconnect the PCM.

2. Ignition “ON,” engine “OFF.”

3. Check for a short to voltage on the TP sensor signal

circuit.

4. If the TP sensor signal circuit is shorted, repair it as

necessary.

Was the TP sensor signal circuit shorted?

—

Verify repair

Go to

Step 12

7

1. Ignition “ON.”

2. Monitor the “TP Sensor” Tech 2 display while

disconnecting each of the components that share

the 5 volt reference “A” circuit (one at a time).

3. If the “TP Sensor” Tech 2 display changes, replace

the component that caused the display to change

when disconnected.

Does disconnecting any of these components cause

the “TP Sensor” display to change?

—

Verify repair

Go to

Step 8

8

1. Ignition “OFF,” disconnect the PCM.

2. Ignition “ON,” engine “OFF.”

3. Check for a short to B+ on the 5 volt reference “A”

circuit.

4. If the 5 volt reference “A” circuit is shorted, repair it

as necessary.

Was the 5 volt reference “A” circuit shorted?

—

Verify repair

Go to

Step 9

9

Check for poor electrical connections at the TP sensor

and replace terminals if necessary.

Did any terminals require replacement?

—

Verify repair

Go to

Step 11