Isuzu N-Series. Manual - part 934

Transmission Control System (Smoother) 7A-191

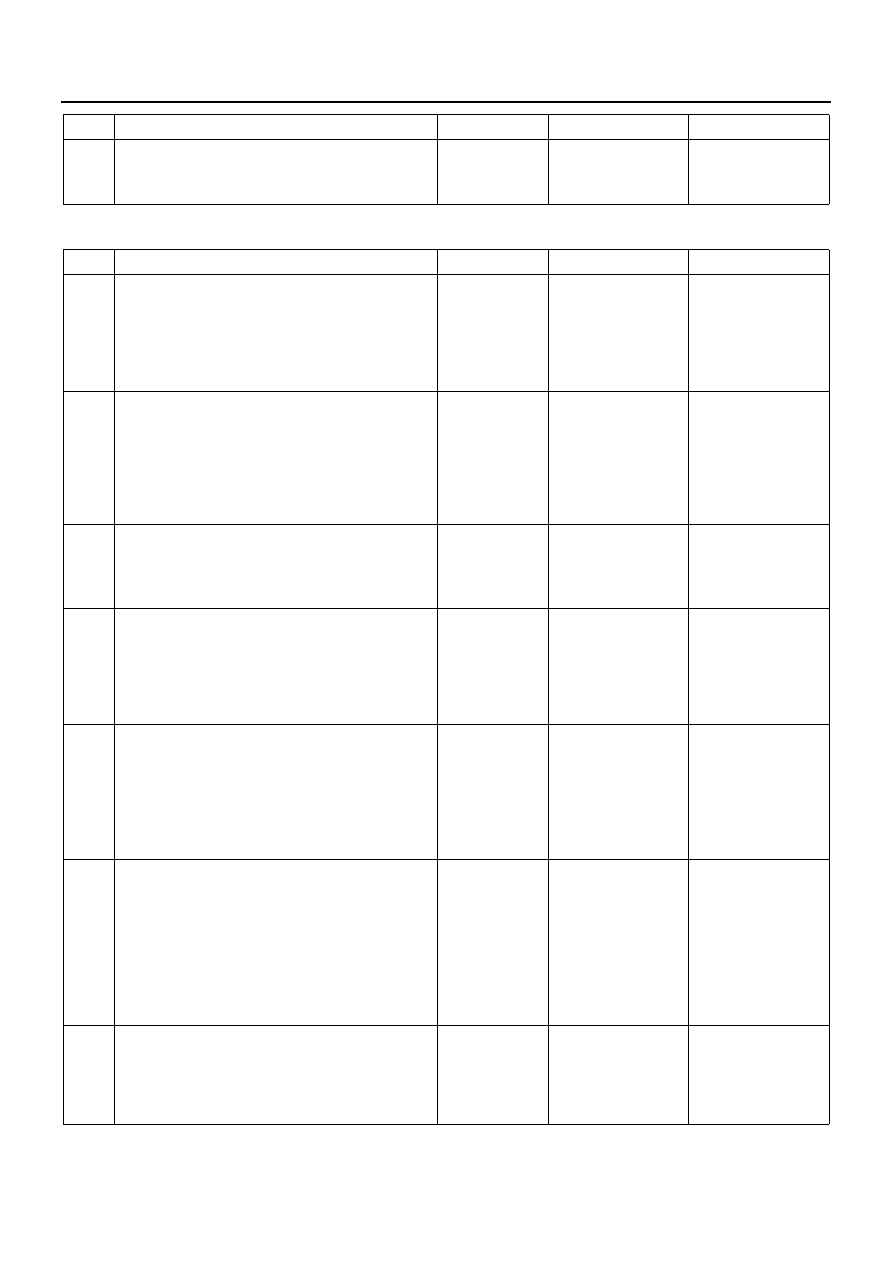

Chart 4 of 4

36

Reconnect all previously disconnected fuse or

harness connector(s).

Is the action complete?

—

Go to Chart 1 of 4

Step 6

—

Step

Action

Value(s)

Yes

No

Step

Action

Value(s)

Yes

No

1

1. Turn ON the ignition, with the engine OFF.

2. Observe the Brake Pedal Switch parameter

with the Tech 2.

Does the Brake Pedal Switch parameter indicate

Applied when the pedal is applied and Released

when the pedal is released?

—

Go to Intermittent

Conditions

Go to Step 2

2

1. Check to ensure the brake pedal switch is

adjusted correctly. The plunger should be all

the way in when the pedal is released, yet

should not impede with the brake pedal full

upward travel.

2. Adjust the brake pedal switch as necessary.

Did you find and correct the condition?

—

Go to Step 22

Go to Step 3

3

1. Turn OFF the ignition.

2. Inspect the Stop Light (10A) fuse (F-5) in the

glove box fuse block.

Is the Stop Light (10A) fuse (F-5) open?

—

Go to Step 4

Go to Step 5

4

Replace the Stop Light (10A) fuse (F-5). If the fuse

continues to open, repair the short to ground on one

of the circuits that is fed by the Stop Light (10A) fuse

(F-5) or replace the shorted attached component

fed by the Stop Light (10A) fuse (F-5).

Did you complete the repair?

—

Go to Step 22

—

5

1. Turn OFF the ignition.

2. Disconnect the brake pedal switch harness

connector.

3. Connect a test lamp between the voltage feed

circuit of the brake pedal switch harness (pin 1

of B-66 connector) and a known good ground.

Does the test lamp illuminate?

—

Go to Step 6

Go to Step 7

6

1. Turn ON the ignition, with the engine OFF.

2. Observe the Brake Pedal Switch parameter

with the Tech 2 while momentarily jumping 3-

amp fused jumper wire across the brake pedal

switch harness connector between pins 1 and

2 of the B-66 connector.

Does the Tech 2 indicate Applied when the circuit is

jumpered and Released when the circuit is not

jumpered?

—

Go to Step 9

Go to Step 8

7

Repair the open circuit or high resistance on the

voltage feed circuit between the Stop Light (10A)

fuse (F-5) and the brake pedal switch (pin 1 of B-66

connector).

Did you complete the repair?

—

Go to Step 22

—