Isuzu N-Series. Manual - part 922

Transmission Control System (Smoother) 7A-143

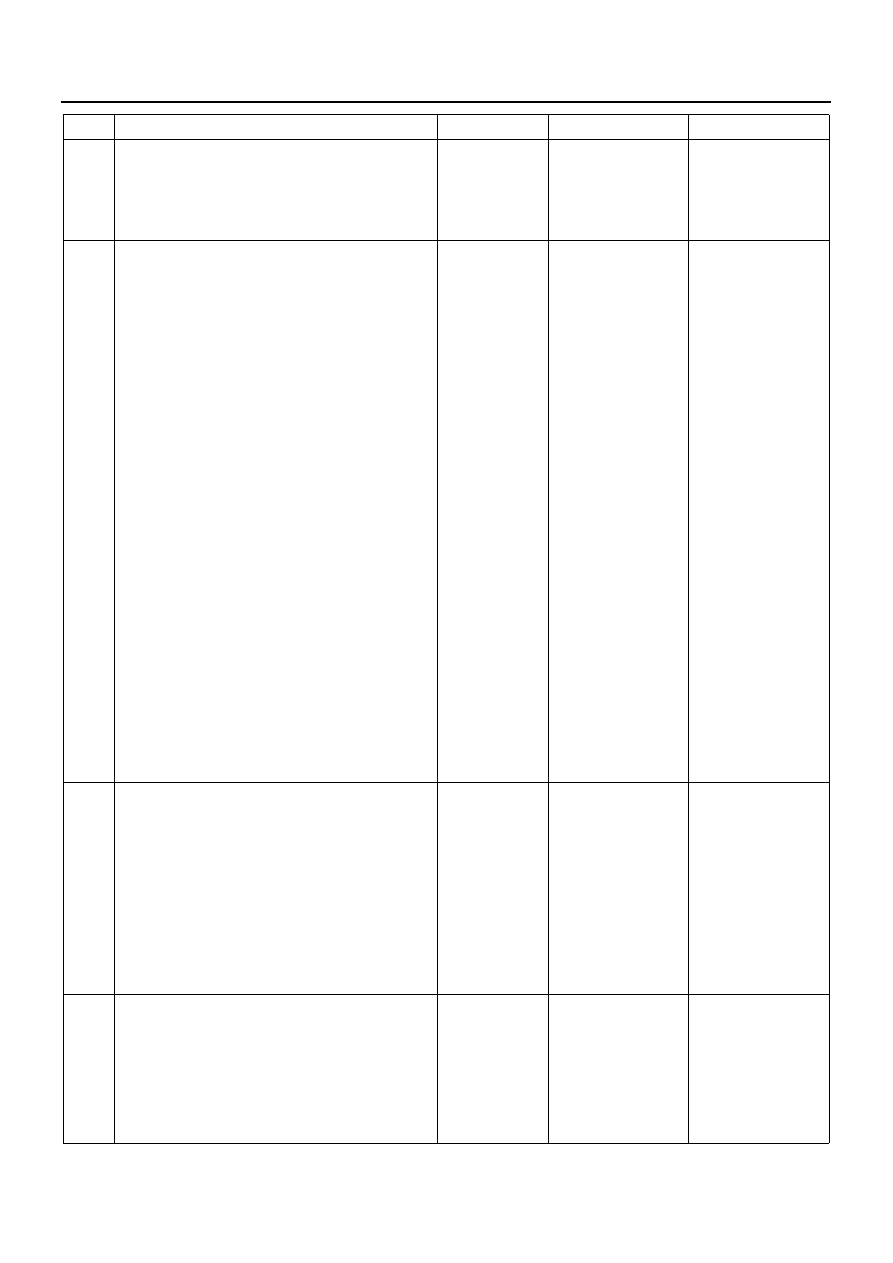

4

1. Lift the driving wheels or drive the vehicle.

2. Let the vehicle run so that all gear may engage

enough.

3. Monitor the DTC Information with the Tech 2.

Does the DTC fail this ignition?

—

Go to Step 5

Go to Diagnostic

Aids

5

1. Remove the gear shift position sensor. Refer

to Gear Shift Position Sensor Replacement in

this section.

2. Visually inspect the gear shift position sensor

for the following conditions:

• Physical damage

• Loose or improper installation

3. Inspect the gear shift position sensor output

voltage in order to check an open circuit, short

circuit and high resistance somewhere in the

operating range.

4. Remove the transmission gearshift control box

assembly from the transmission main unit.

Refer to Repair Instructions (Overhaul) -

Control Box in this section.

5. Visually inspect the shift side lever for the

following conditions:

• Shift lever damage that connects to the

gear shift position sensor shaft.

• Shift lever damage that connects to the

shift solenoid valves.

• Shift lever damage that connects to the

interlock plate and shift rods.

• Other damage that the shift lever possible

stuck.

6. Inspect the transmission main unit as

necessary. Refer to Repair Instructions

(Overhaul) in this section.

7. Repair or replace as necessary.

Did you find and correct the condition?

—

Go to Step 8

Go to Step 6

6

1. Remove the oil pump assembly. Refer to

Repair Instructions (Overhaul) - Oil Pump in

this section.

2. Inspect the oil pump and gearshift clutch for

the following conditions:

• The gearshift clutch solenoid valve for

mechanically stuck

• The clutch spool valve mechanically stuck

• The gearshift clutch mechanically stuck

3. Repair or replace as necessary.

Did you find and correct the condition?

Go to Step 8

Go to Step 7

7

Important:

Replacement 1-3-5 or 2-4-6-R shift solenoid valve

must be relearned.

Replace the 1-3-5 or 2-4-6-R shift solenoid valve.

Refer to Repair Instructions (Overhaul) - Gearshift

Control Box in this section.

Did you complete the replacement?

—

Go to Step 8

—

Step

Action

Value(s)

Yes

No