Isuzu N-Series. Manual - part 893

Transmission Control System (Smoother) 7A-27

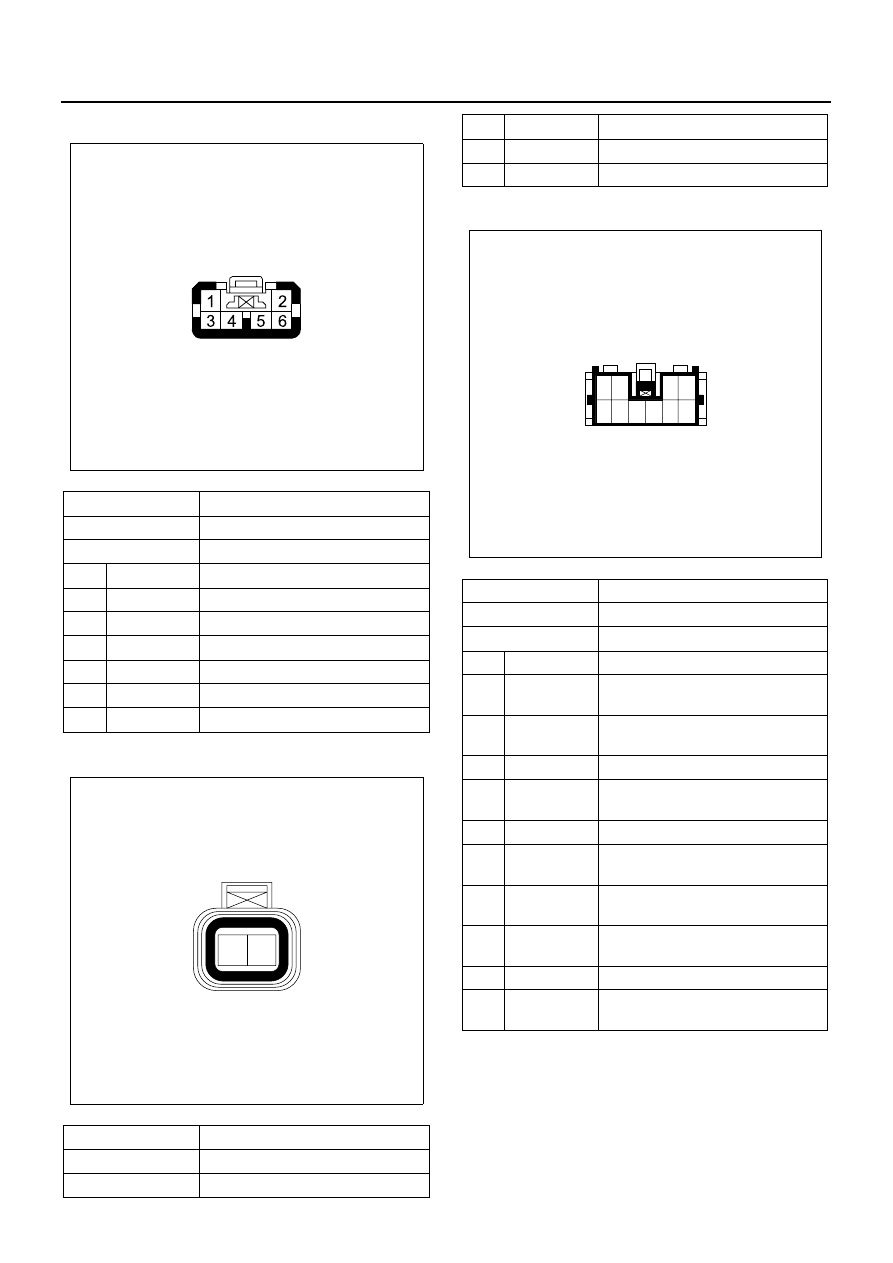

Reset Switch

Select Solenoid

Selector Lever

Connector No.

B-105

Connector Color

Black

Test Adapter No.

J-35616-4A

Pin

Wire Color

Pin Function

1

—

Not Used

2

—

Not Used

3

—

Not Used

4

BLK/ORN

Reset Switch Voltage Feed

5

—

Not Used

6

GRY/BLU

Reset Switch Signal

Connector No.

J-234

Connector Color

Green

Test Adapter No.

J-35616-42

N7A2113E

1

2

N7A2103E

Pin Wire

Color

Pin

Function

1

BLK

Select Solenoid Valve Ground

2

WHT/BLK

Select Solenoid Valve Control

Connector No.

N-19

Connector Color

White

Test Adapter No.

J-35616-33

Pin Wire

Color

Pin

Function

1

LT GRN/

RED

Illumination Lamp Voltage Feed

2

RED/BLK

Selector Lever “R” Position Switch

Signal

3

YEL/RED

1st Gear Start Switch Signal

4

GRN/BLK

Selector Lever “A” Position Switch

Signal

5

BLU

Economy Mode Switch Signal

6

WHT/BLK

Selector Lever “N” Position Switch

Signal

7

ORN

Selector Lever “D” Position Switch

Signal

8

PNK/BLK

Selector Lever “

−” Position Switch

Signal

9

BLK

Selector Lever Ground

10

BLU/BLK

Selector Lever “+” Position Switch

Signal

10

9

8

7

6

5

4

3

2

1

N7A2115E