Isuzu N-Series. Manual - part 724

6E-318 Engine Control System (4HK1)

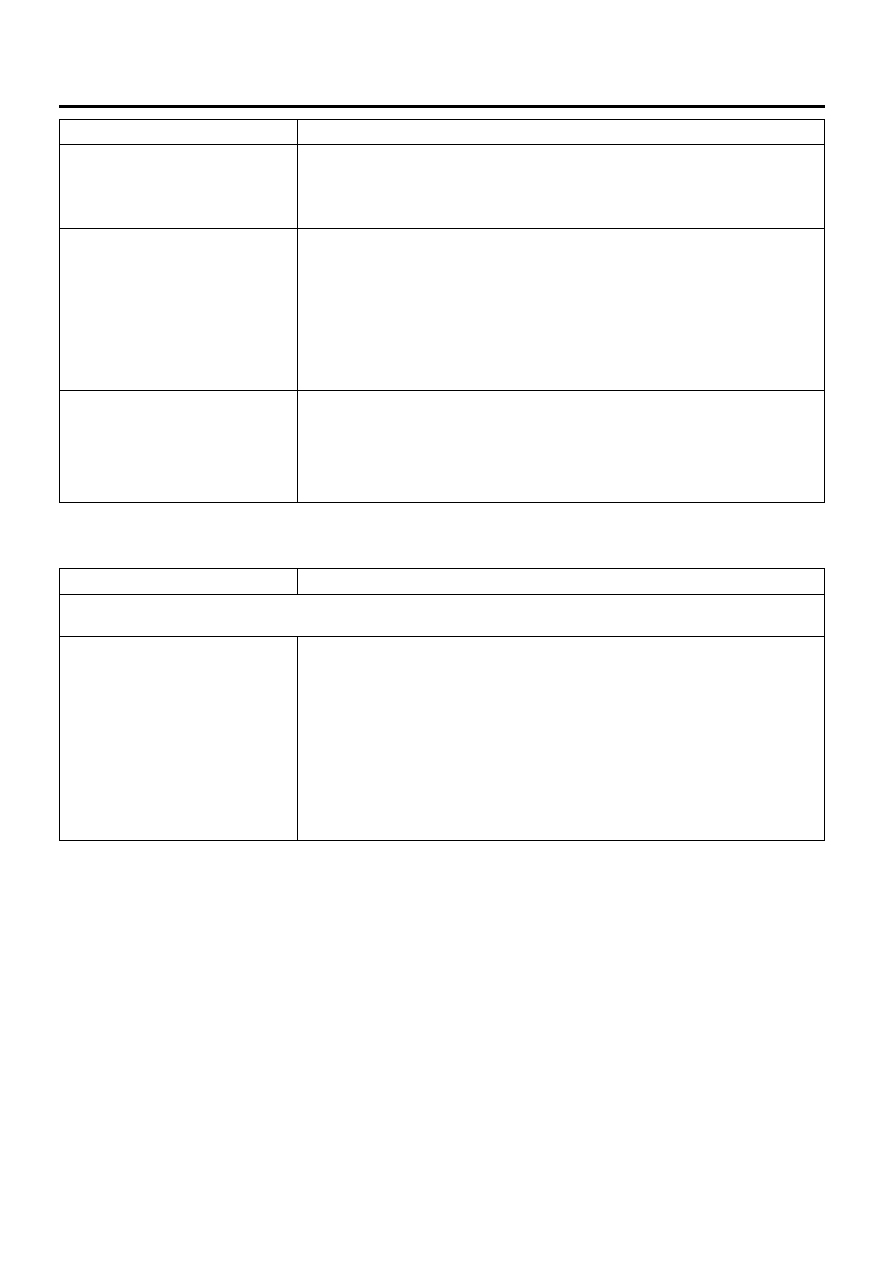

Surges / Chuggles

Exhaust System Checks

Inspect the exhaust system for a possible restriction. Refer to the Exhaust System

section.

• Inspect the exhaust brake valve for a stuck closed position.

• Inspect for a restriction in the exhaust pipes.

Engine Mechanical Checks

Inspect the engine mechanical for the following conditions. Refer to the Engine

Mechanical section.

• Inspect for poor cylinder compression. Proper compression is more than 1960 kPa

(284 psi) and variation of each cylinder is less than 294 kPa (43 psi).

• Improper valve timing

• Improper valve gap

• Broken or weak valve springs

• Worn camshaft lobes

Additional Checks

• Inspect the generator output voltage.

• Electromagnetic interference (EMI) on the reference circuit can cause an engine

miss condition. The Tech 2 can usually detect EMI by monitoring the engine speed.

A sudden increase in speed with little change in actual engine speed change

indicates that EMI is present. If a problem exists, check routing of high voltage

components, such as fuel injector solenoid wiring, near the sensor circuits.

Checks

Action

DEFINITION: The engine has a power variation under a steady throttle or cruise. The vehicle seems to speed up and slow

down with no change in the accelerator pedal.

Preliminary Checks

• Diagnostic System Check – Engine Controls.

• Ensure the driver understands the A/C compressor operation.

• Use the Tech 2 in order to make sure the Vehicle Speed parameter reading

matches the vehicle speedometer.

• Inspect the engine control module (ECM) grounds for being clean, tight, and in their

proper locations.

• Inspect that the harness connectors are correctly connected.

• Inspect the fuel type and quality.

• Inspect the programmed fuel injector ID code for each cylinder.

• Inspect the Tech 2 Data List in this section.

Checks

Action