Isuzu N-Series. Manual - part 717

6E-290 Engine Control System (4HK1)

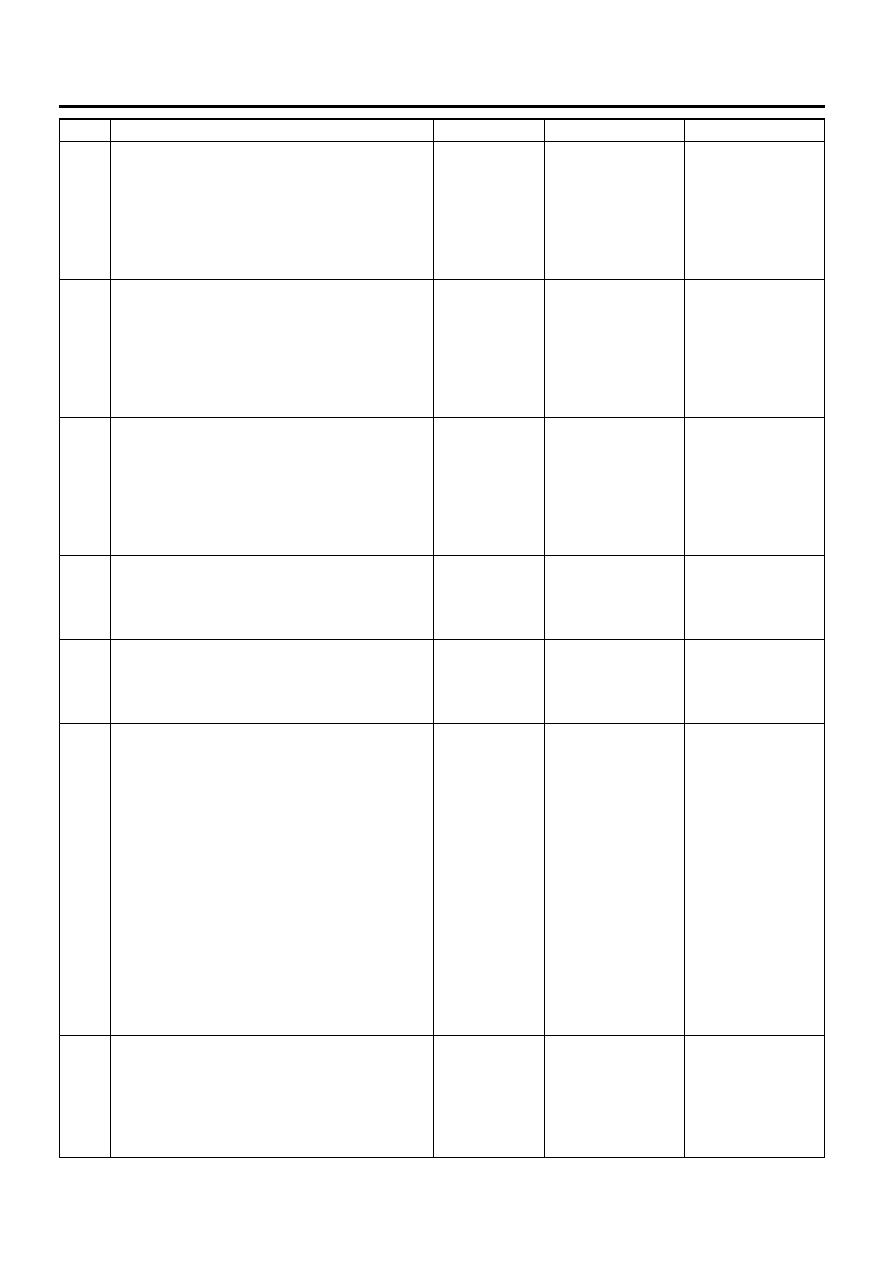

22

1.

Test for an open or high resistance in the CAN

Low or High circuit (which ever voltage

reading did not read between 1.3 – 3.7 volts in

Step 16) between the DRM and joint

connection.

2.

Repair the circuit(s) as necessary.

Did you find and correct the condition?

—

Go to Step 38

Go to Step 28

23

1.

Test for an open or high resistance in the CAN

Low or High circuit (which ever voltage

reading did not read between 1.3 – 3.7 volts in

Step 15) between the TCM and joint

connection.

2.

Repair the circuit(s) as necessary.

Did you find and correct the condition?

—

Go to Step 38

Go to Step 29

24

1.

Test for an open or high resistance in the CAN

Low or High circuit (which ever voltage

reading did not read between 1.3 – 3.7 volts in

Step 17) between the ECM and joint

connection.

2.

Repair the circuit(s) as necessary.

Did you find and correct the condition?

—

Go to Step 38

Go to Step 31

25

Repair the short circuit each other across the CAN

Low and High circuits among the resistor 1, TCM

and EHCU.

Did you complete the repair?

—

Go to Step 38

—

26

Repair the short circuit each other across the CAN

Low and High circuits among the resistor 2, ECM,

DRM and EHCU.

Did you complete the repair?

—

Go to Step 38

—

27

1.

Test the CAN Low and High circuits between

the resistor 1 (pins 1 and 2 of B-387

connector) and the EHCU (pins 14 and 15 of

J-177 connector) for an open circuit or high

resistance.

2.

Test the CAN Low and High circuits between

the resistor 2 (pins 1 and 2 of B-431

connector) and the EHCU (pins 26 and 27 of

J-177 connector) for an open circuit or high

resistance.

3.

Inspect for an intermittent, for poor

connections and corrosion on the CAN Low

and High circuits at the harness connector of

the each resistor.

4.

Repair the circuit(s) or connection(s) as

necessary.

Did you find and correct the condition?

—

Go to Step 38

Go to Step 30

28

1.

Inspect for an intermittent, for poor

connections and corrosion on the CAN Low

and High circuits at the harness connector of

the DRM (pins 2 and 8 of B-429 connector).

2.

Repair the connection(s) as necessary.

Did you find and correct the condition?

—

Go to Step 38

Go to Step 34

Step

Action

Value(s)

Yes

No