Isuzu N-Series. Manual - part 709

6E-258 Engine Control System (4HK1)

P1630 (Flash Code 36)

Circuit Description

This diagnostic applies to internal microprocessor

integrity conditions within the engine control module

(ECM).

Condition for Setting the DTC

• The ECM detects a malfunction in its internal

analog / digital (A/D) converter.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicator

lamp (MIL) when the diagnostic runs and fails.

• The ECM limits accelerator control range.

• The ECM inhibits pilot injection.

Condition for Clearing the MIL / DTC

• The ECM turns OFF the MIL when the key is

cycled after a current DTC clears.

• A current DTC clears when the diagnostic runs and

does not fail.

• A history DTC clears after 20 consecutive driving

cycles without a fault. Or clear with the Tech 2 or

accelerator pedal operation.

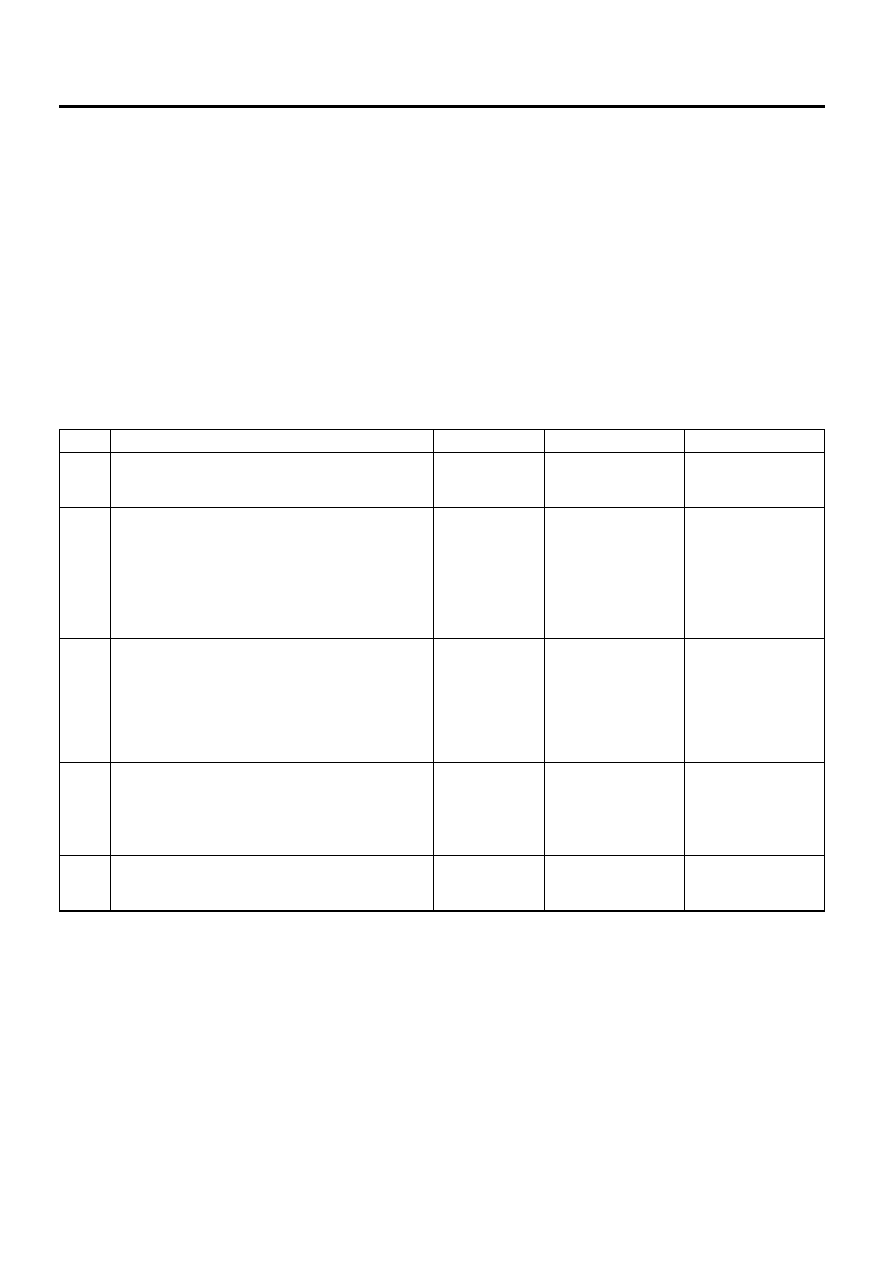

DTC P1630 (Flash Code 36)

Step

Action

Value(s)

Yes

No

1

Did you perform the Diagnostic System Check –

Engine Controls?

—

Go to Step 2

Go to Diagnostic

System Check –

Engine Controls

2

1.

Install the Tech 2.

2.

Turn OFF the ignition for 30 seconds.

3.

Start the engine.

4.

Monitor the Diagnostic Trouble Code (DTC)

Information with the Tech 2.

Does the DTC fail this ignition?

—

Go to Step 3

Go to Step 4

3

Important:

Replacement ECM must be programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement / Fuel Injector ID Code Data

Programming in this section.

Did you complete the replacement?

—

Go to Step 4

—

4

1.

Clear the DTCs with the Tech 2.

2.

Turn OFF the ignition for 30 seconds.

3.

Start the engine.

Did the DTC fail this ignition?

—

Go to Step 3

Go to Step 5

5

Observe the DTC Information with the Tech 2.

Are there any DTCs that you have not diagnosed?

—

Go to Diagnostic

Trouble Code (DTC)

List

System OK