Isuzu N-Series. Manual - part 680

6E-142 Engine Control System (4HK1)

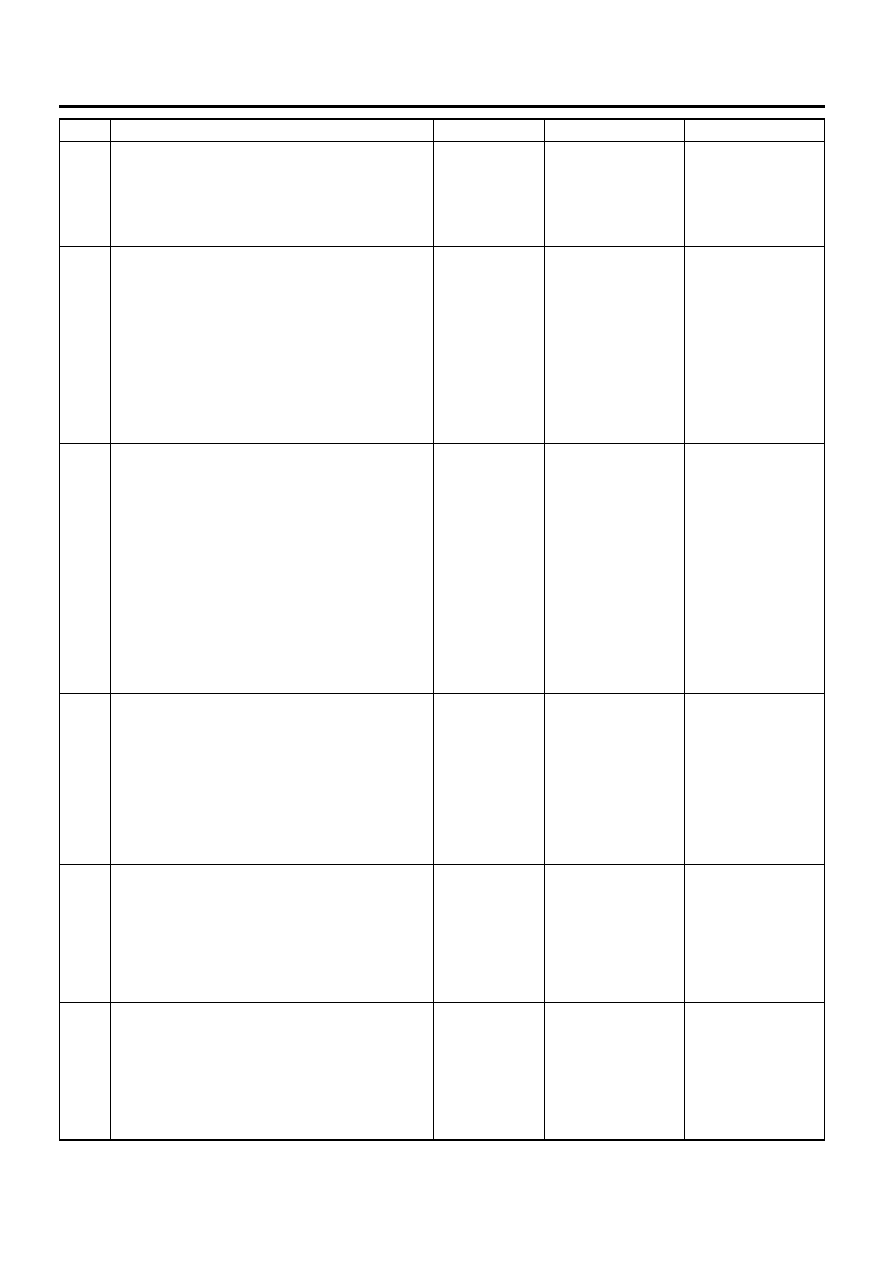

6

1.

Inspect for an intermittent and for a poor

connection at the in-line harness connector

(pin 8 of H-125 connector).

2.

Repair the connection(s) as necessary.

Did you find and correct the condition?

—

Go to Step 15

Go to Step 7

7

1.

Remove the cylinder head cover. Refer to Fuel

Injector Replacement in this section.

2.

Inspect the fuel injector harness for loose

injector terminal nuts, objects touching injector

terminals.

3.

Inspect for an intermittent and for a poor

connection at the in-line harness connector

(pin 8 of H-126 connector).

4.

Repair the connection(s) as necessary.

Did you find and correct the condition?

—

Go to Step 15

Go to Step 8

8

1.

Test the cylinder number 4 fuel injector

solenoid control circuit between the fuel

injector terminal (pins 1, 2 and 3 of E-141

connector) and the in-line harness connector

(pins 1, 4 and 8 of H-126 connector) for the

following conditions:

• An open circuit

• A short to the common 1 fuel injector

drive circuit

• High resistance

2.

Repair or replace the injector harness as

necessary.

Did you find and correct the condition?

—

Go to Step 15

Go to Step 13

9

1.

Test the cylinder number 4 fuel injector

solenoid control circuit and common 1 fuel

injector drive circuit for a short to each other

between the engine control module (ECM)

(pins 117 and 121 of E-111 connector) and the

in-line harness connector (pins 1 or 4 and 8 of

H-125 connector).

2.

Repair the circuit(s) as necessary.

Did you find and correct the condition?

—

Go to Step 15

Go to Step 14

10

1.

Test the cylinder number 4 fuel injector

solenoid control circuit between the ECM (pin

117 of E-111 connector) and the in-line

harness connector (pin 8 of H-125 connector)

for a short to battery or ignition voltage.

2.

Repair the circuit(s) as necessary.

Did you find and correct the condition?

—

Go to Step 15

Go to Step 14

11

1.

Test the cylinder number 4 fuel injector

solenoid control circuit between the ECM (pin

117 of E-111 connector) and the in-line

harness connector (pin 8 of H-125 connector)

for an open circuit or high resistance.

2.

Repair the circuit(s) as necessary.

Did you find and correct the condition?

—

Go to Step 15

Go to Step 12

Step

Action

Value(s)

Yes

No