Isuzu N-Series. Manual - part 677

6E-130 Engine Control System (4HK1)

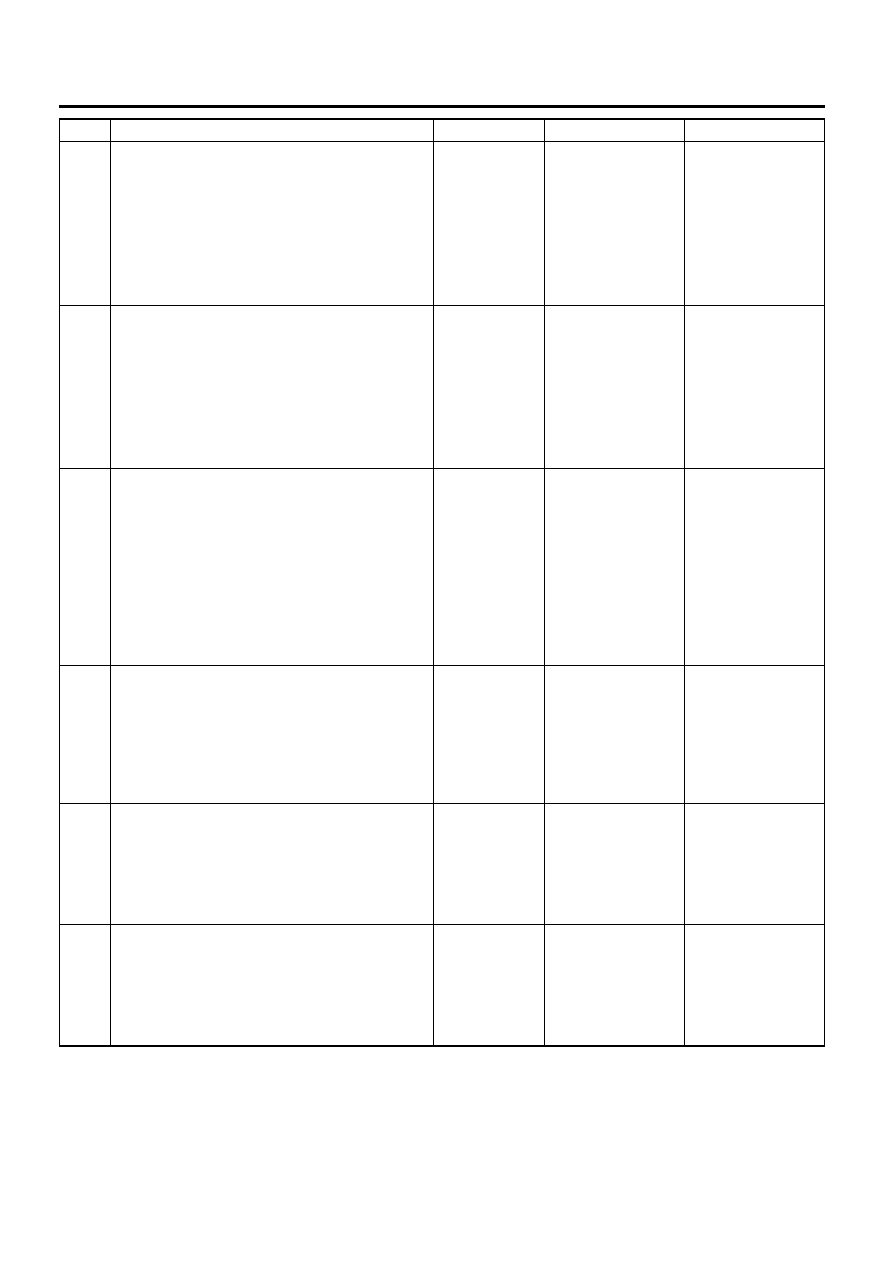

4

1.

Turn OFF the ignition.

2.

Disconnect the FRP sensor harness

connector.

3.

Connect a DMM between the signal circuit of

the FRP sensor harness (pin 2 of E-113

connector) and a known good ground.

4.

Turn ON the ignition, with the engine OFF.

Is the DMM voltage more than specified value?

5.5 volts

Go to Step 10

Go to Step 5

5

1.

Turn OFF the ignition.

2.

Connect a test lamp between the signal circuit

of the FRP sensor harness (pin 2 of E-113

connector) and a known good ground.

3.

Connect a DMM between the probe of the test

lamp and a known good ground.

4.

Turn ON the ignition, with the engine OFF.

Is the DMM voltage more than the specified value?

4.5 volts

Go to Step 9

Go to Step 6

6

1.

Turn OFF the ignition.

2.

Connect a 3-amp fused jumper wire between

the signal circuit and the low reference circuit

of the FRP sensor harness (pins 1 and 2 of E-

113 connector).

3.

Turn ON the ignition, with the engine OFF.

4.

Observe the FRP Sensor parameter with the

Tech 2.

Is the FRP Sensor parameter less than the

specified value?

0.7 volts

Go to Step 11

Go to Step 7

7

1.

Test the low reference circuit between the

engine control module (ECM) (pin 101 of E-

111 connector) and the FRP sensor (pin 1 of

E-113 connector) for an open circuit or high

resistance.

2.

Repair the circuit(s) as necessary.

Did you find and correct the condition?

—

Go to Step 15

Go to Step 8

8

1.

Test the signal circuit between the ECM (pins

82 and 90 of E-111 connector) and the FRP

sensor (pin 2 of E-113 connector) for an open

circuit or high resistance.

2.

Repair the circuit(s) as necessary.

Did you find and correct the condition?

—

Go to Step 15

Go to Step 12

9

1.

Test the signal circuits between the ECM (pins

82 and 90 of E-111 connector) and the FRP

sensor (pin 2 of E-113 connector) for a short to

any 5 volts reference circuit.

2.

Repair the circuit(s) as necessary.

Did you find and correct the condition?

—

Go to Step 15

Go to Step 14

Step

Action

Value(s)

Yes

No