Isuzu N-Series. Manual - part 635

ENGINE ELECTRICAL 6D-33

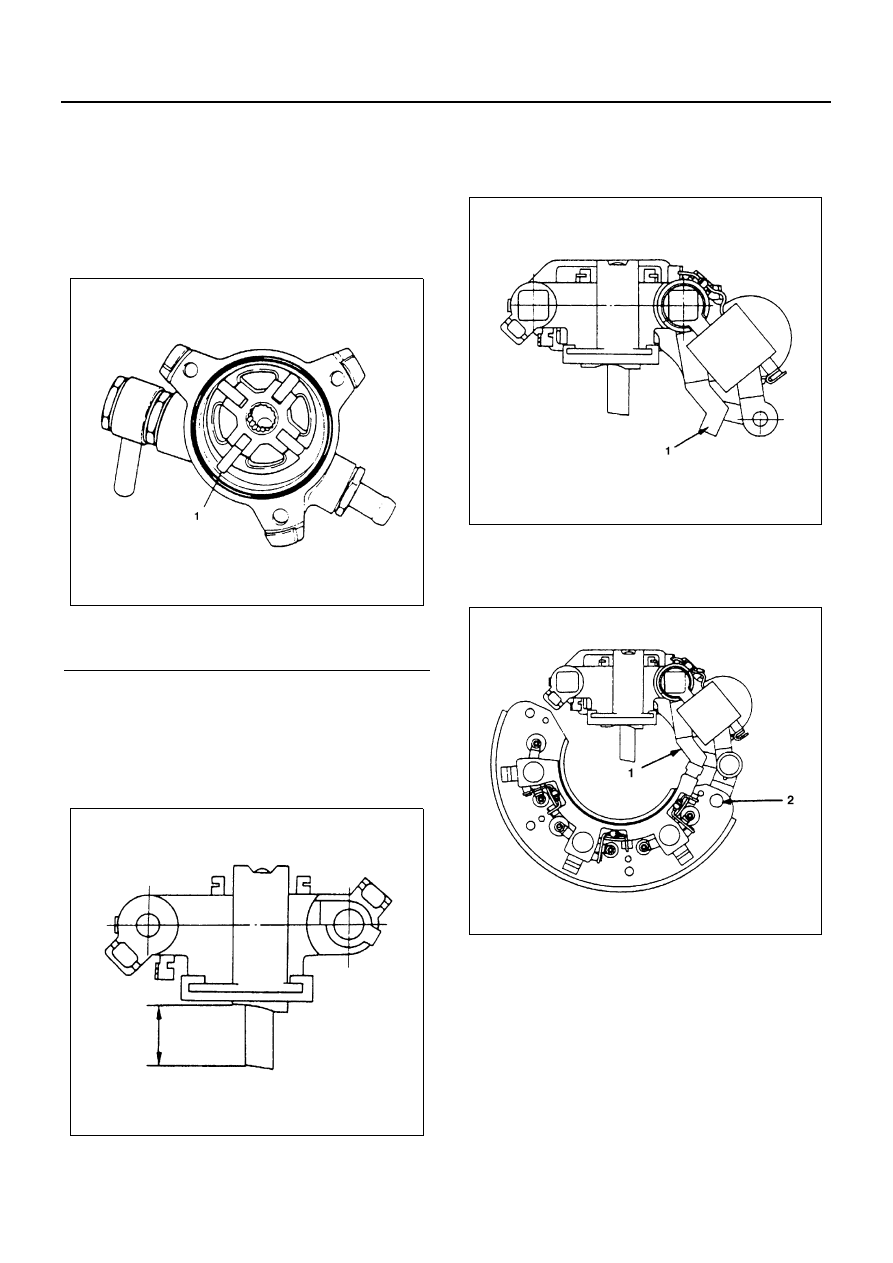

Reassembly of Vacuum Pump

1. Position the rotor, with the serrated boss turned up,

on the center plate and housing.

Align the holes in center plate and rotor.

2. Install vanes into slits in rotor.

The vanes should be installed with chamfered side

turned outward.

3. Install the O-ring and center plate

Reassembly

1. Brush Holder

2. IC Regulator Assembly

• Hold the brush in the holder as shown in the il-

lustration and solder the lead wire.

• Put the IC regulator on the brush holder and

press the bolt.

Bushing and connecting plate (1) must be in-

stalled when pressing the bolt.

3. Diode

• Connect the terminals by fixing the rivet at (1)

and soldering the terminal at (2).

4. Stator

• When connecting stator coil leads and diode

leads using solder, use long-nose pliers and

finish the work as quickly as possible to prevent

the heat from being transferred to the diodes.

Legend

1. Chamfered side

N6A3547E

N6A3548E

N6A3549E

N6A3550E