Isuzu N-Series. Manual - part 631

ENGINE ELECTRICAL 6D-17

Reassembly

To install, follow the removal steps in the reverse order,

noting the following points:

• Magnetic Switch

• Idle Gear

• Clutch assembly

• Housing

1. Install the clutch asm to the magnetic switch.

2. Install the idle gear and housing.

Notice:

Do not fail to assemble the steel ball and the spring be-

tween the clutch and magnetic switch.

Assemble the roller to the idle gear in advance.

Magnetic Switch

Temporarily connect the solenoid switch between the

clutch and the housing and run the following tests.

Complete each test within three to five seconds.

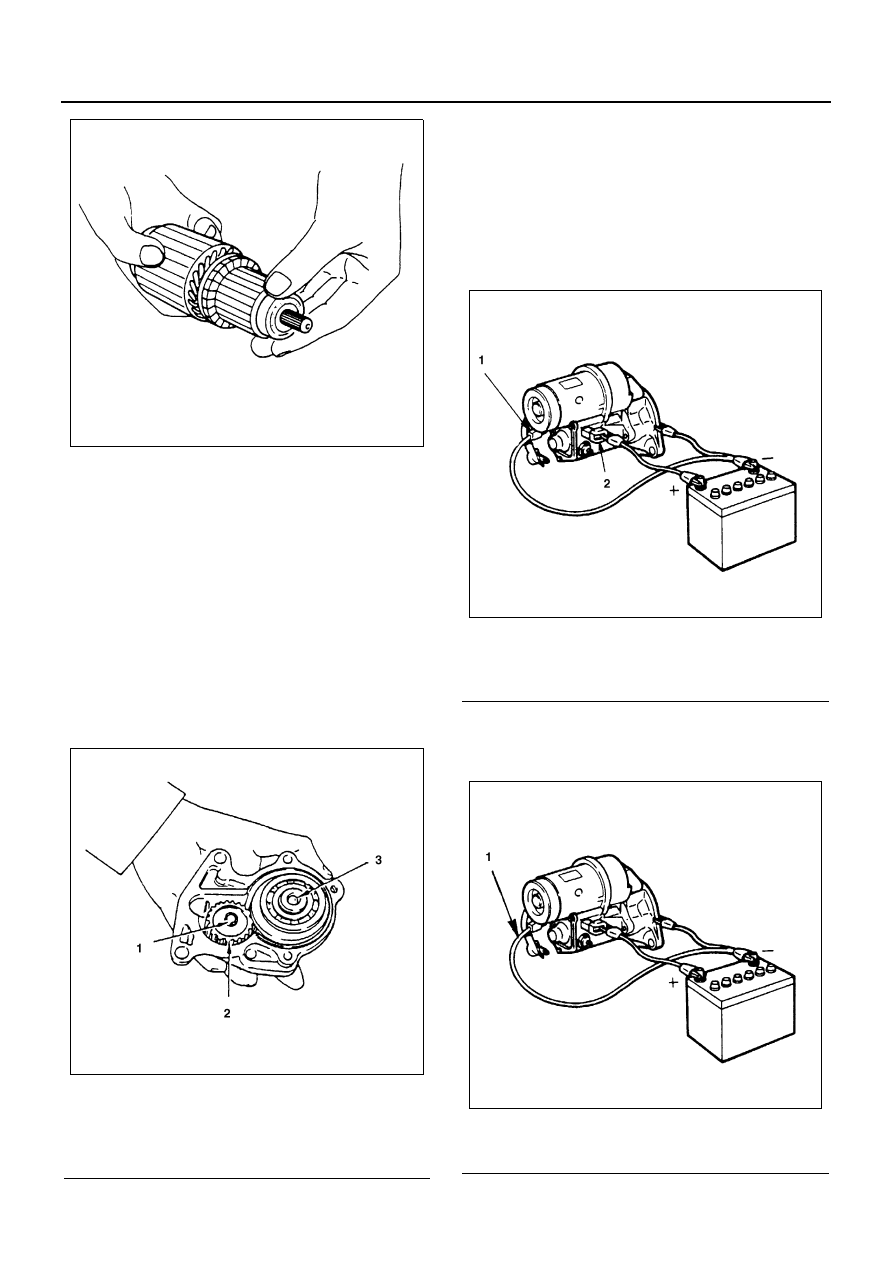

1. Pull-in test

Connect the battery negative terminal with the so-

lenoid switch body and the M terminal. When cur-

rent is applied to the 50 terminal from the battery

positive terminal, the pinion should flutter.

2. Hold-in test

Disconnect the lead at the M terminal. The pinion

should continue to flutter.

Legend

1. Roller

2. Idle gear

3. Steel ball

N6A3514E

N6A3515E

Legend

1. M terminal

2. 50 terminal

Legend

1. Disconnect

N6A3516E

N6A3517E